What is the difference between UV transfer stickers and lettering stickers?

Lettering Sticker

Lettering sticker is a composite material made of paper, film or special material, with adhesive on the back and silicon-coated protective paper as the base paper.

Due to the variety of coating techniques, resulting in different grades of instant stickers, the current development direction is from the traditional roll coating, doctor blade coating to the direction of high-pressure cast coating, so as to ensure the uniformity of coating to the greatest extent. Sensitivity, to avoid the generation of bubbles and pinholes, to ensure the coating quality, while the domestic technology of cast cloth coating is not yet mature, and the traditional roll coating is mainly used in China.

Lettering stickers are only suitable for some thick-lined font designs because they need to manually remove the redundant parts. Too small places cannot be made by hand and are not easy to transfer.

Lettering stickers are generally pasted on glass, or where the surface is flat and smooth and easy to paste. It has a warning function. When encountering large-sized lettering stickers, it is not good to paste them without a few years of experience. Here I will share with you how to paste them:

1) First select the position where the sticker is to be pasted, and then wipe off the dust or oil stains on the place to be pasted;

2) Hold the stickers and make gestures to see how to stick them best;

3) Because it is usually pasted on the glass, it is recommended to spray some water on the glass and the sticker before pasting it, and finally adjust the position and scrape the water with a scraper;

4) Paste the transfer film on the engraved words, stick the words together, and then paste them on the glass. Do not paste them all at once;

5) If there are air bubbles after pasting, prick it with a needle, and then paste it flat with a rag.

