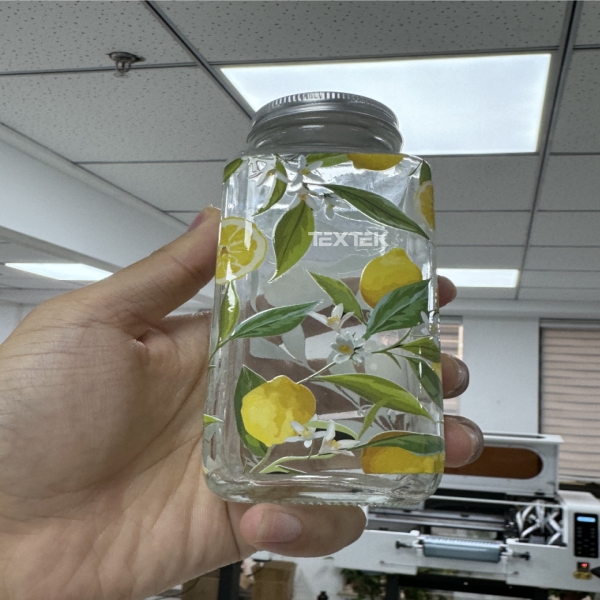

The advertising application solution in 2021 has to be the crystal logo. Because it does not choose the shape or material, it can be called a personalized customization artifact and is deeply loved by advertisers. Crystal label printers have also become a hot-selling equipment that is hard to find, mainly because the crystal label market has a broad market prospect and a wide range of applications. It can be used in applications that stickers can do, and it can still be used in applications that stickers cannot. , relying on its strong advantages to dominate the advertising application field, has won the favor of many merchants and consumers.

