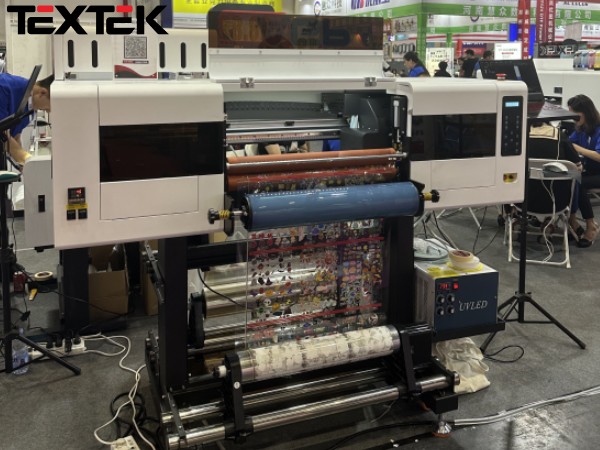

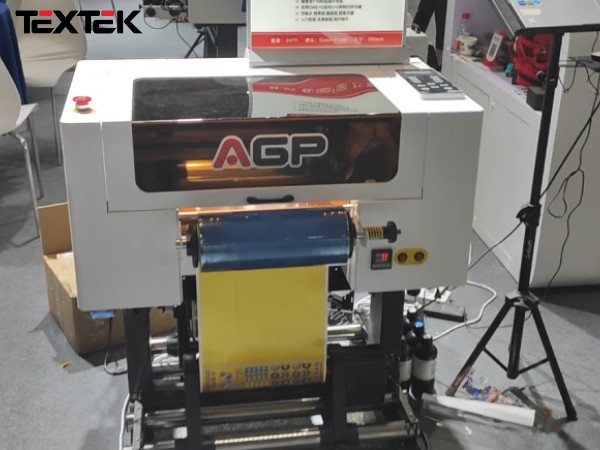

The traditional hot stamping process is generally: hot stamping preparation – plate installation, plate padding – hot stamping process parameter adjustment – hot stamping test – sample signing – formal hot stamping. The process is more complicated and cumbersome and requires a certain number of prints. Under the guidance of high-tech development, the crystal label process is also more convenient and intelligent.