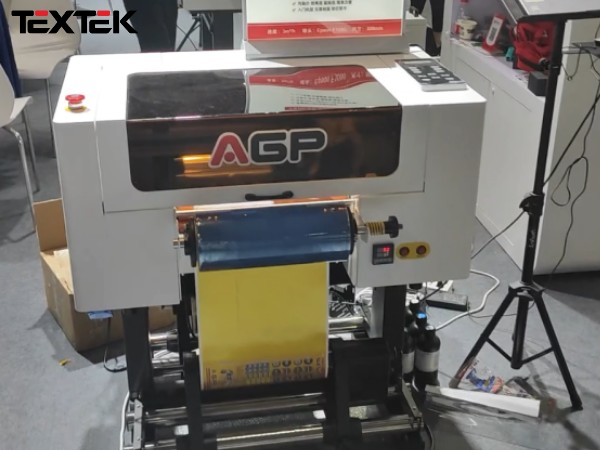

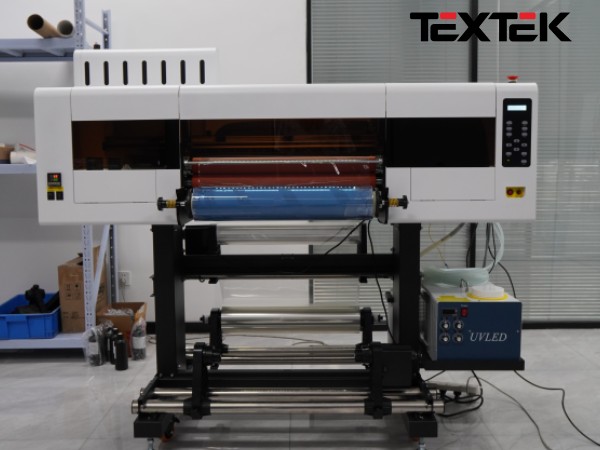

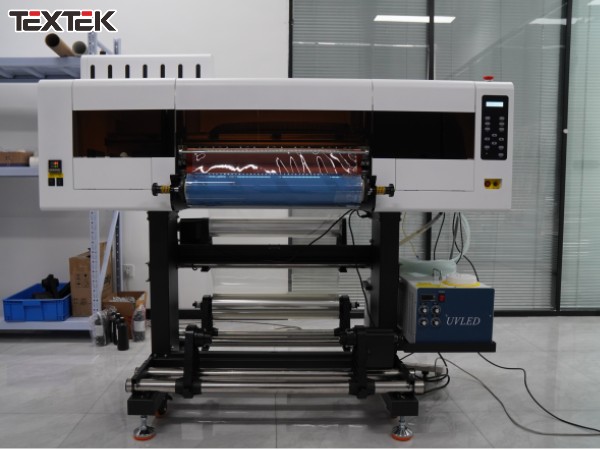

UV Transfer Sticker

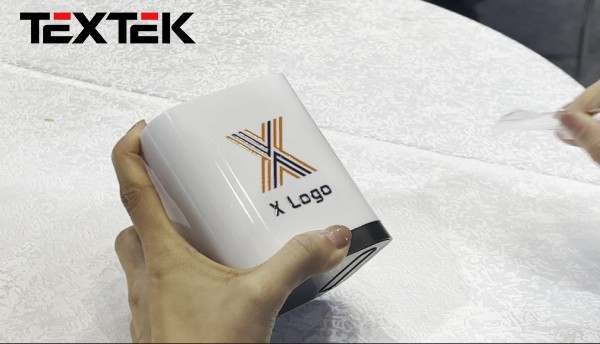

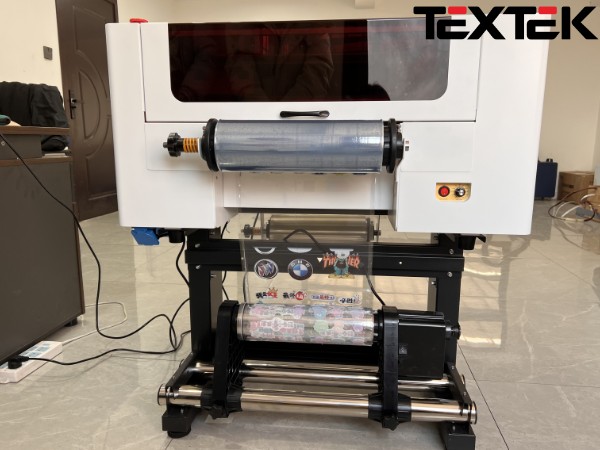

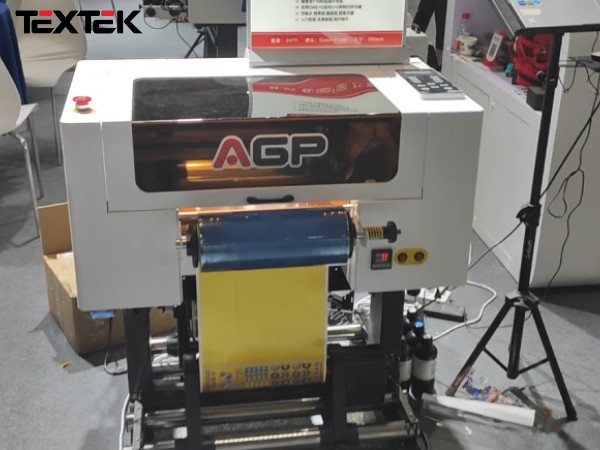

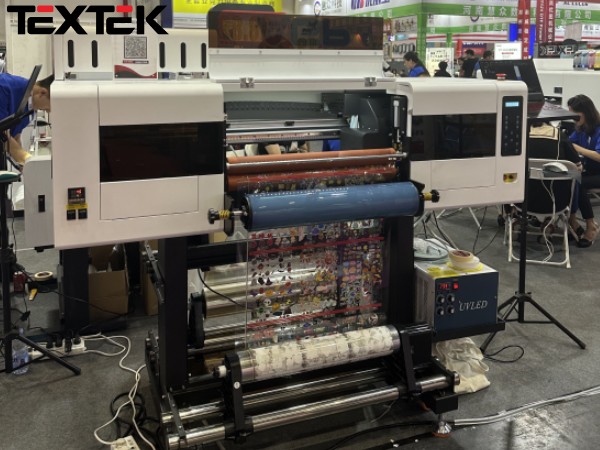

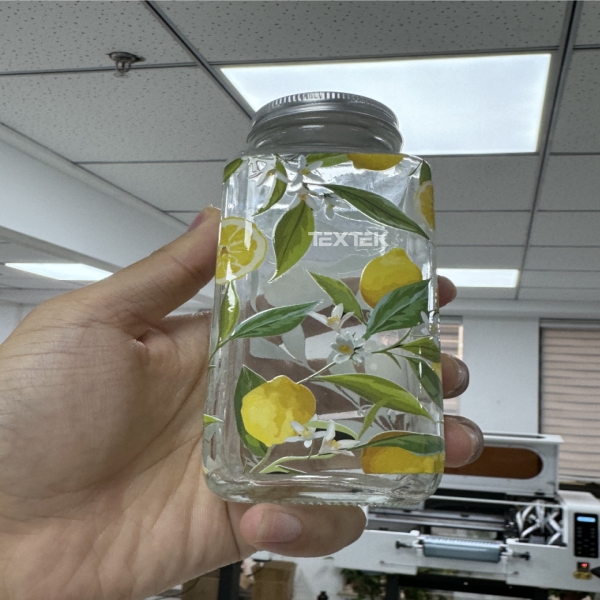

UV transfer stickers, also called crystal labels, are first printed with glue, isolation, patterns, bronzing, and varnish layer by layer on special PP release paper to form patterns, trademarks, etc., and then cover the transfer film. Then use the transfer film to transfer the pattern to the surface of the object.

UV pressure-sensitive stickers are mainly used in: packaging boxes (gift boxes, tea boxes), plastics, metals, electrical appliances, sports equipment (helmets, bicycle frames, etc.), carbon fiber (fishing rods, rackets), wood (holding ball sticks, furniture) , handicrafts) and other irregular surface decoration.

Pasting method: After the product is formed, tear off the graphics and transfer film from the release backing paper, and then align the pattern with the transferred position and paste it on. After lightly rubbing the surface of the sticker with your hands, tear off the transfer film on the surface to complete the transfer.

Finally, I would like to emphasize the usage skills: both stickers are pasted by transfer printing, so you must be careful when pasting them. If the lettering sticker is not easy to transfer, we can reverse it and tear it out slowly. When pasting, press it well and then tear it out slowly. The main thing about UV transfer printing is that you must press it well and then tear it out slowly. Avoid tearing the stickers.