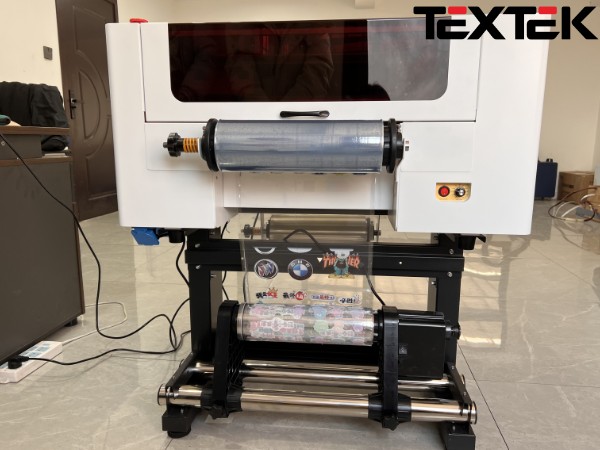

Product details are visible

Precise hemming

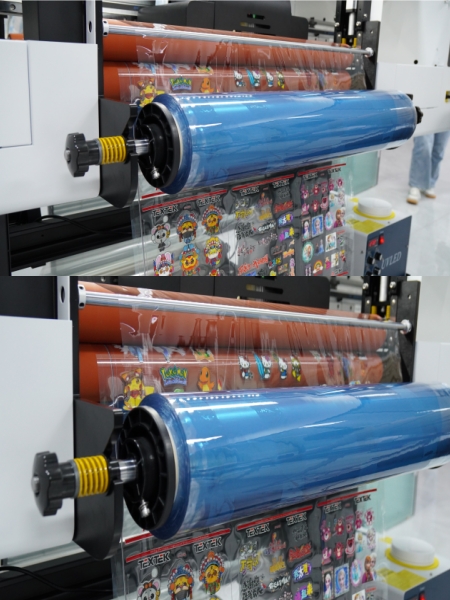

The AB film is even and smooth, with precise positioning

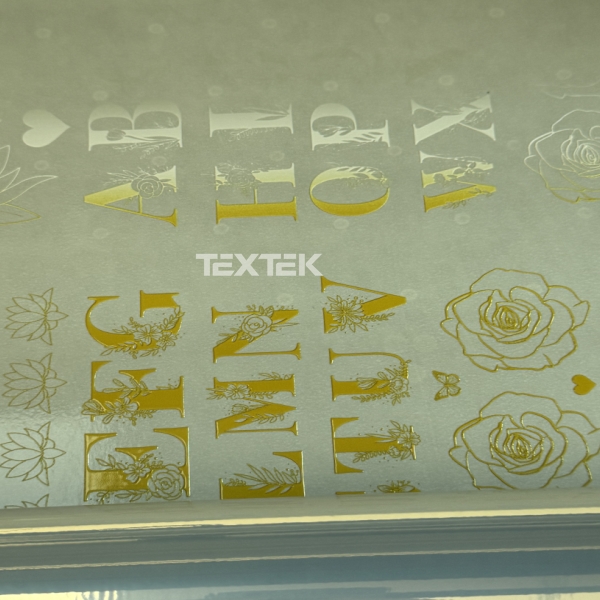

Bright color

High-definition colors and detailed dots

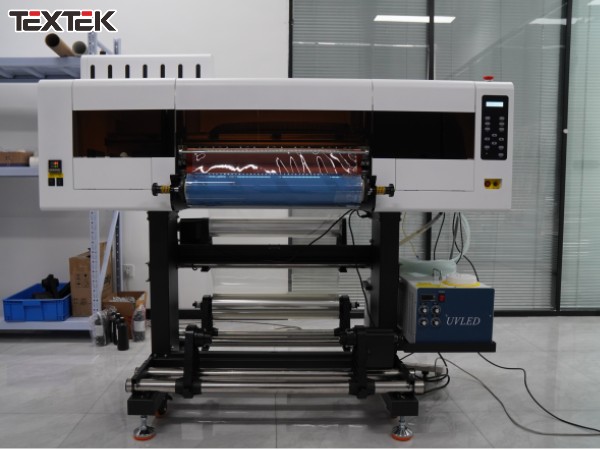

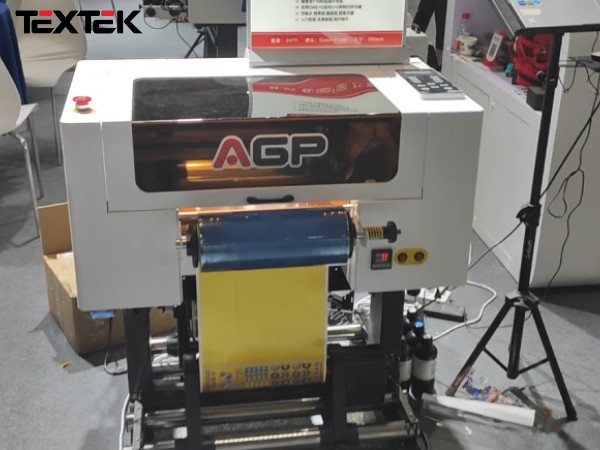

The UV DTF printer can realize one-piece printing without plate making. It can be printed and printed immediately, and it can be pasted and peeled off, which greatly saves all kinds of tedious operating steps and processes. Whether it is LOGO, trademark or pattern, it can be realized to meet various types of personalities. Meet customer needs for small batch customization.

UV DTF Printer has become an entrepreneurial artifact with small investment and quick return. Taking advantage of the trend, you can place an order for production if you have a machine. The manufacturer provides a wide range of consumables and application solutions, so even industry novices can quickly get started with the operation of the equipment.

It is foreseeable that crystal labels will be widely used. Whether in terms of performance or appearance, crystal labels have almost overwhelming advantages. Compared with ordinary self-adhesives, crystal labels have better weather resistance, are waterproof, sunproof, wear-resistant, high-temperature resistant, and have better adhesion. The ability to increase with time, one printing, short construction period, good effect, and high efficiency will be the reasons why crystal labels are widely used.

The difficulty of crystal marking is not the equipment, but the stable process plan. After the adhesion of a good crystal label film has passed the test, you still need drawing skills before printing. The properties of the ink and the temperature used for lamination also have a great relationship.

You also need to pay attention to the following three points:

1. The amount of white ink and varnish. The thickness of the white ink determines the three-dimensional effect of the pattern, and the thickness of the varnish determines the transfer effect of the crystal mark.

2. The choice of membrane paper. In fact, the equipment is not the difficulty in making crystal markers, the membrane paper is. The crystal label film is the key to determining whether the crystal label can be transferred completely and easily. High-quality film paper can firmly adhere to the pattern, but it is very easy to separate the two. Even millimeter-small characters can be easily transferred to the transfer paper.

3. The drawing plan. For small millimeter characters, small white ink, and small gluing area, the plan used for the varnish spot color channel is also very important at this time. The crystal marking paper has uneven layers. How to choose a high-quality and low-priced one? Crystal film paper with strong adhesion is the key to whether advertisers can print perfect patterns.

Personalized customization has become an expression of consumers’ lifestyles, and the market prospects are very promising. Catalyzed by the personalized customization market, crystal labels, a small and practical way of personalized expression, have been favored by a large number of consumers.

