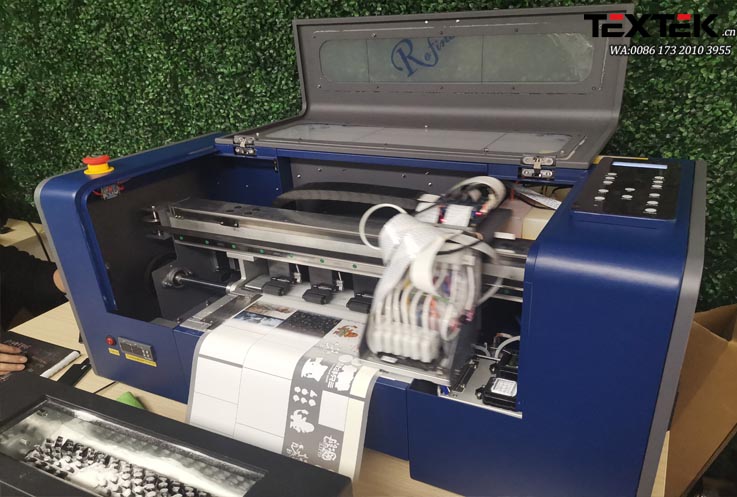

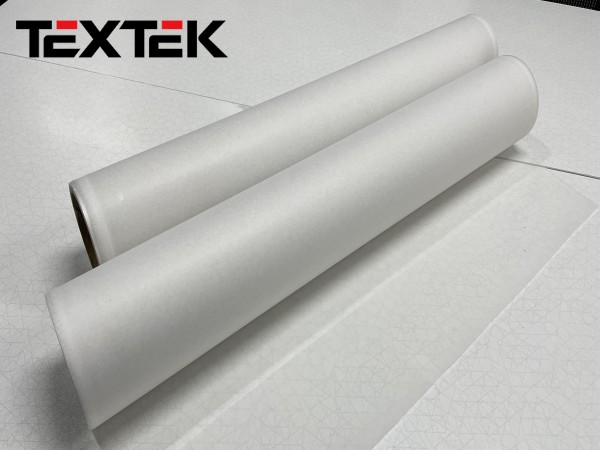

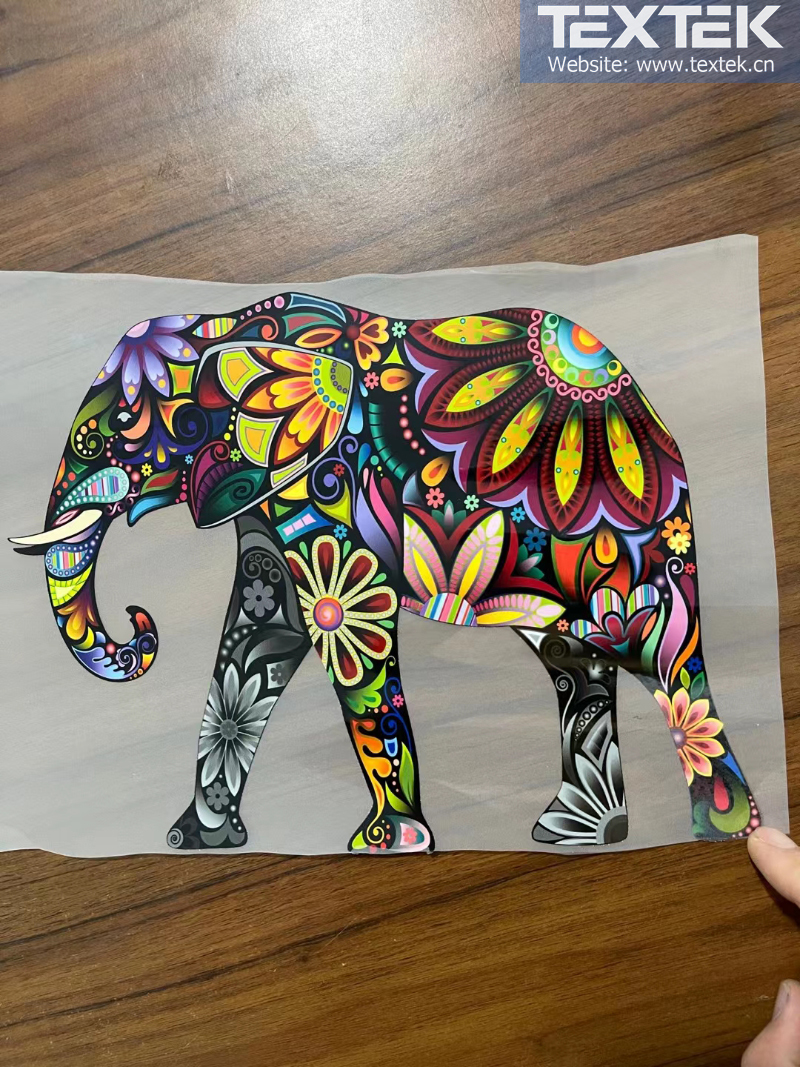

The biggest advantage of DTF Printer is that it is not limited by the batch, and it can be printed from one piece, and it will not increase the cost of a single piece because of the small batch. The complexity of the pattern is not limited, and the full-color gradient color can be printed at one time, and the machine will automatically match the color.

