When you receive the DTF ink, you must first remove it from the box and make sure that the outer packaging of the ink is sealed. Do not expose the unopened ink to air as this will affect the life of the ink. After confirmation, you can put the ink back in the box for storage.

After that, we need to store the ink in a dry, cool place away from direct sunlight. Storing it directly in the carton can avoid moisture, water intrusion, high temperature and direct sunlight. Direct sunlight will cause the surface temperature of the ink’s outer packaging to rise, which will cause the temperature of the ink itself to rise, affecting the usability and storage life of the ink.

DTF ink is divided into white ink and colored ink. Since the main component of white ink is titanium dioxide, it will precipitate if left for a long time, so the storage time of white ink will be shorter than that of color ink.

Under normal circumstances, the storage time of white ink is 6 to 9 months, and the storage time of color ink is 9 to 12 months. However, it is best to use it within 6 months. If the ink is not used completely after opening, the bottle cap must be tightened and the ink must be used within 15 days.

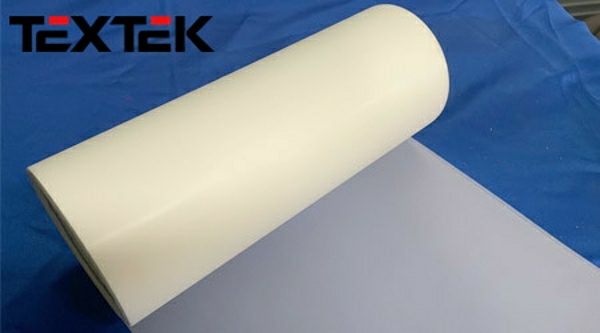

Therefore, there are two common specifications of white heat transfer ink in the market, 1000ml and 500ml, and there is also a small specification of 100ml.

Manufacturers can choose the appropriate specification of ink according to their actual situation. It is especially important to note that because white ink will precipitate if left for a long time, it must be shaken vigorously back and forth before opening the lid for use, and then poured into the ink barrel for use. It is recommended that you use an ink shaker to shake the white ink thoroughly and evenly before opening it for use.

In addition, you can put a time label on the ink after receiving the goods and opening the package, so that the time is clear at a glance, and it is also more convenient to see the inventory so that you can purchase goods in time without delaying the production process. The ink in the ink tank of the white ink thermal transfer printer must also be stored correctly.

First of all, the DTF ink thermal transfer printer must be used frequently to keep the ink channel of the printer clear and the ink flowing smoothly. Second, after not using the white ink thermal transfer printer for a long time, you should check the ink status in the ink cartridge. If the ink condition is not good, you must replace the ink with new ink before working again; in addition, before working, you must first turn on the white ink circulation device of the white ink thermal transfer printer, and stir the white ink evenly before starting to work.

The ability of the white ink thermal transfer printer to print vibrant color patterns is inseparable from the high quality of the white ink thermal transfer ink, so the proper storage of the ink is an indispensable part of daily work.