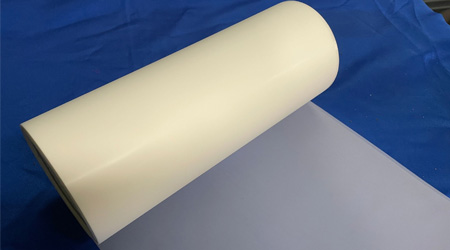

Film – PET film is used in the DTF printing process. These films are different from those used for screen printing. They are about 0.75mm thick and have better transmission characteristics. In marketing language, these are often referred to as DTF transfer films. DTF film is available in cut sheets (available for small-scale use) and rolls (for use with commercial installations). Another classification of PET films is based on the type of peel after transfer. Depending on the temperature, the film can be either a hot-peel or cold-peel film.

Insert PET film into the printer tray instead of plain paper. First print the entire image in white on PET film. After this, print the desired image on the white image layer using the appropriate color settings in the printer. The important thing to remember is that the print on the film must be a mirror image of the actual image that needs to appear on the fabric.

Insert PET film into the printer tray instead of plain paper. First print the entire image in white on PET film. After this, print the desired image on the white image layer using the appropriate color settings in the printer. The important thing to remember is that the print on the film must be a mirror image of the actual image that needs to appear on the fabric.

DTF Film Feature List

-

Pet film with high ink absorption, easy to clean powder.

Pet film with high ink absorption, easy to clean powder. -

There are different sizes, 60cm and 30cm pet film for choose.

There are different sizes, 60cm and 30cm pet film for choose. -

Wide applications, T-shirts, bags, shoes, wood panels, etc.

Wide applications, T-shirts, bags, shoes, wood panels, etc. -

The DTF film Pass SGS certification, meet the requirements, harmless to human body.

The DTF film Pass SGS certification, meet the requirements, harmless to human body. -

Surface is coated with matte release agent, smooth without wrinkles.

Surface is coated with matte release agent, smooth without wrinkles. -

High temperature resistance, low thermal shrinkage, easy to demould.

High temperature resistance, low thermal shrinkage, easy to demould.