What’s the charm of Crystal sticker? How exactly is it different from traditional sticker?

1. The difference in process.

Step1

Design the printing film and printing version, prepare the main materials and auxiliary materials and mix the adhesive and printing ink beforehand.

Step2

Apply release silicone oil on the surface of high-density material.

Step3

Print the prepared adhesive

Step4

Printing of formulated protective primer

Step5

Printing the formulated ink of each color

Step6

Printing UV protective varnish, drying and curing by UV light.

Step7

Coat with high viscosity protective film, and finally cut the finished product.

In contrast, the process of crystal stickers is simpler and easier to use.

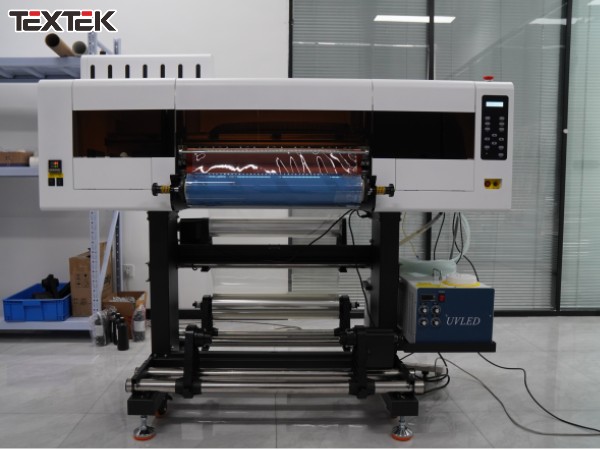

No need for plate making, no need for waste discharge, just confirm the pattern and start production. The UV DTF printer can be started with one button. There is no need for manual operation during the process, and an A3-sized sample can be printed after waiting for a few minutes. Moreover, the UV DTF printer is small in size and occupies a small area. This new machine just makes up for the market vacancy in the advertising industry for fast and convenient printing.

2. The difference in effect.

The traditional sticker process is limited by the process, the color is dull, not waterproof easy to lose color, does not support the printing of special complex styles.

