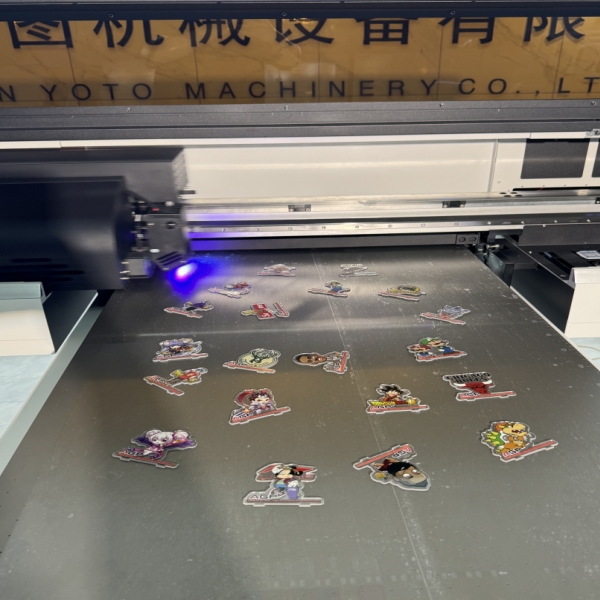

A high-quality DTF ink can print a colorful, high-saturation printed pattern that is comparable to the original image. High-quality heat transfer ink can also protect the nozzle and reduce the occurrence of malfunctions.

Inferior DTF ink will increase the defective rate, increasing the finished product of the print, and will damage the nozzle, causing the nozzle to spray ink, and increasing the maintenance cost of the printer. Therefore, we must be cautious and cautious in choosing DTF ink to reduce losses.

DTF printing ink is divided into four-color, six-color, and eight-color inks. The more inks, the better the print color and the higher the saturation. The eight-color inks are black, blue, red, blue, light red, light blue, fluorescent red, fluorescent yellow, and white. White is fixed.

We can customize different DTF ink solutions for customers for free for different color patterns. The printer ink must be selected correctly to make better products. Generally, four-color inks are enough for low-end and mid-range product patterns. If customers want to make high-end products, we generally recommend six-color and eight-color inks. After all, the more DTF printing ink colors, the brighter and fuller the printed product pattern will be.