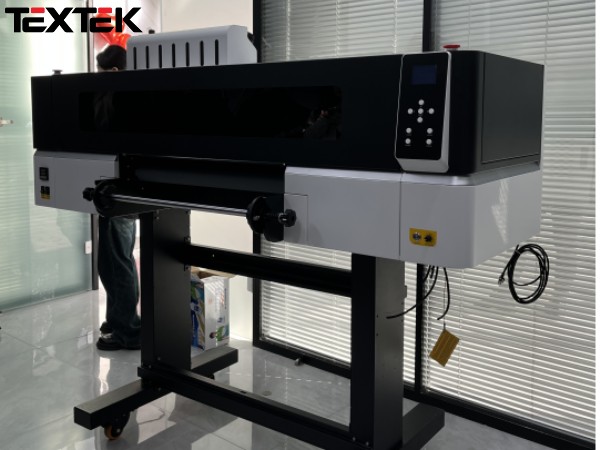

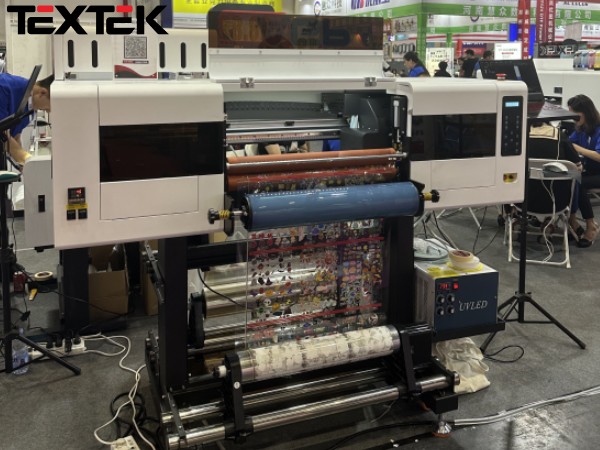

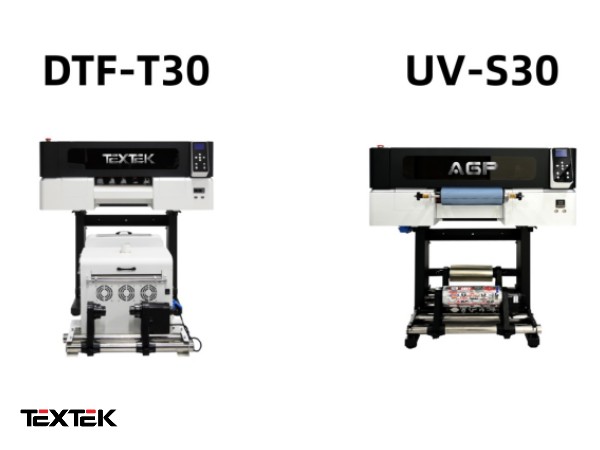

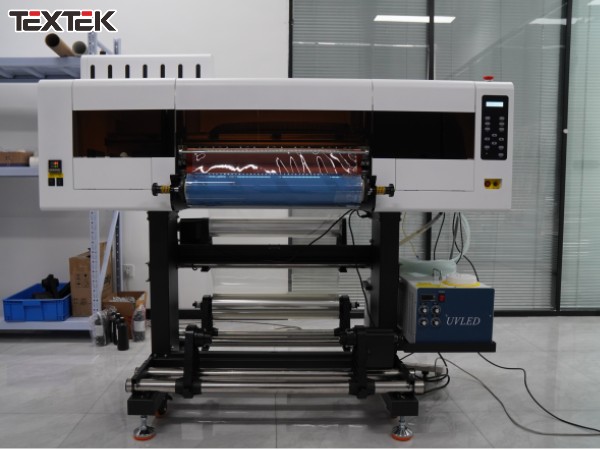

In addition to regular maintenance of the TEXTEK UV DTF Printer, daily maintenance of the TEXTEK UV DTF Printer is also essential. The printing condition of the machine directly affects the quality of the printed products. In addition, if the daily maintenance is done well, the service life of the machine will be extended and a lot of maintenance costs will be saved.

So how to maintain it correctly? Please check the following:

1. Daily nozzle maintenance

The nozzle is one of the most important parts of a UV DTF printer, so it needs to be treated with the most care. It is also the focus of daily maintenance.

1) After finishing work every day

① It is necessary to test the nozzle, leave the test ink strip after printing, and test again for comparison before working tomorrow.

② Return the nozzle to the top of the ink pad and allow the ink pad to continue to moisten the nozzle. Remember not to expose the nozzle to air, as UV DTF ink dries very quickly. When the machine is not operating, the nozzle must be placed above the ink pad. Otherwise, the ink will easily clog the nozzle as it dries. At the very least, the nozzle will need to be cleaned, and at the very worst, the nozzle may need to be scrapped.

2) Before work every day

① After turning on the machine, test the nozzle first. Compare it to the previous day’s test strip. If the ink is separated, clean the nozzle until the test strip is complete.

② After cleaning, test again until the ink strip is similar to the previous day.

To keep the nozzle in the best condition and to ensure that the nozzle is in good condition before printing, the nozzle must be tested before and after work. Otherwise, the quality of the printed products will be uneven, the entire product will be unusable, and a lot of consumables will be wasted.

2. Do a good job of avoiding light

Due to the nature of UV ink, it dries immediately when exposed to light, making light protection very important. Whether the machine is operating or idle, ink tanks, ink tubes, nozzles, etc. must be protected from light.

In addition, you should always check to see if the ink in the ink tank has dried up. If you find that the ink has dried up, replace the ink in time and stop using the original ink.

TEXTEK recommends that if your production requirements are not particularly high, you can choose a low-capacity ink. Once opened, the ink is exposed to light and must be used up in a short time. Small-capacity ink of 500ml and 100ml can meet the needs of many small manufacturers.

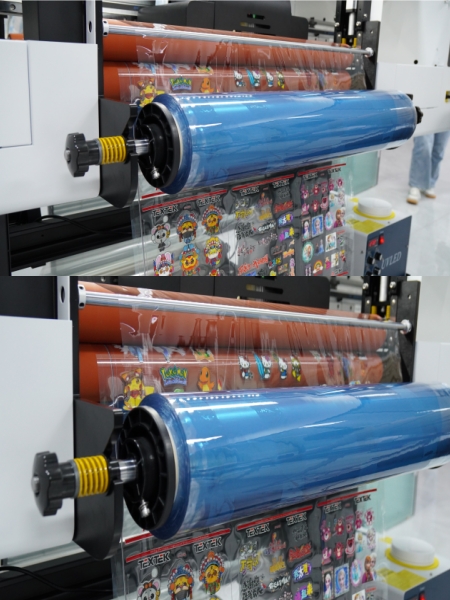

3. Keep the printing film dry and flat

4. Keep the machine clean and tidy

Before daily work, you must wipe off the dust and debris on the surface of the machine, as well as organize the environment around the machine to keep the working environment clean and tidy, and then turn on the machine. To prevent dust or other foreign matter from affecting the work of the machine, serious damage to the machine nozzle.

Routine maintenance of the TEXTEK UV DTF printer must become a daily habit to ensure that the machine operates optimally, reducing the occurrence of minor printer problems, but also greatly reducing the likelihood of major problems occurring. Assuming that problems are found, they should be dealt with in a timely manner.

.jpg)