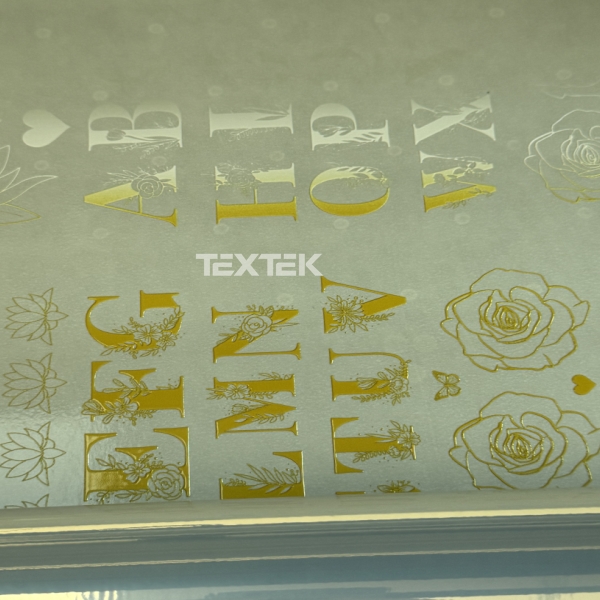

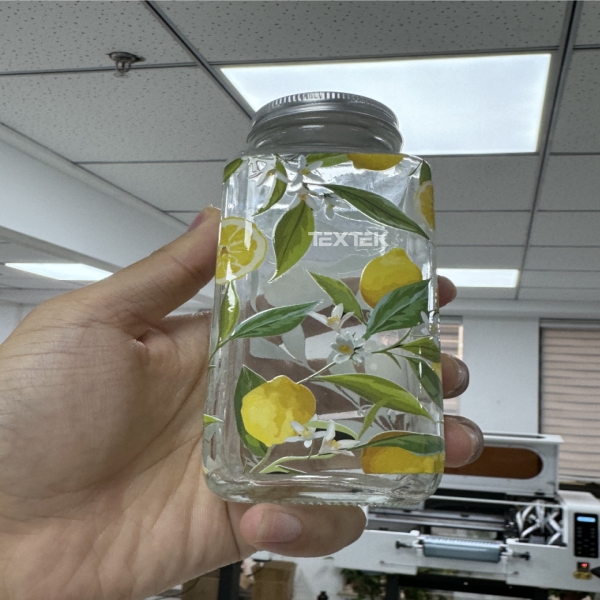

Crystal stickers support new technologies such as embossing, varnish, and complex pattern printing. They have a strong three-dimensional effect and are beautiful and atmospheric. Sticking to the surface of objects can increase the overall aesthetics. The finished product has a good release effect, is easy to re-post, does not fade, and is scratch-resistant and wear-resistant.

3.The difference in the number of MOQ.

Because traditional sticker requires plate making and mold opening, it generally has higher requirements for the number of MOQ printings, and is suitable for manufacturers with large-volume needs.

The crystal sticker has no MOQ limit, one sheet can be printed, and it can be printed as you want, which is more suitable for the public.

From the above three differences, it can be seen that the crystal sticker is an upgraded version of the traditional sticker process, which fills the previous market needs for the convenience, timeliness of manufacturing and good experience of the sticker market.

Crystal sticker technology has been widely used in real life, such as glass, ceramics, wood, acrylic board, PVC board, KT board, steel board, iron board, aluminum board, marble and other smooth and hard materials can be transferred.

