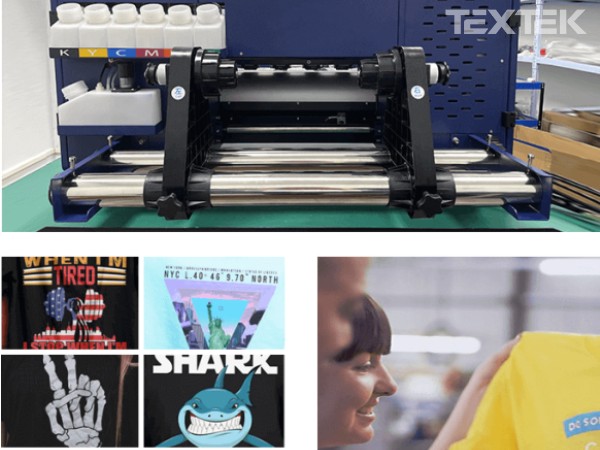

Today, when the white ink heat transfer printing process is becoming more and more popular, more and more friends have joined the heat transfer printing industry. With the increasingly fierce competition in clothing printing, how can we reduce the cost of printing products and strive for more profits? Textek manufacturers teach you how to reduce the cost of printed products.

1. Adopt high configuration computer operating system

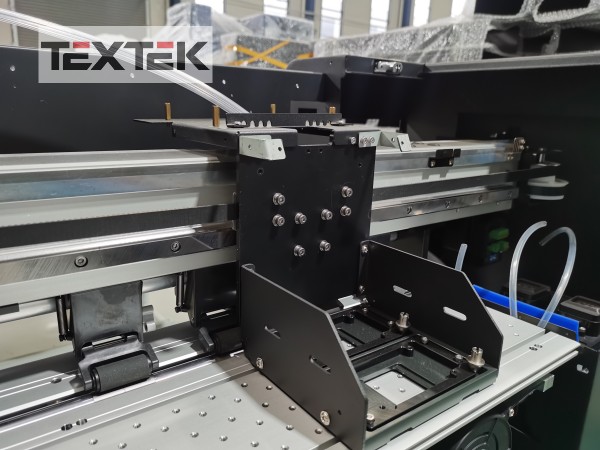

Direct to film printer is different from traditional printing. The important thing is that it must be connected to the computer. Image output and printing are realized by image processing software on the computer. Therefore, it is equipped with a highly systematic computer, which can monitor the accuracy and effect of the printing mode at any time. At the same time, genuine image processing software should be used so that the printed patterns can be better reduced in color and with better printing accuracy.

