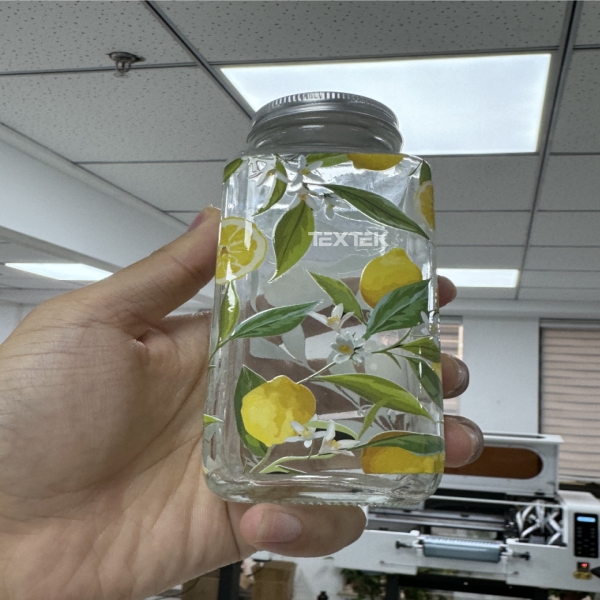

Do you know UV Varnish?

UV varnish is a transparent coating, its role is to spray or roll coating on the surface of the substrate after the UV lamp irradiation, so that it is converted from liquid to solid, and then to achieve the surface hardening, its scratch-resistant and scratch-resistant role, and the surface looks bright, beautiful, rounded texture. The following TEXTEK for you to introduce the UV varnish common problems and solutions, storage environment.

1. Bad drying, incomplete light curing, sticky surface

Main reasons:

1. The intensity of ultraviolet light is not enough;

2. The UV lamp ages and its intensity weakens;

3. UV varnish is stored for too long;

4. Too much diluent that does not participate in the reaction is added;

5. The printing speed of the machine is too fast.

Solution: When the curing speed is required to be less than 0.5s, it must be ensured that the power of the LED curing lamp is generally not less than 120W/cm, and the lamp tube (bead) must be updated in time, and do not wait for it to break before replacing it.

2. Poor gloss and insufficient brightness

Main reasons:

1. The viscosity of UV varnish is too small and the coating is too thin;

2. Excessive dilution with non-reactive solvents such as ethanol;

3. The UV varnish is unevenly applied.

Solution: Increase the viscosity and amount of UV varnish appropriately according to the different conditions of the material.

3. UV varnish thickens and gels

Main reasons:

1. UV varnish is stored for too long;

2. The varnish cannot be stored completely away from light;

3. The storage temperature is too high;

Solution: Pay attention to the effective use period of UV varnish and store it strictly away from light. The storage temperature is 5℃~25℃.

4. The UV varnish on the surface of the printed matter cannot be applied or becomes stained

Main reasons:

1. The viscosity of UV varnish is low and the coating is too thin;

2. The ink contains too much adjusting oil or drying oil;

3. The ink surface has crystallized.

Solution: When printing products that require UV glazing, apply a thicker layer of UV varnish. If necessary, the problem can be solved by replacing special varnish.

5. UV varnish has white spots and pinholes

Main reasons:

1. The coating is too thin;

2. Too much non-reactive diluent (such as ethanol) is added;

3. There is a lot of dust on the surface of the printed matter.

Solution: The production environment and printed surface should be kept clean and the coating thickness should be increased.

6. UV varnish has poor adhesion

Main reasons:

1. Printing ink surface crystallization;

2. The auxiliary materials in printing ink are not suitable;

3. The UV varnish itself has insufficient adhesion;

4. The light curing conditions are not suitable.

Solution: The printing process should consider the glazing oil conditions in advance.

7. The surface is unevenly applied and there are streaks

Main reasons:

1. The viscosity of UV varnish is too high;

2. The application is too thick and not smooth;

3. The amount of application is too large;

4. UV varnish has poor leveling properties.

Solution: Reduce the viscosity of UV varnish and reduce the amount of application.