Reasons why your heat transfer film is difficult to tear

1. The hot stamping temperature is not correct. The hot stamping machine must be set to the correct temperature in advance.

2. The hot stamping pressure is not enough. The hot stamping pressure should be increased. The higher the pressure, the better the hot stamping effect.

3. The film peeling method is not considered correctly. The hot stamping film is used as a cold stamping film, or the cold stamping film is used as a hot stamping film. When using it, it is necessary to distinguish between cold tear film and hot tear film.

In summary, the exact temperature, time and pressure should be formulated according to the characteristics of different fabrics. These are the three elements of hot stamping.

4 Basic Elements for Selecting DTF Heat Transfer Film

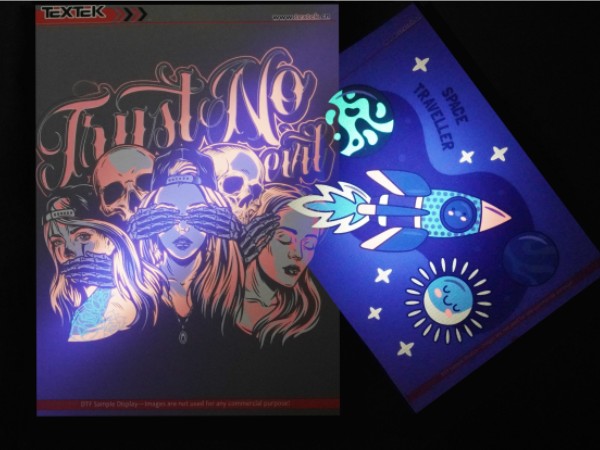

1. The pattern after hot stamping has a texture like PU glue, strong elasticity and no deformation, and feels softer than glue (30~50% softer than the pattern printed by oily coating film).

2. It is suitable for most inks in the market, and 100% of the ink volume can be printed at will, without ink gathering or ink flow.

3. The surface of the film is dry and can be sprinkled with 50-200 mesh powder without sticking to the powder. The image is the image, the powder is the powder, the place with ink sticks to the powder, and the place without ink is clean.

4. The release is easy and clean, the printed film does not leave ink, and the pattern does not leave a layer.

.jpg)