What’s the matter with the DTF Printer nozzles often clogged with ink?

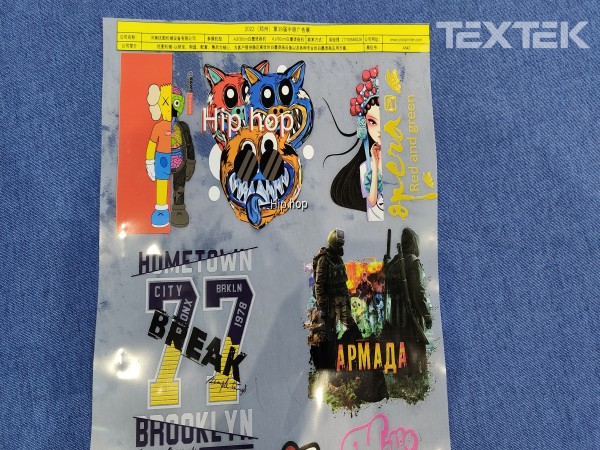

Occasionally, some customers and friends give us feedback as to why the nozzles of his white ink heat transfer printer often have ink blockage. The problem can be solved after each ink blockage is cleaned once or twice, but the ink will be blocked repeatedly, and I don’t know how to solve it. Today, I will explain to you why white ink heat transfer printers often experience ink blockage.

