Clothing printing processing factory – need a direct to film printer with stable performance

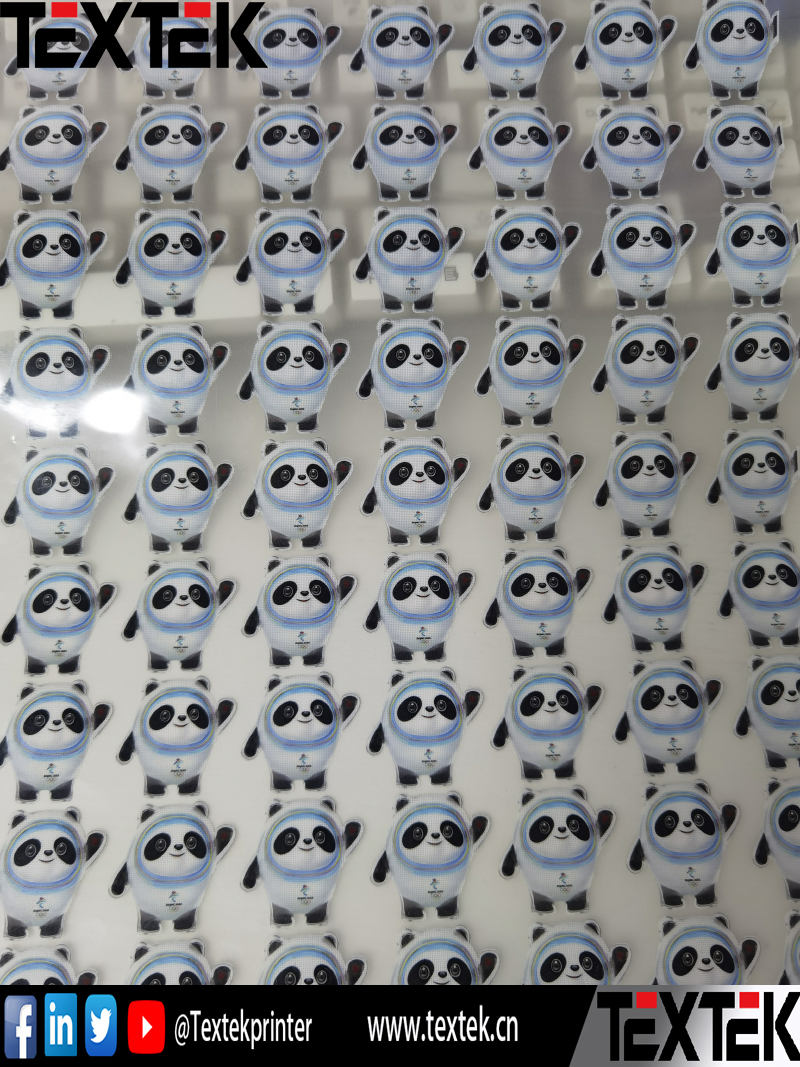

Garment printing processing manufacturers, T-shirt heat transfer printing factories, you must need a dtf transfer printer with stable performance from TEXTEK. A DTF printer with stable performance and high quality can save a certain amount of management costs for enterprises. Dtf printer is equipped with drawing software such as RIIN/Maintop/Flexiprint/Cadlink, which can change the value online and modify the details of the pattern at any time. For example, modifying the size and color of the pattern can directly improve the work efficiency of the production staff.