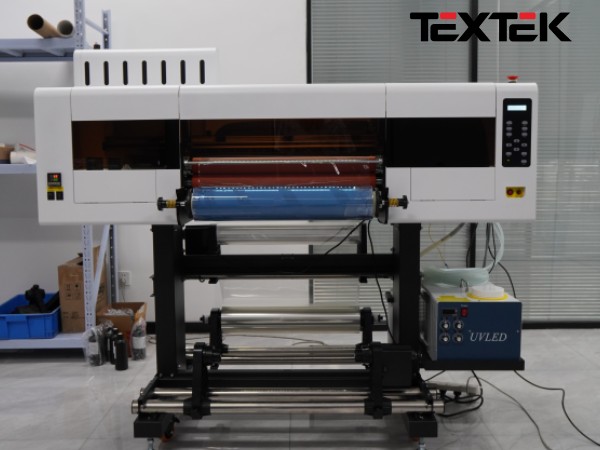

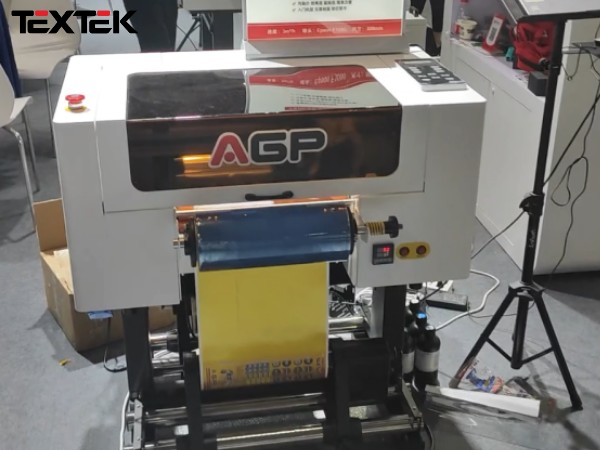

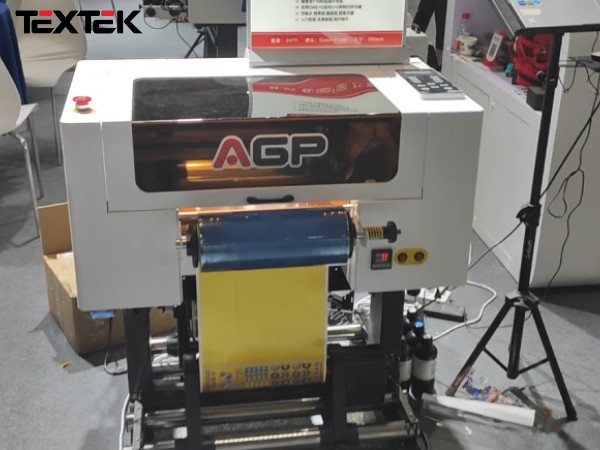

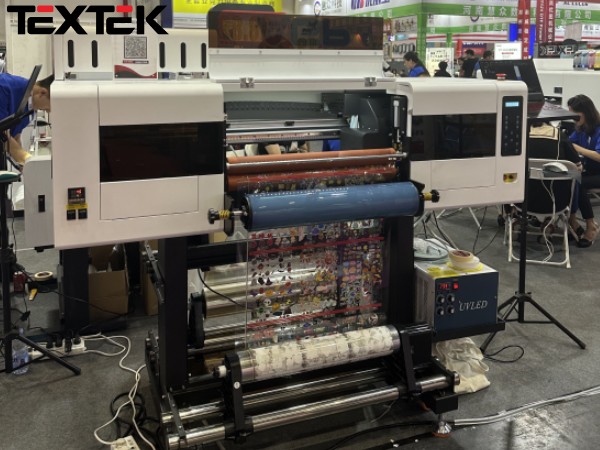

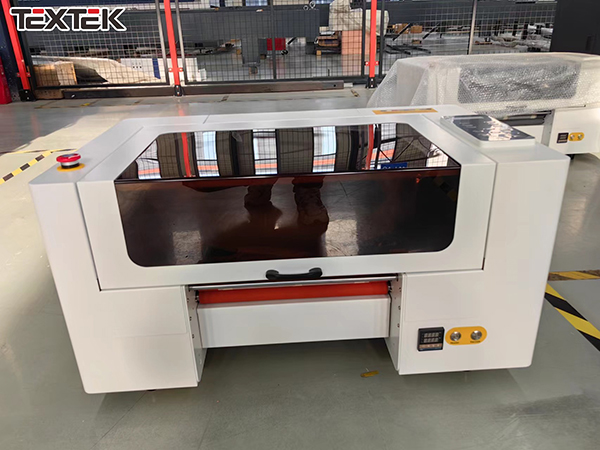

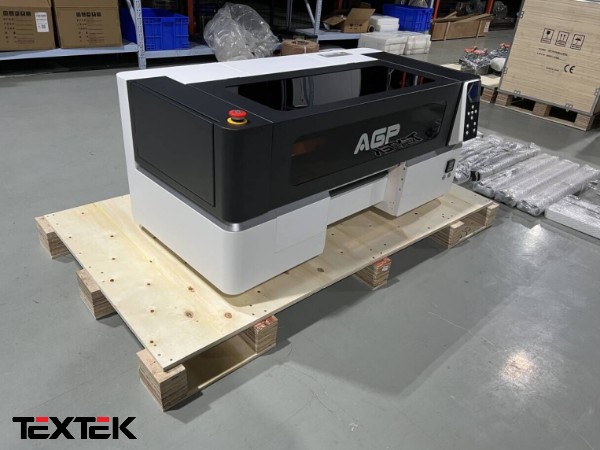

Following the market development trend, AGP launched the UV DTF printer: UV-F30 and UV-F60. 30cm/60cm two kinds of printing width are optional, the machine is equipped with Epson genuine print head, selects brand high-quality parts, configures a variety of humanized functions, supports two printing schemes: AB film and glue direct printing. The produced crystal stickers are bright in color, high in reduction, strong in adhesion, scratch-resistant and wear-resistant, have a strong three-dimensional surface, and leave no residual glue, and have been recognized by many new and old customers.

High-quality machines, customers in need are welcome to send inquiry!