Digital printing is popular, and the short Construction period of dtf printer helps fast fashion

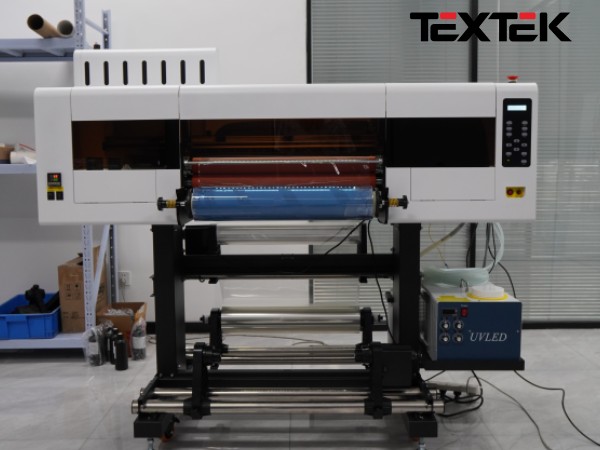

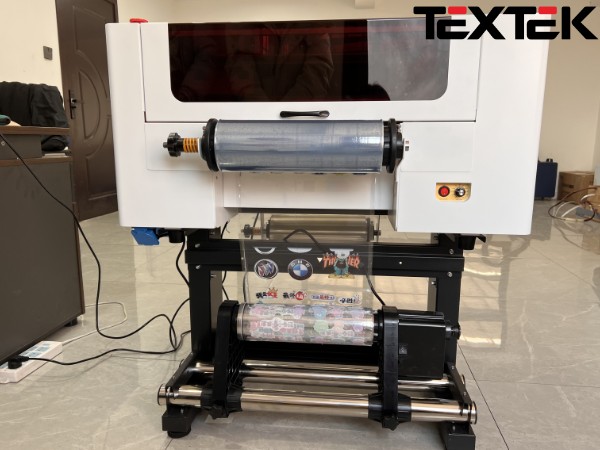

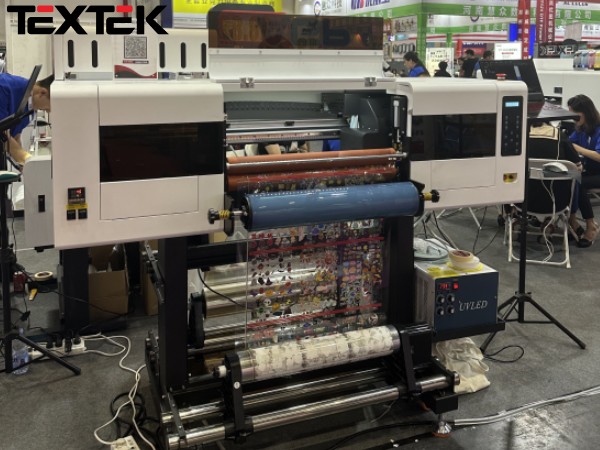

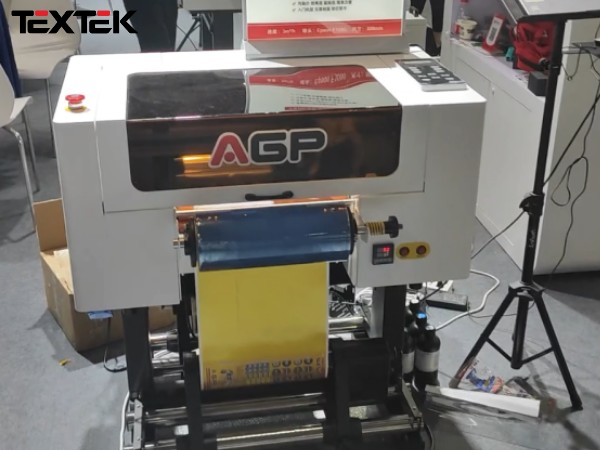

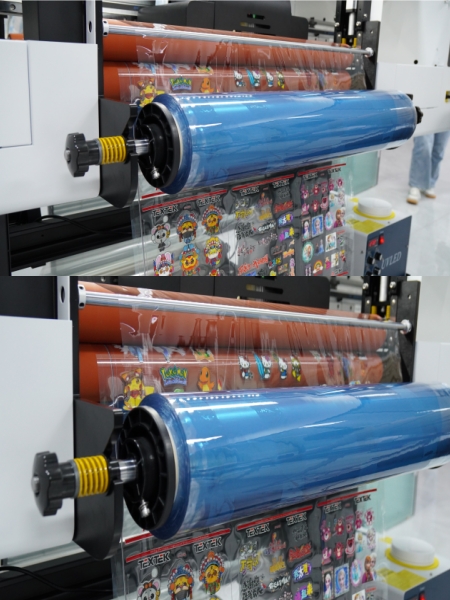

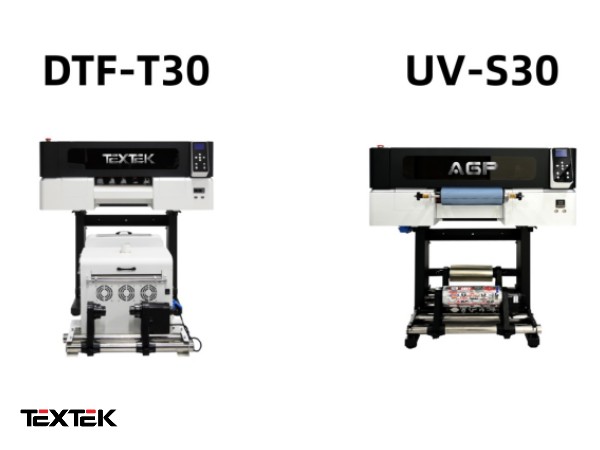

In the past two years, the digital direct to film printer with two nozzles has been popular in the digital printing market. It has subverted the application process of the traditional printing industry with the advantages of one-key hollowing out and no need for typesetting. 2 head, 3 head and 4 head dtf printer, so why is the dtf printing machine so popular?