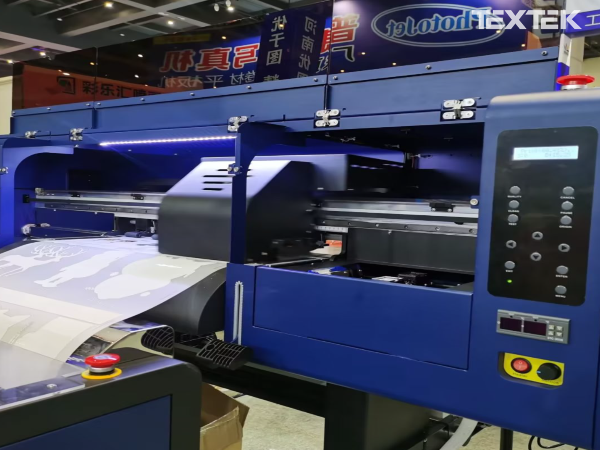

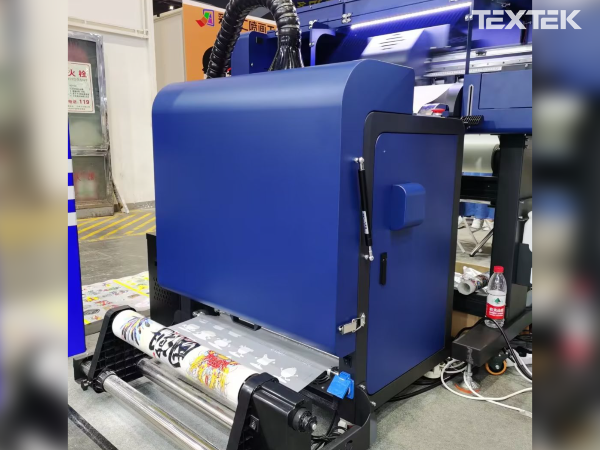

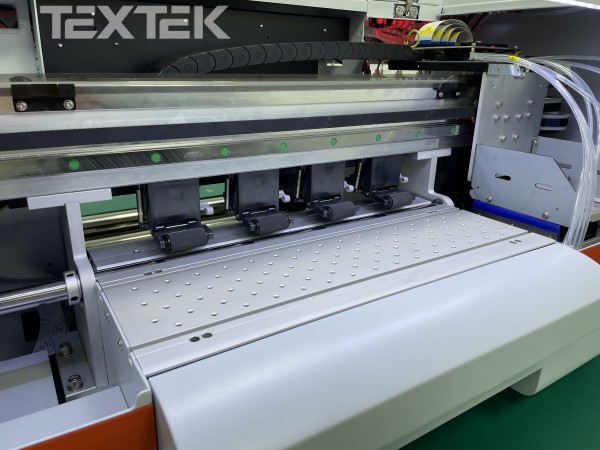

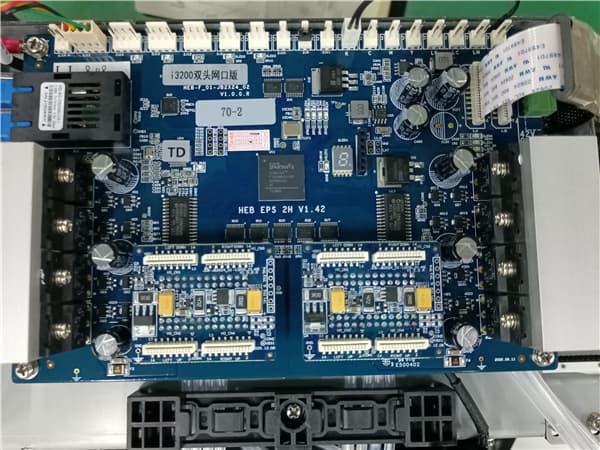

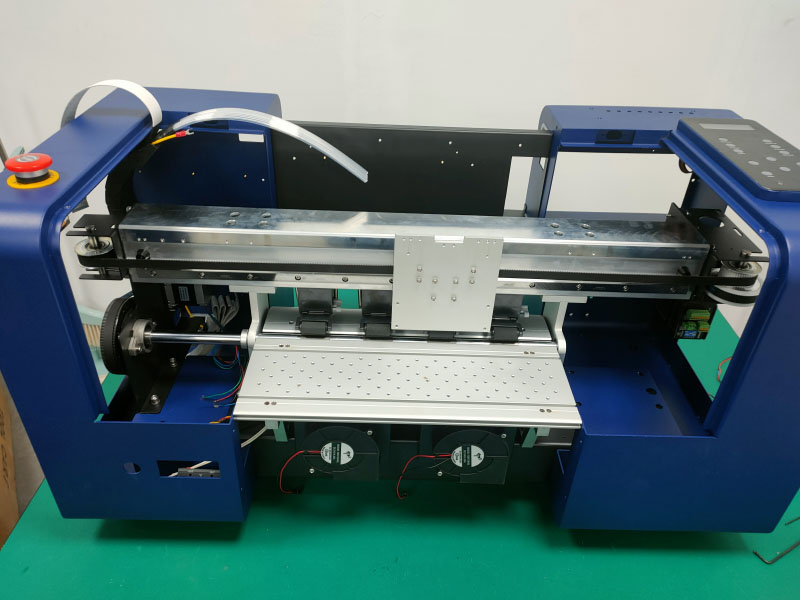

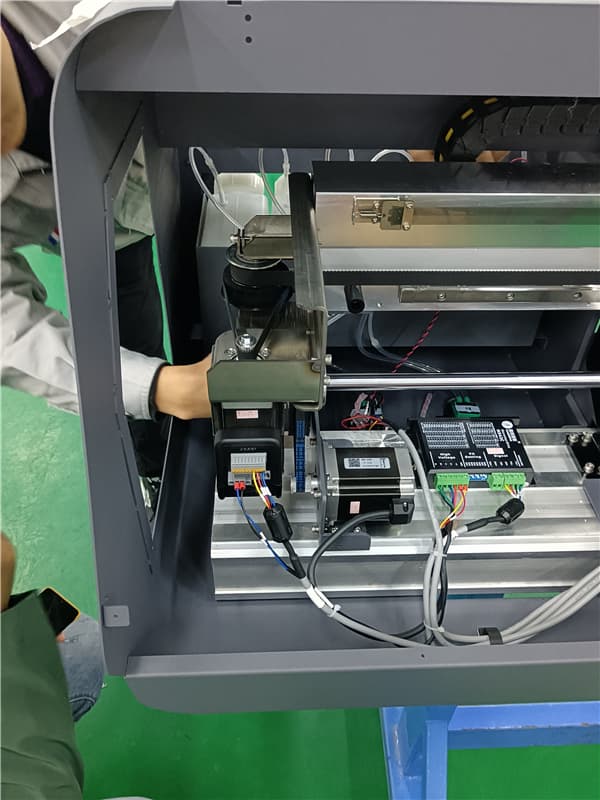

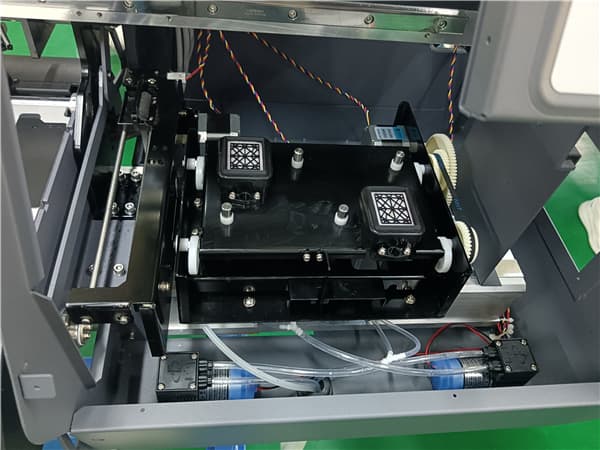

Generally, the ink blockage can be solved by using the nozzle cleaning function of the printer to clean it once or twice. This phenomenon is a slight ink blockage. Generally, the slight ink blockage occurs because there is a lot of dust around the heat transfer printer, or the ink is not smooth enough, or it may be due to other reasons. We all know that TEXTEK uses Epson’s 3200/4720 nozzles. Epson’s nozzles are very accurate. The size of the nozzle holes cannot be seen with the naked eye. Only with a magnifying glass can the situation of each nozzle hole be clearly seen, so it is very slight. lint or dust can cause slight clogging of the print head.

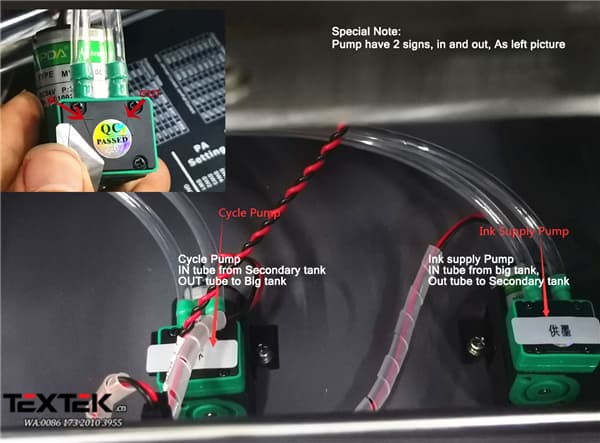

How to solve the problem of ink blockage in the nozzle of white ink heat transfer printer? Before turning on the machine every day, observe whether there are deposits on and around the white ink heat transfer printing machine. To improve the environmental sanitation around the natural environment of the equipment, check the supply of ink every day. When the ink is about to bottom out, you need to replace the ink immediately to prevent the gas from being drawn into the ink tube. When in standby, the nozzle of the white ink heat transfer printing machine should be controlled to the original position, and the nozzle will be sealed by the protective cover in the original position, so that the nozzle is not easy to be blocked, and the service life of the nozzle and the equipment is ensured.