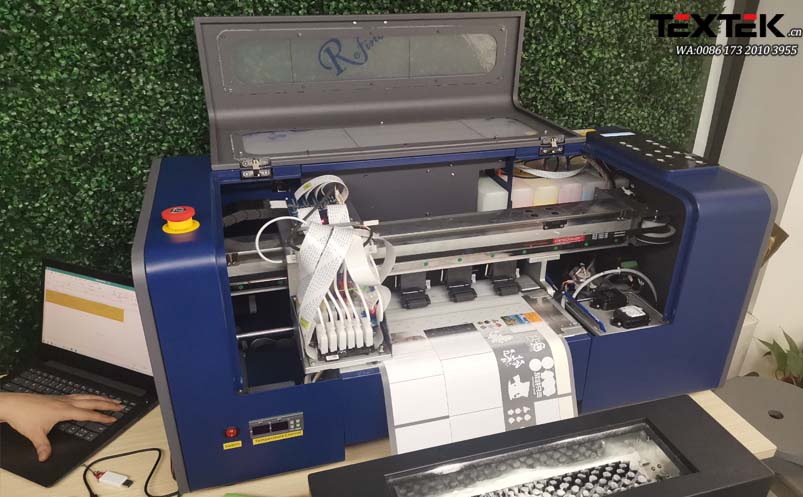

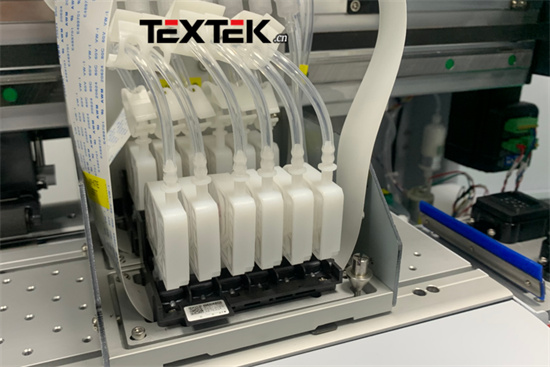

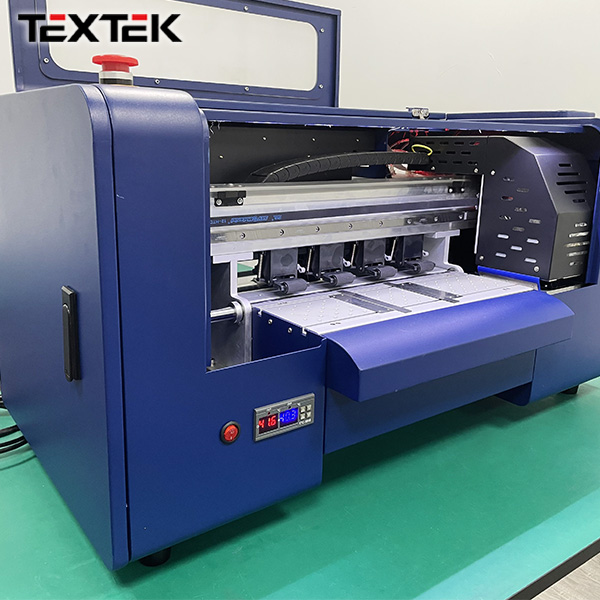

Moreover, the dtf printing machine has automatic operation function, the machine comes with automatic nozzle cleaning function, ink shortage reminder function, paper shortage alarm function, white ink automatic mixing and other functions, which are very in line with the needs of enterprise automation control products. Enterprises only need to recruit a skilled worker to operate multiple dtf printers at the same time, directly reducing the labor cost of the enterprise, which can greatly reduce the labor cost of the enterprise.