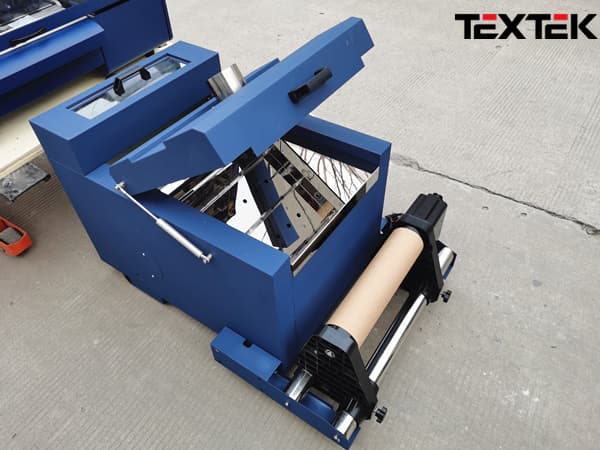

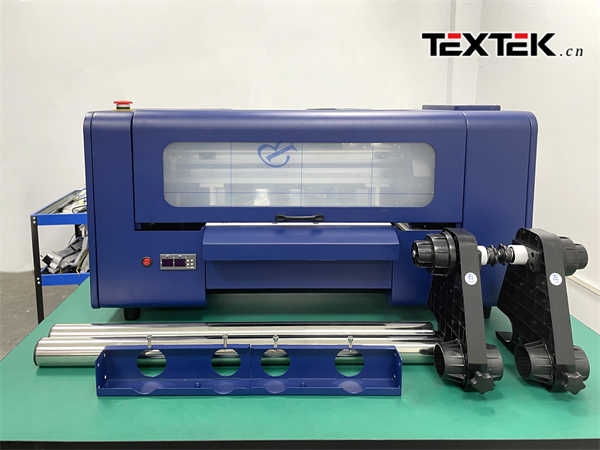

2. Purchase advanced white ink heat press equipment

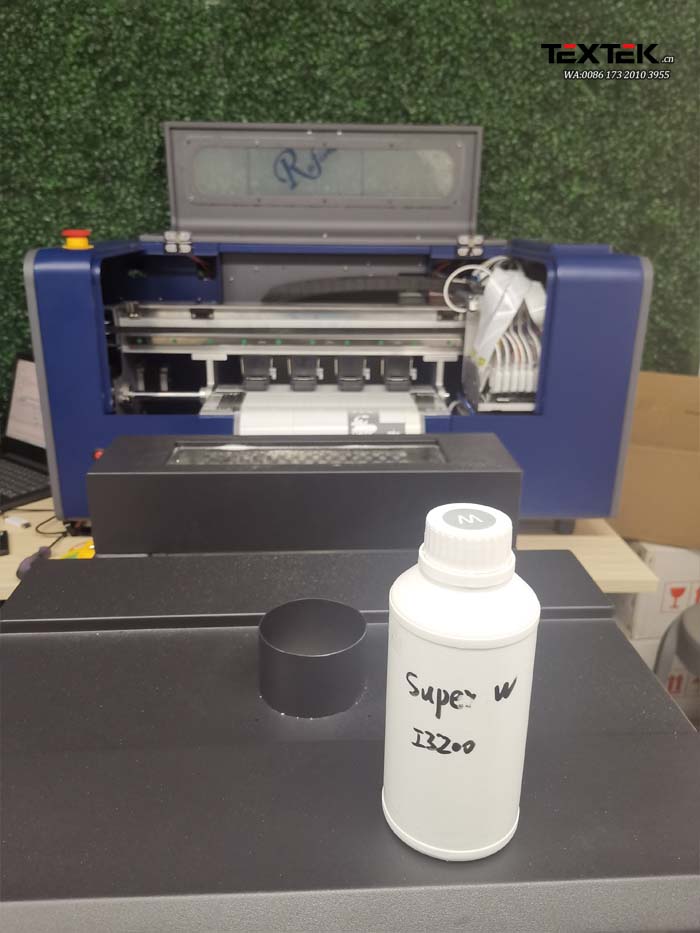

White ink heat transfer printing is produced by a white ink heat transfer machine, so it is particularly important to choose a high-quality white ink heat transfer machine. A good white ink heat transfer machine is not only reflected in the material, structure and appearance of the machine, but also in the performance of the core configuration. Different grades of white ink heat transfer machines have different printing effects, speeds and performance stability.

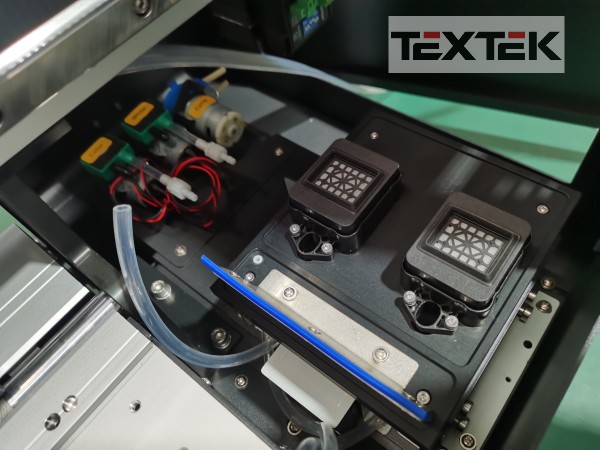

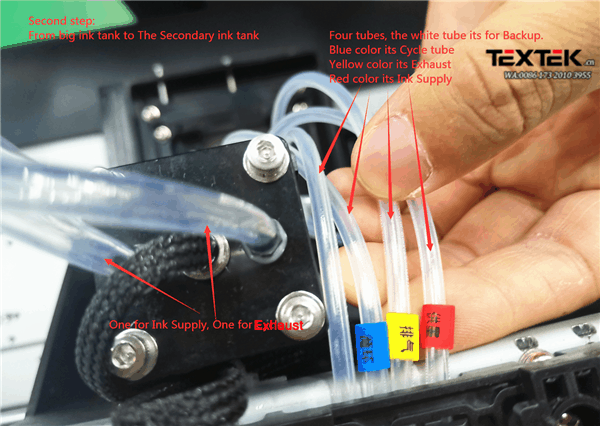

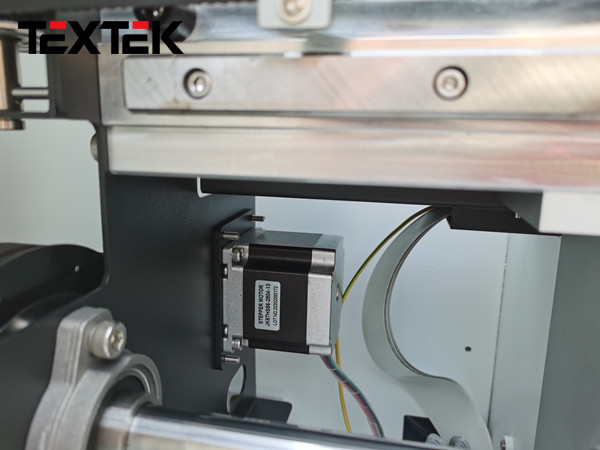

3, usually do a good job in the maintenance and maintenance of the white ink heat press machine

Like people, machines and equipment also need to rest after a long period of high-load operation, and use some products to maintain them when necessary, so that they can be used for a longer period of time. The white ink heat press machine is the same, especially the nozzle of the white ink heat press machine, its service life is limited, the price is not low, and it needs to be well maintained and maintained. For example, regularly clean the ink path and ink stack to prevent ink jetting, ink leakage and clogging. Generally speaking, the ink stack needs to be replaced every three months to improve the life of the print head. White ink heat press machine slides, platforms and trolleys should also be checked regularly and kept clean at all times.