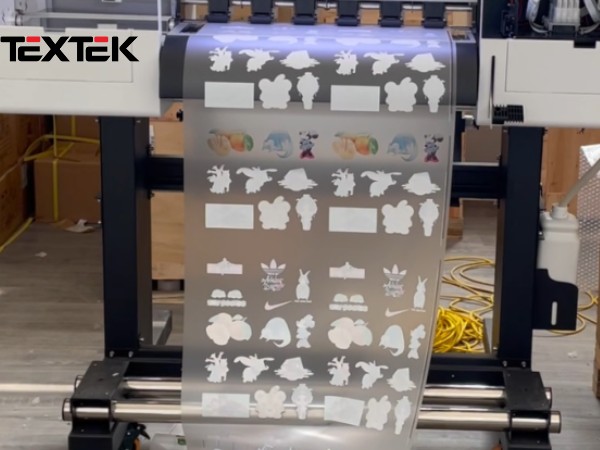

The working principle of the powder shaking machine is not complicated. Its main working process is powder sprinkling, powder shaking, and powder drying. Firstly, the hot melt adhesive powder is evenly sprinkled on the heat transfer pattern, then the excess hot melt adhesive powder is shaken off, and finally, the heat transfer pattern sprinkled with hot melt adhesive powder is dried. After understanding the basic operation of the powder shaking machine, let’s analyze the reasons why the powder is not shaken cleanly.

1. Ink problem

If the white ink is too thin and the water content is high, it is easy to cause ink flow (the oil and water of the white ink seep over the edge of the pattern), which will cause too much hot melt powder to stick to the edge of the pattern when shaking the powder. Note: If there are water spots around the printed film pattern before the powder is applied, it can be determined that it is an ink problem.

Replacing the ink or pre-drying before powdering can improve this condition.

2. Heat Transfer Film Quality Problem

If the powder sticking problem improves after changing to a different thermal transfer film under the same consumables and production environment, it is most likely that the thermal transfer film is of poor quality or unqualified, or the compatibility of this thermal transfer film with the ink is not good enough. Replacing the appropriate thermal transfer film can solve this problem.

3. Hot Melt Powder Problem

When the hot melt powder is wet, it will stick to the powder and become a ball shape, and there will be obvious glue edges on the edge of the pattern. At this time, the hot melt powder must be treated with moisture-proof, or the damp powder should be slightly dried and then sieved and added to the powder shaking machine.

4. Humidity Problem

Due to weather conditions, excessive humidity will cause the white ink to dry slowly, and excessive white ink will cause too much hot melt powder to stick to the edge of the pattern, forming powder edges and glue edges. The solution is to select a printer and powder shaker with a front drying system.

It should be noted that if the humidity is too high (higher than 65%), dehumidification is required to protect the machine.

5. Static Electricity Problem

If the machine is not grounded, the static electricity of the heat transfer film is high in dry weather, which can easily cause the powder sticking problem. Connecting the machine to the ground wire can improve the problem.6.Machine ProblemIf the above factors are excluded and there is still unclean hot melt powder on the heat transfer film, it may be that the quality of the powder shaking machine itself is not up to standard.

.jpg)