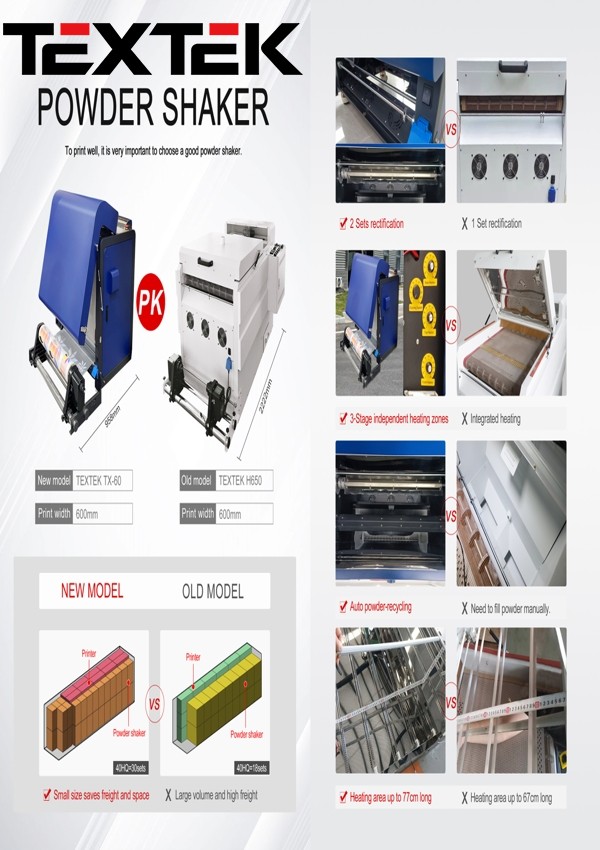

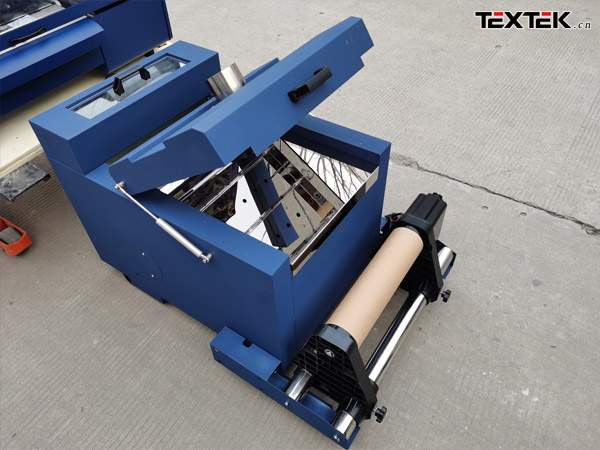

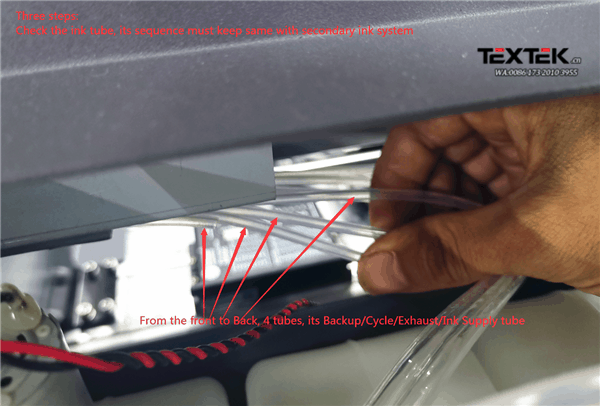

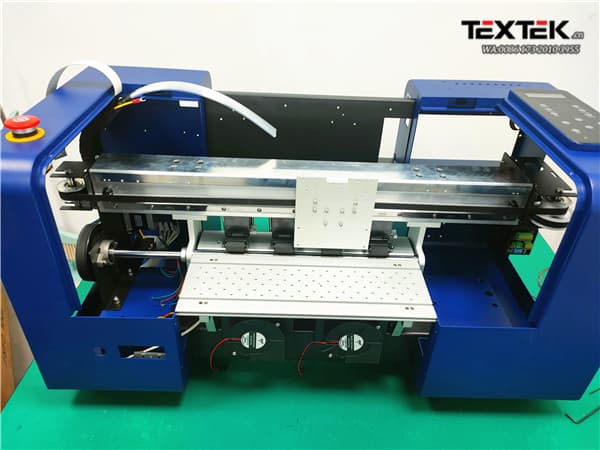

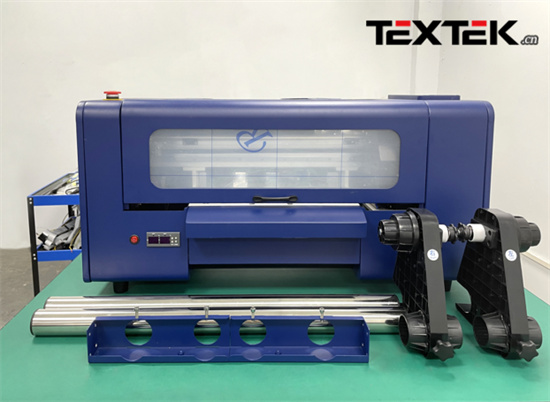

The performance of dtf shirt printing is directly related to production. The better the performance of the printing machine, the better the production. Direct transfer film printer performance includes the type and quantity of nozzles, printing width, applicable media, power, etc. These performances are also the parameters that must be understood clearly when purchasing printing equipment. Only after understanding clearly can the enterprise know whether it meets its own printing needs.

A best dtf printer with stable performance can save a lot of maintenance costs for enterprises, and the yield rate is relatively high, which not only guarantees the production but also allows enterprises to save costs. Garment printing processing factory – need a direct to film printer with stable performance.