Among the low-end customer groups in the garment printing industry, the one that can maximize the benefits is to reduce production costs. The clothing printing industry is becoming more and more fierce, which also drives the sales of dtf printers. Purchasing a high-quality TEXTEK cotton fabric printer can directly reduce printing costs. For example, good equipment is not prone to problems, which can directly reduce maintenance costs.

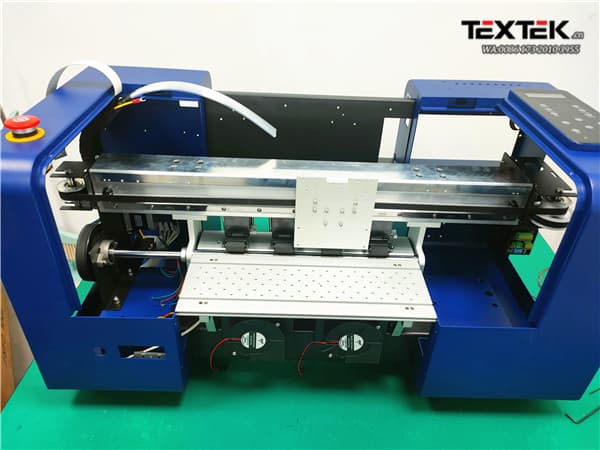

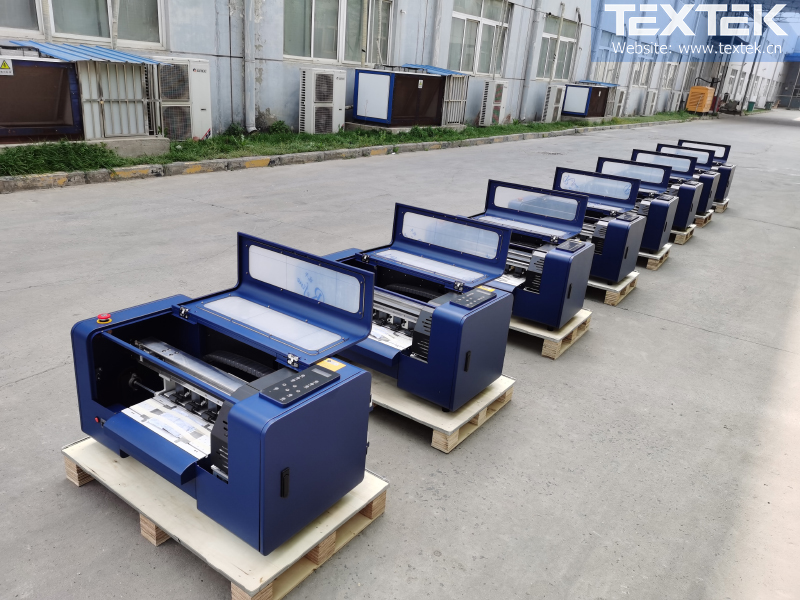

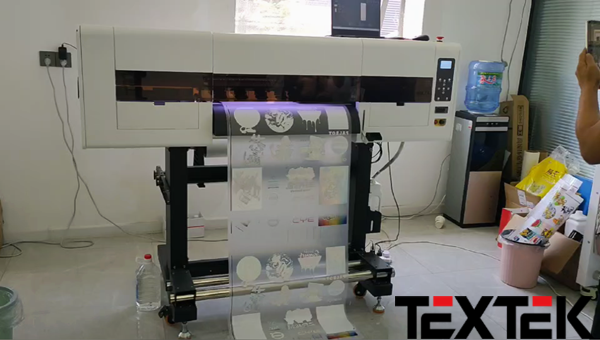

And the process of TEXTEK dtf printer is simplified, one dtf powder shaker all-in-one machine is a production line, and one person can take care of the printing work of two or three dtf printers, which greatly reduces labor costs, which also reduces production costs from the side. Epson dtf printer delivery is fast and can achieve just-in-time availability.

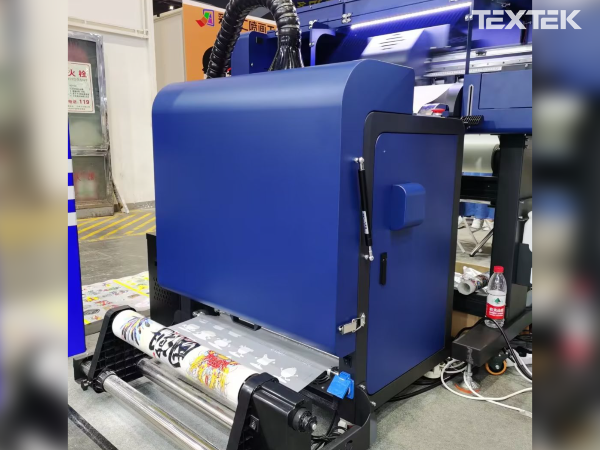

Although the share of printing in the market is limited, its potential is unlimited. In recent years, the state has been advocating environmental protection, and a large number of large and medium-sized enterprises with excessive pollution have been shut down, especially the printing and dyeing industry. TEXTEK dtf printer responds to the national call and attaches great importance to environmental protection. TEXTEK printing machine adopts green and environment-friendly materials, reduces energy consumption and working noise, and meets green production standards.

.jpg)