Clothing is inseparable from printing, especially with the hot development of personalized customization, unique printing has become a magic weapon for clothing brands to occupy more market share, and relying on the vigorous development of e-commerce, the clothing personalized customization industry is gradually promoting to standardization and intelligence, the market caliber is also expanding. With the vigorous development of fast fashion at home and abroad, only by maximizing the flow and supply chain at the same time and shortening the production cycle can we seize the market!

In the early years, printing basically used the screen printing process. Screen printing is mostly manual operation, and there are many printing processes. During the operation, the technique and proficiency of paint color paste and scraping ink are relatively particular. The quality of color paste and the priority of the technique will affect the final product effect. In addition to the defects of cumbersome process, high labor cost and long construction period, the biggest problem of screen printing is that it will pollute the environment, which is undoubtedly fatal to the modern society with higher and higher environmental protection requirements.

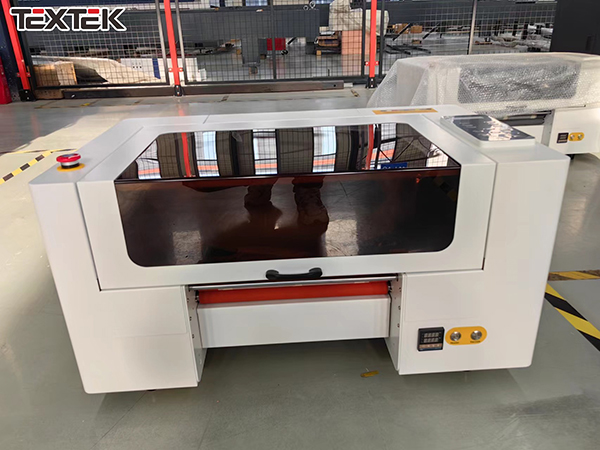

The garment industry needs to find a new process to replace it, and digital printing dtf printer has become a better choice at the moment. Digital printing, printing with digital technology. With the continuous development of computer technology, it is a high-tech product that integrates machinery, computer, electronic and information technology. The emergence and continuous improvement of this technology has brought a new concept to the clothing customization industry, and advanced production principles and methods have brought an unprecedented development opportunity to the clothing customization industry.

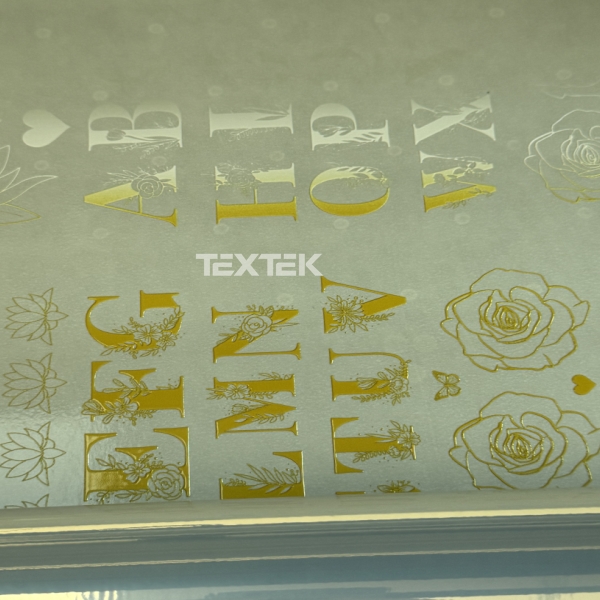

The pattern made by the digital printing process has a wide color gamut, bright colors, high precision, delicate images, and soft hand feeling. Its principle makes the product break through the traditional production of color registration and flower back length restrictions, and can make textile fabrics achieve high-end printing. The printing effect has broken through the color registration limit of traditional textile printing and dyeing patterns, especially in the printing of high-precision patterns such as color gradients and moires. Digital printing has incomparable advantages in technology, pure machine operation, High production efficiency, suitable for mass production. Digital printing also has the following advantages:

1. Quick version printing: the drawing can be published after adjustment, no need to print out the film and print the screen version.

2. Space-saving: small footprint, and multiple machines can be placed in a small space.

3. Labor saving: one person can watch multiple machines, and save complex processes such as net pulling, plate making, plate printing, pulp mixing, plate feeding, cloth spreading and receiving.

4. Simple operation: you only need to understand a little computer to operate, call people at any time in peak season, no need to be restricted by professional printing workers.

5. One-piece printing: one piece can be printed, suitable for small-batch online orders and personalized customization.

6. Bright colors: the color saturation is high, the solid color is pure enough, and the pattern is delicate and realistic.

7. Wide range of applications: printing factories, garment factories, personalized customization, online order sales and other craft factories can be used. The products can be applied to clothes, pants, hats, bags, home textiles, etc., with strong adaptability.

8. Environmental protection: Waterless, odorless, smoke-free and dust-free production process, non-polluting, green and environmentally friendly, in line with national environmental protection requirements.