DTF is a process used in the clothing industry. That is to say, it is transferred to the fabric at high temperature. The required pattern is designed on the computer and sent to the DTF printer for printing. Then it is dusted with powder by a powder shaker and baked at high temperature to fix the color. It can be pressed and ironed onto clothes without the need for pattern making, engraving, waste disposal, and there is no minimum order quantity.

The following is the DTF process flow chart provided by TEXTEK:

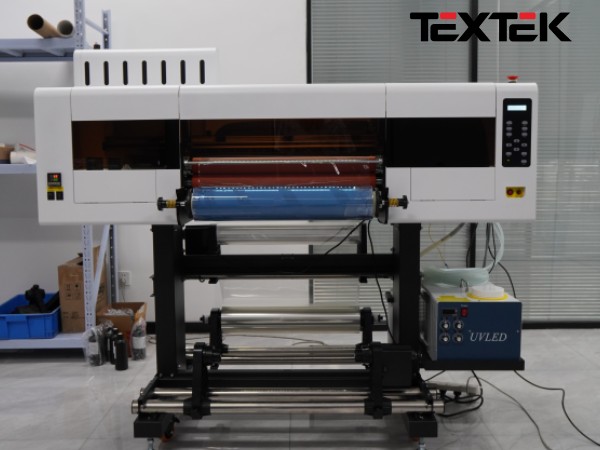

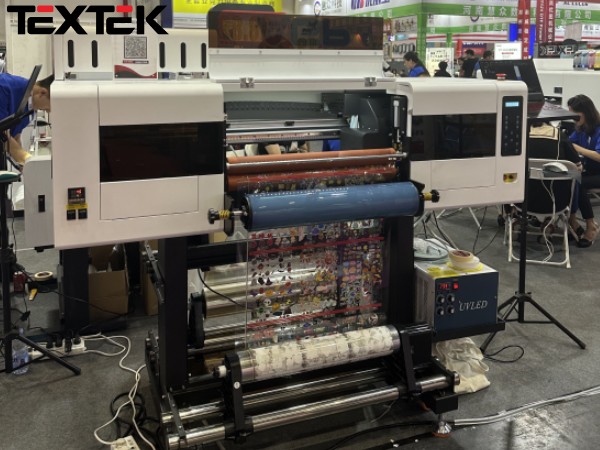

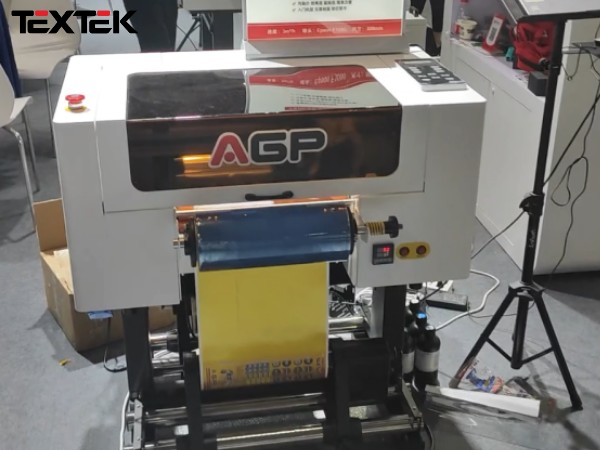

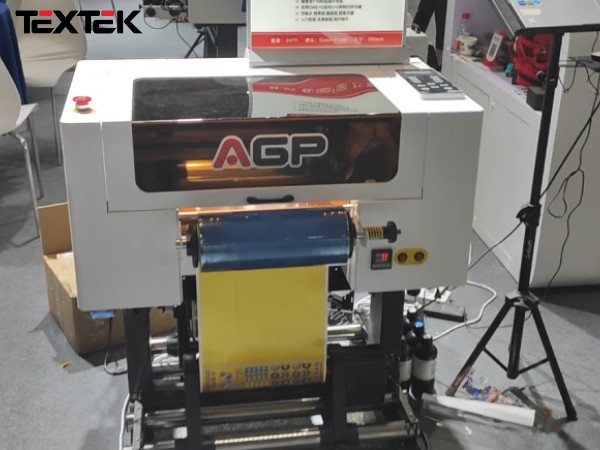

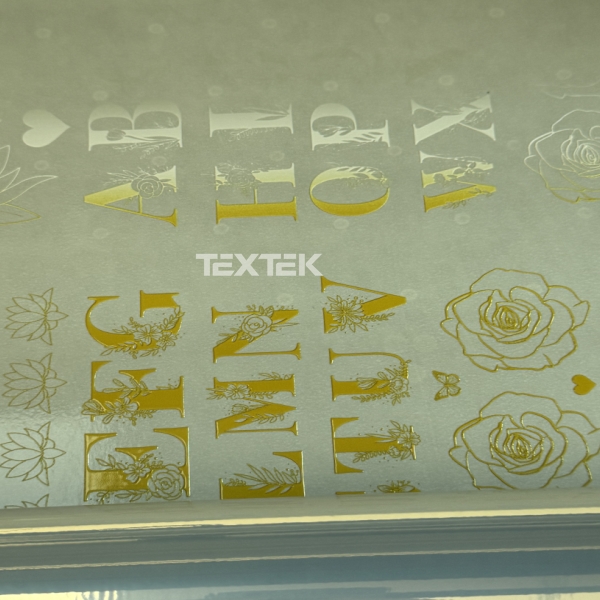

UV DTF is a new process used in the advertising industry. It is different from DTF in that the process is simpler. Design the required pattern on the computer and transfer it to the UV DTF printer for printing. After printing, it will be automatically laminated and can be used directly. Compared with DTF, there is no powder shaking machine in the hardware. There is no need for high-temperature fixation. You can just stick it on the required items by hand or machine. The effect is very bright and bright, and has a protruding three-dimensional effect. No minimum order is required. quantity to achieve a true minimum order quantity of one piece.

The application differences between DTF and UV DTF:

DTF is mainly used in fabrics, and some of them are made of cotton or polyester. The most common ones are T-shirts and sweatshirts. There are also reusable bags, pillows, aprons, advertising shirts and cultural shirts, as well as linen, denim, and press.