The printing effect is vivid and the color is bright, which can achieve photo-level precision, and the printing resolution of the machine is as high as 2880DPI. The pattern is waterproof, color fastness level 3-4, washing powder, soap, hand wash, machine wash will not fade. The pattern is UV-resistant and will not fade. The operation is simple, and anyone who can operate a simple computer can easily master it. Save labor costs. The whole process is environmentally friendly, does not produce pollution, and is harmless to the environment. Next, I will introduce the detection method of DTF Printer.

1. Maintenance of the ink tank.

Common failures of ink tanks are no ink or light writing. The reason is that the working temperature of the ink tank is high, the ink is dry, or the operator fills the ink tank with different types of ink, and the different types of ink have interactive reactions. For ink tank failure, the ink tank must be cleaned and replaced with new ink.

In addition, every time a new ink tank is installed, the print head must be cleaned. The new ink tank should not be placed in direct sunlight and dusty places. The storage temperature should be 10℃-35℃ to avoid ink freezing and changing. Because the smaller the nozzle of the inkjet printer, the higher the resolution. At the same time, the smaller the nozzle is, the higher the requirements for ink quality are. Therefore, the ink provided by the manufacturer should be used as much as possible, and the inferior ink should not be selected.

2. Maintenance of the sealing device for cleaning the print head.

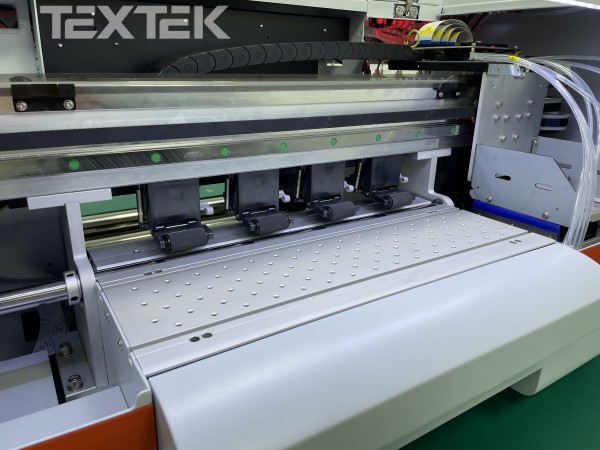

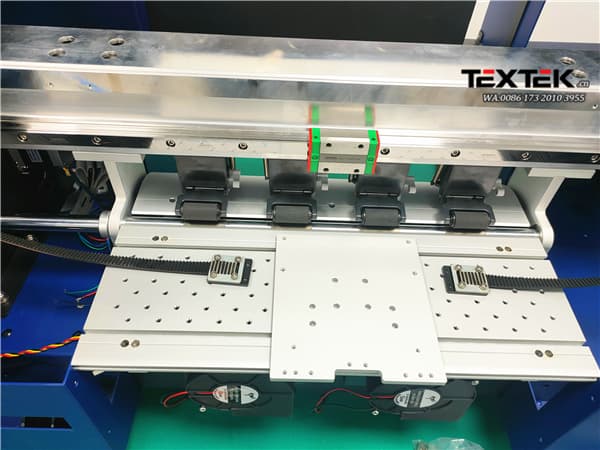

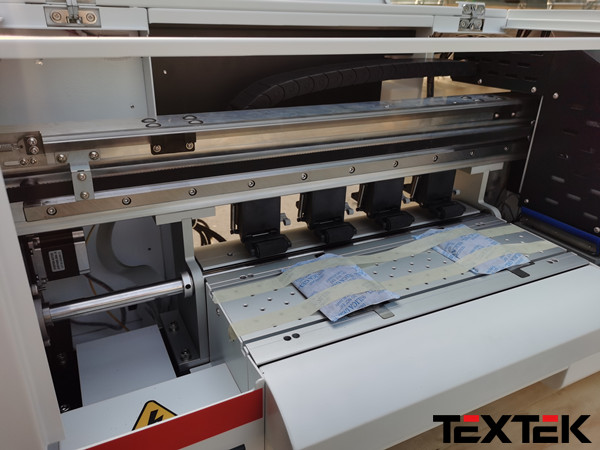

The printing head cleaning and sealing device is an important component of the printing head, especially the cleaning and sealing device for separating the printing head is more complicated. The whole device is installed at the leftmost end of the print head moving slide rail, that is, the protection position or the initial position of the print head. The device mainly completes four actions of “scraping, wiping, covering and sucking”, so as to maintain the print head and ensure its normal operation.

3. Failure of the inkjet head cleaning system.

Under normal circumstances, after the inkjet printer is turned on, the inkjet head is driven by the carriage and moves to the nozzle cleaning unit to perform the automatic nozzle cleaning procedure. The ink absorption mechanism in the inkjet head cleaning system begins to absorb ink and clean the nozzles. After that, the print head is sealed by the sealing rubber on the print head frame to ensure the cleanness of the ink jet head. When the inkjet head cleaning system fails, the printhead makes an error in the cleaning process.