Understanding the Epson i3200 printhead

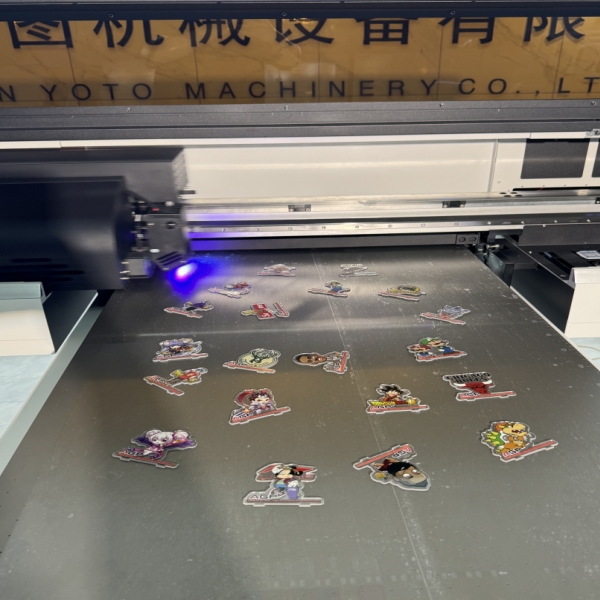

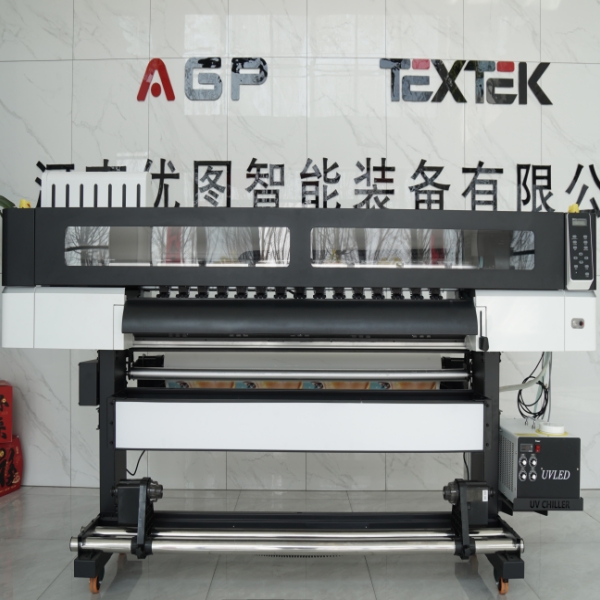

Epson printheads can be used in white ink heat transfer printers, crystal label printers, white ink heat transfer direct injection printers and other printers, and are suitable for water-based inks, UV inks and weak solvent inks. In addition, the nozzle resolution of Epson printheads is as high as 600 dpi, and one printhead can print up to 4 colors. The Epson 3200 printhead is one of the most popular printheads among manufacturers.

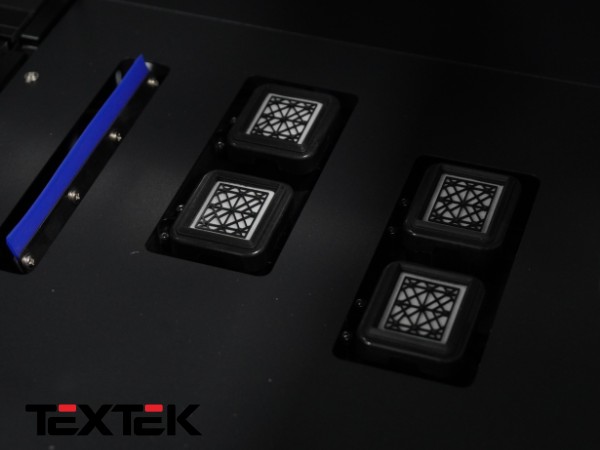

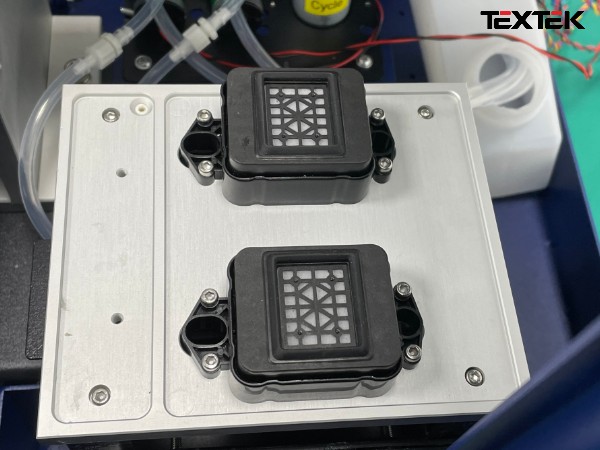

The Epson 3200 printhead is not big, with a size of about 7cm*6cm*3.5cm, but it is composed of 3200 nozzles, which can be said to be a very delicate component, so the price of the Epson 3200 printhead is not cheap. For this reason, major manufacturers must maintain the Epson 3200 printhead professionally and carefully after purchasing it.

How to maintain the Epson i3200 printhead?

1. Before shutting down the machine each day after work, move the print carriage to the left and wipe the ink stains on the nozzle surface with a special cotton cloth to keep the nozzle clean and free of debris. Later, move it back to the top of the ink pad.

2. Before shutting down the machine and after turning it on each day, you must clean the nozzle and print a test strip to check the condition of the nozzle. The test strip will show that the ink is flowing smoothly before you can shut down or start your daily printing.

If your white ink thermal transfer printer or other machine is used infrequently, you will also need to perform regular maintenance. Because from the moment the Epson nozzle is filled with ink, it needs to be kept moist and not dry. If the nozzle is not used for too long, the ink in the nozzle will dry up and clog the nozzle. Therefore, regular maintenance is very necessary.

1. Print twice a week. The print volume does not need to be too large to keep the ink in the nozzle smooth and moist to avoid drying and hardening.

2. If the nozzle is not used for a long time, you must first moisten the nozzle with moistening liquid and then turn on the machine to let the ink flow for printing.

In addition to maintaining the printhead itself, maintaining the ink pad is also very important. The ink pad and printhead are an integral part and are inseparable. The ink pad must also be kept moist at all times to seal and humidify the printhead. Therefore, manufacturers should not ignore the maintenance of the ink pad when maintaining the printhead.