A new hotspot in the processing industry and UV printer industry:

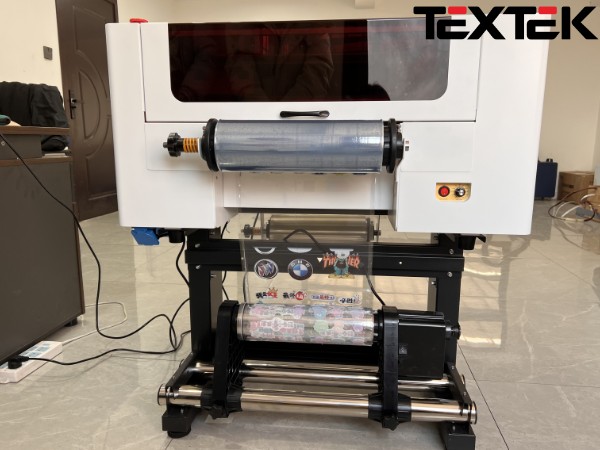

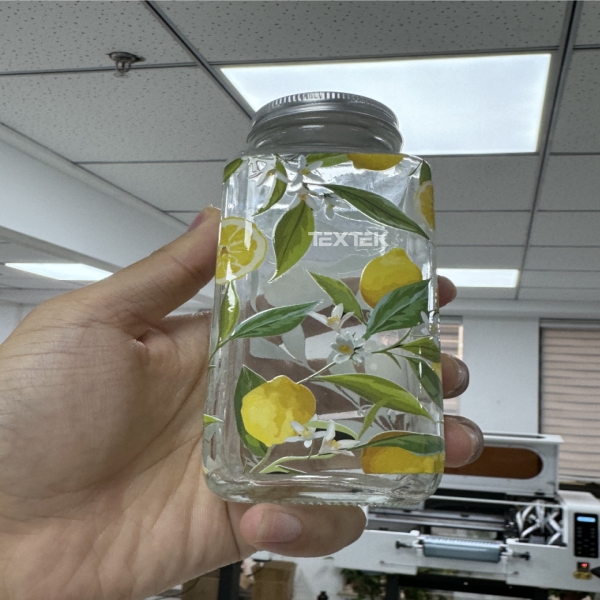

Crystal sticker! ! Crystal sticker is also called UV transfer sticker. Its predecessor is called pressure sensitive sticker. It is printed on the special release material with the required graphics and text, and then covered with transfer film, and then uses the film to transfer the pattern to the surface of the final product. A surface graphic production process.

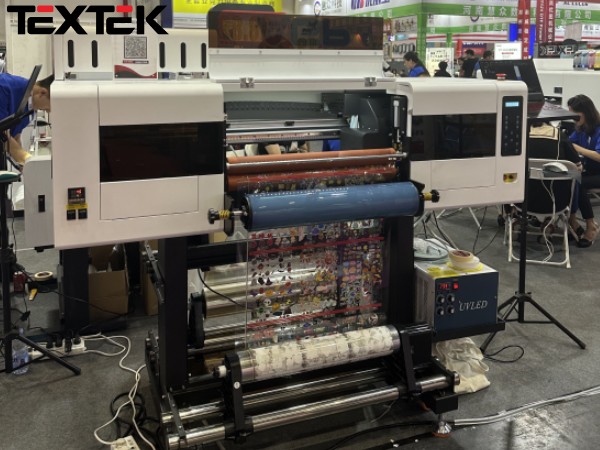

At present, there are four mainstream production processes in the market: pure screen printing, screen printing + digital, AB film digital solution, and digital spray glue solution. UV printers can also be used for pattern printing of crystal labels. When it comes to crystal labels, its feature is that it can be made in small batches or even one piece, and the pictures and texts can be left on the tear film.

In addition to good pattern effects, it also has good scratch resistance, wear resistance, and weather resistance. This is somewhat similar to the advantages of UV printers.. At present, crystal labels are mainly used in packaging, marking, and special-shaped and irregular surfaces with poor printing efficiency using UV printers, such as products with cylindrical surfaces. The difficulty of the crystal label is not the equipment, but the stable process.

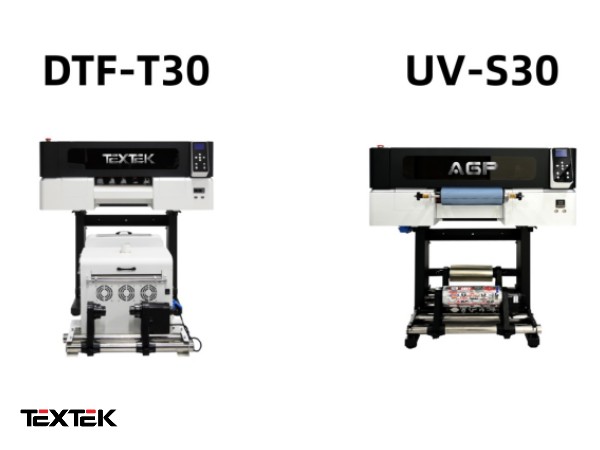

However, using uv dtf printer to make crystal logo graphics has obvious advantages in terms of labor, environmental protection, and personalization compared with silk screen printing and transfer printing.

.jpg)