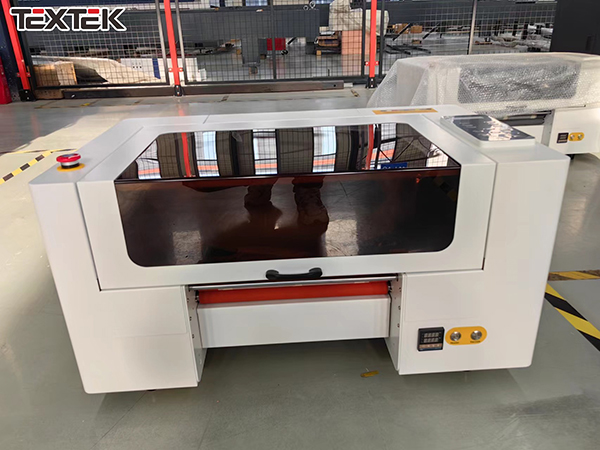

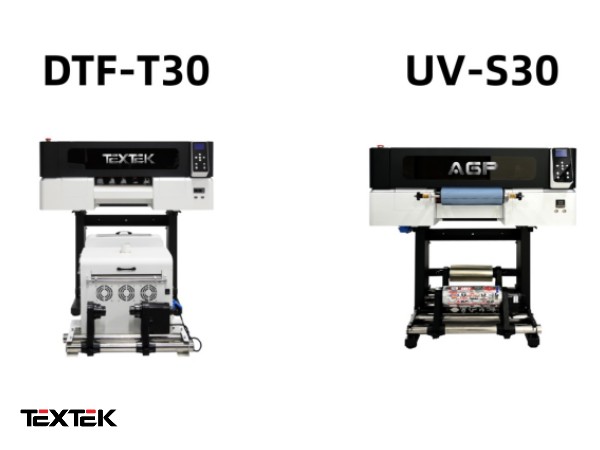

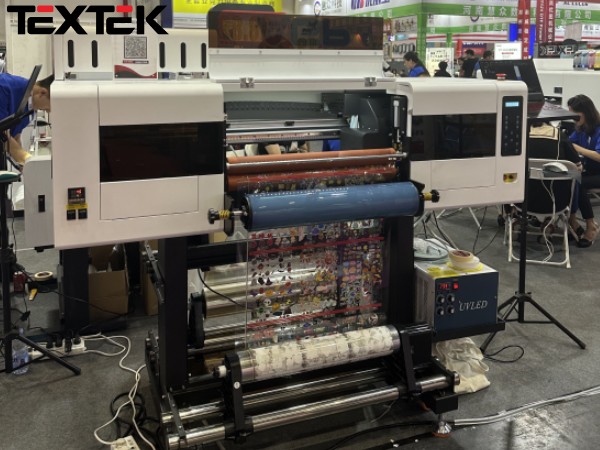

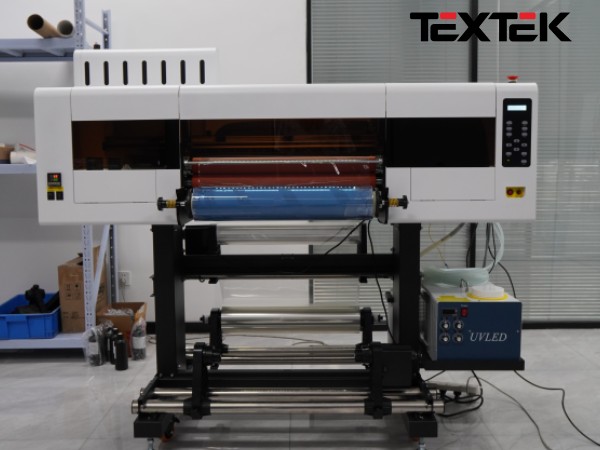

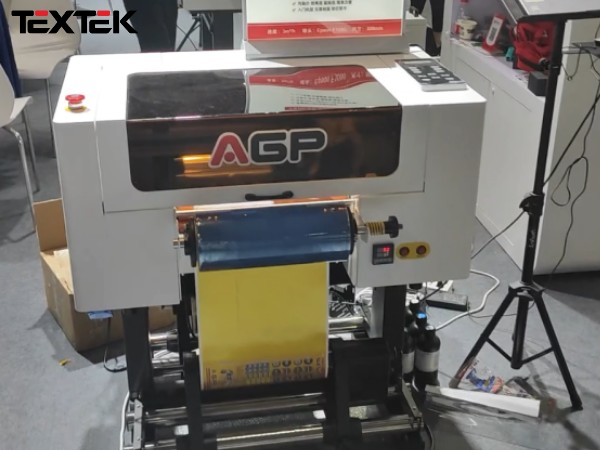

As more and more companies join the ranks of developing and producing crystal labels, it becomes even more important to choose a high-quality crystal label. After summarizing the existing printing processes on the market, TEXTEK summarized the advantages of each process, launched a more stable crystal mark printing solution, and launched the crystal mark printer UV-F30 UV-F604 (30cm 60cm optional). Materials used for the whole machine It is solid and uses high-quality spare parts. Important accessories such as nozzles use well-known brand Epson nozzles to ensure stable and smooth printing. In addition, using a more stable crystal mark printing solution and using high-quality consumables, the printed crystal mark has an accuracy of up to 2400 DPI, with bright patterns, rich colors, strong three-dimensional effect, high gloss, and is easy to pick up and separate during transfer without leaving any residue. Glue, the longer it dries, the stronger the adhesion, wear resistance, scratch resistance, water resistance and sun protection. The excellent equipment and process quality have been recognized by many new and old customers, who come to make drawings and place orders. The crystal labels are applied to a variety of products, becoming a perfect solution for small batch personalized customization. At present, TEXTEK UV DTF Printer batch processing and machine ordering orders are constantly coming in. One piece is being printed and orders are being received. Customers in need are welcome to contact us for details!

.jpg)