If you are looking to push the boundaries of product customization, Direct-to-Film (DTF) and UV Printing on TPU (Thermoplastic Polyurethane) film are the two technologies you need to watch. Both offer stunning, high-definition results, but they serve different creative purposes.

Whether you are branding high-end tech accessories or creating flexible apparel transfers, here is why this combination is taking the industry by storm.

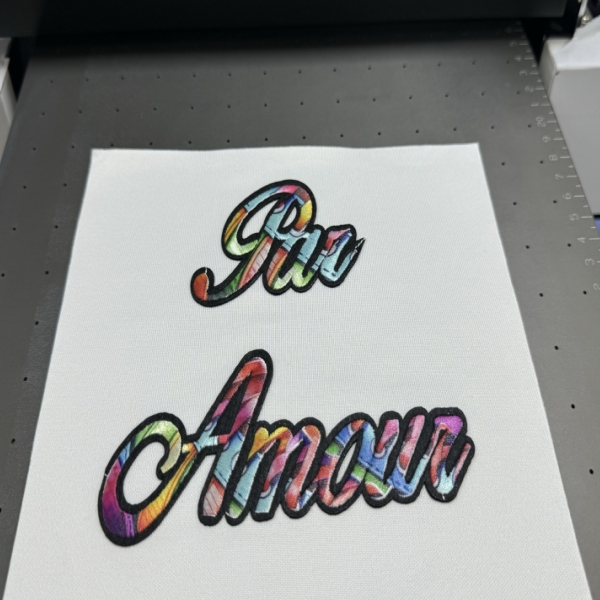

1. DTF on TPU: The King of Flexibility

Direct-to-Film technology has revolutionized the textile industry, but when paired with TPU film, it reaches a new level of durability. TPU is naturally elastic, making it the perfect “bridge” for designs that need to move.

-

Soft-Hand Feel: DTF prints on TPU film are incredibly thin and flexible. They don’t feel like a heavy plastic “sticker” on clothing; they feel like part of the fabric.

-

Vibrant Color Depth: DTF allows for a high-density white ink base, ensuring that your festive reds and deep blues remain vivid even on dark surfaces.

-

Stretch Resistance: Unlike traditional vinyl, a TPU-based DTF transfer can be stretched repeatedly without cracking, making it ideal for performance wear and activewear.