UV DTF is mainly used on hard objects, such as glass, metal, acrylic, wooden boards, ceramics, plastics, cardboard cases, etc. It can be pasted on flat or curved objects. Typical representatives are tea boxes, Wine bottles, cosmetics, logos and other applications.

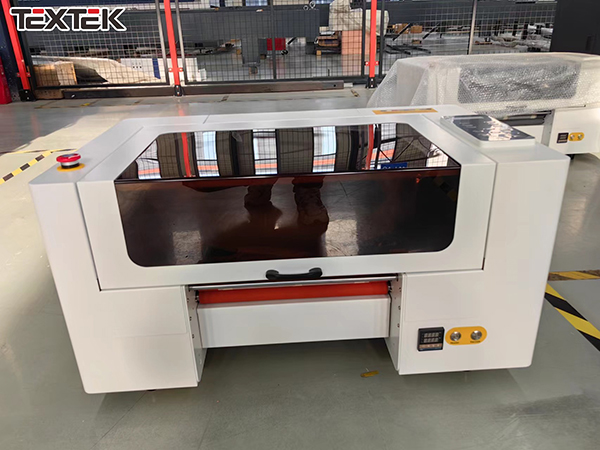

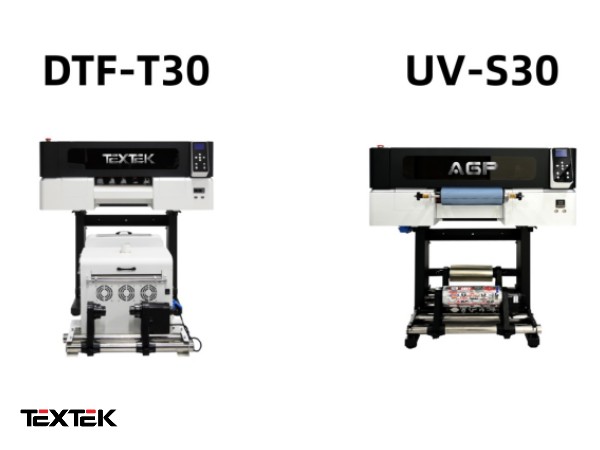

The hardware machine differences between DTF and UV DTF:

DTF requires a combination of a printer and a powder shaker, while UV DTF only requires a UV DTF printer and no powder shaker.

The difference between ink between DTF and UV DTF:

DTF uses water-based ink, while UV DTF uses oil-based UV ink, so there are UV purple lights on both sides of the UV DTF printing car, which can be irradiated while printing to fix the color.

The difference between DTF and UV DTF printing films:

There is only one type of DTF printing film, but the printing film can be single-sided or double-sided, or cold-tearable or hot-tearable, depending on the different needs of the customer.

The UV DTF printing film can be used in combination of A film and B film. Film A is a printing film and comes with its own glue. The glue layer is also an ink-absorbing layer. After printing, film B is automatically coated. Film B is a transfer film. Go to B film plays the role of protection and reposting, which is automatically completed by UV DTF, and no manual coating is required in the process.

.jpg)