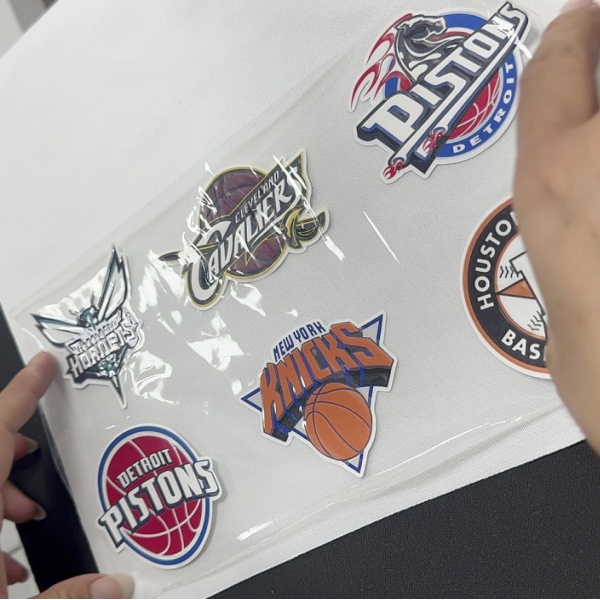

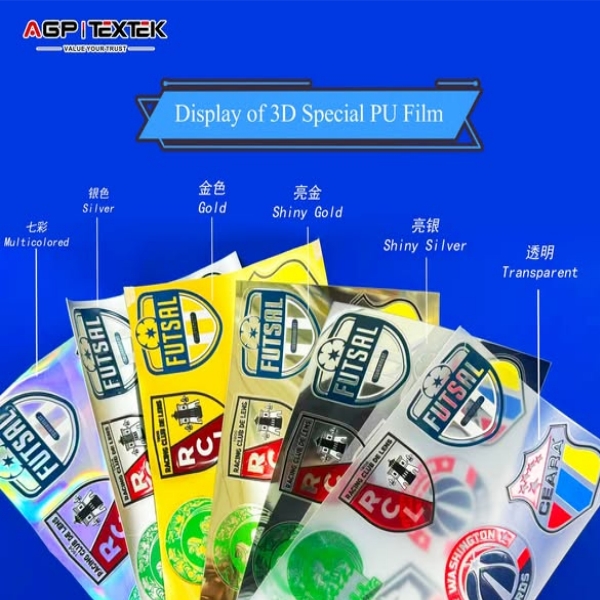

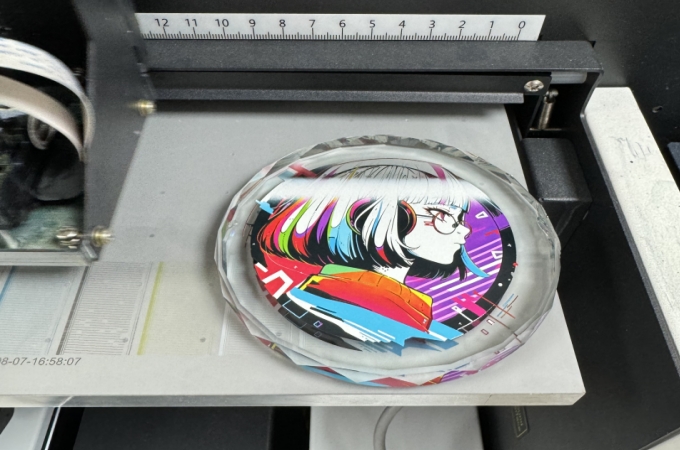

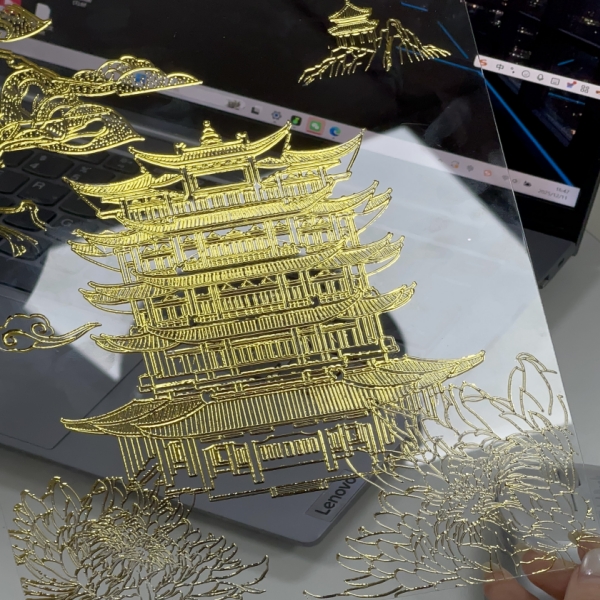

2. UV Printing on TPU: Precision and Texture

UV printing takes a different approach by using UV light to instantly cure ink onto the TPU surface. This is the go-to method for hard-surface customization and high-end labeling.

-

3.5D Embossed Effects: One of the most “stunning” features of UV printing is the ability to layer clear gloss ink to create tactile, raised textures. You can literally feel the design.

-

Curved Surface Versatility: UV TPU “stickers” (often called Crystal Stickers) are incredibly thin. Because TPU is so conformable, these stickers can be applied to irregular and curved surfaces—like water bottles, helmets, and rounded electronics—where traditional flatbed printing can’t reach.

-

Instant Durability: UV inks are scratch-resistant, waterproof, and UV-resistant immediately after curing, ensuring your branding stays perfect for years.

Which One Suits Your Project?

-

Choose DTF if your goal is wearable comfort. It is the best choice for t-shirts, hoodies, and fabric-based accessories where a soft, breathable finish is the priority.

-

Choose UV if your goal is premium branding. It excels at creating high-end, durable labels for electronics, glass, and industrial equipment.

.jpg)

.jpg)