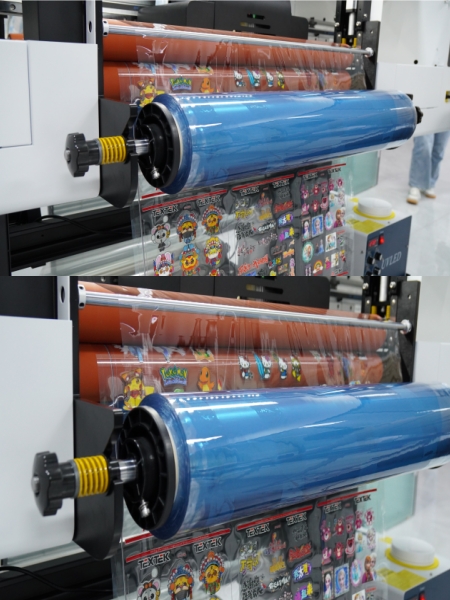

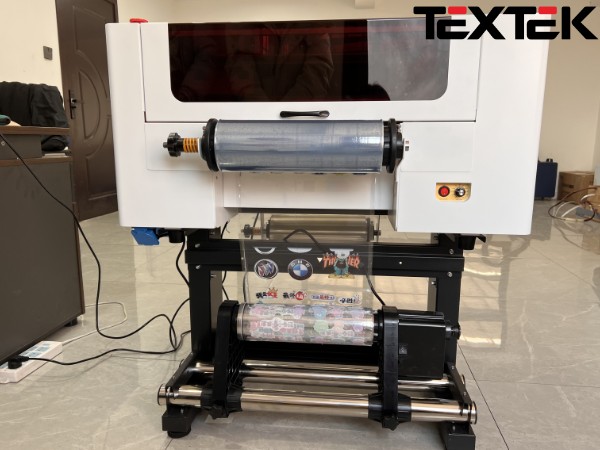

TEXTEK crystal label hot stamping process

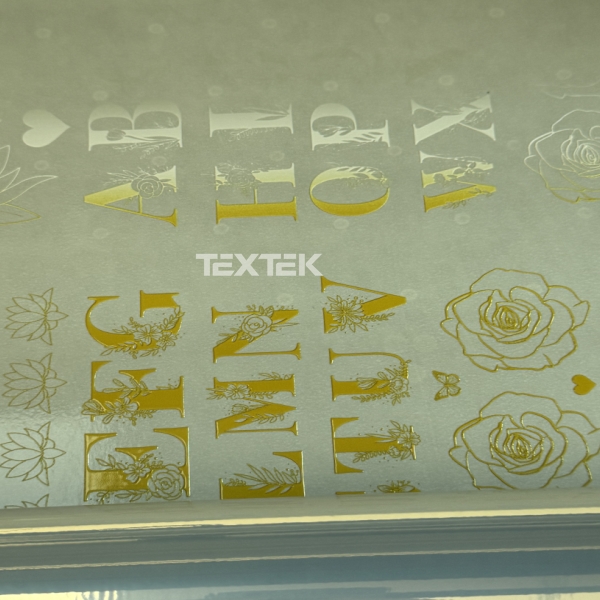

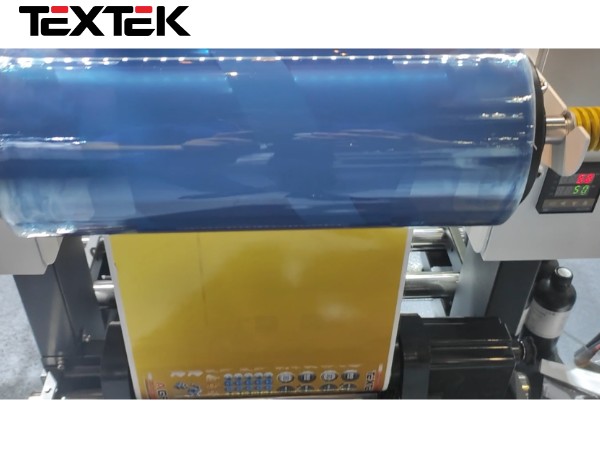

Our hot stamping process and varnish effect coexist, there is no limit to the number of prints, and the product has a wider range of applications. As long as it is a smooth and flat hard surface or curved surface, it can be transferred, with a strong sense of concave and convex, a more three-dimensional visual effect, and a more flexible way of use. One tear for a hundred uses, stick it on and use it. The printed product is not only clear and beautiful in pattern, but also resistant to daily scratches, in line with the trend of the times, but also line with the industrial concept of environmental protection, and is bound to become a popular trend.

Advantages of TEXTEK crystal label hot stamping

Eliminating the plate-making process, the hot stamping crystal label is naturally more cost-effective than the traditional hot stamping process, and the printing efficiency is high. Compared with the cumbersome hot stamping process of flatbed printers, the hot stamping crystal label can be done with one machine, which is more convenient for the public to use, easy to operate, simple and easy to use!

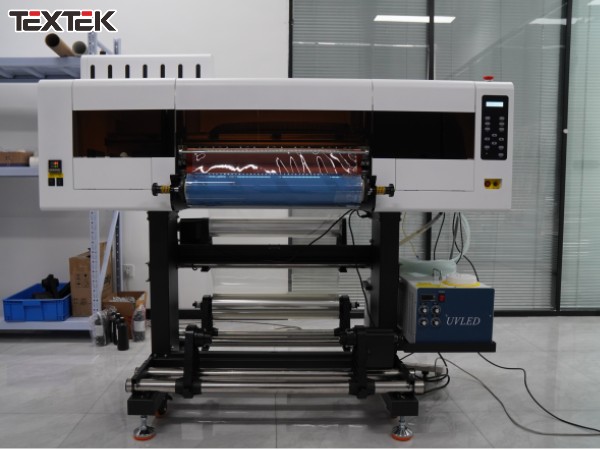

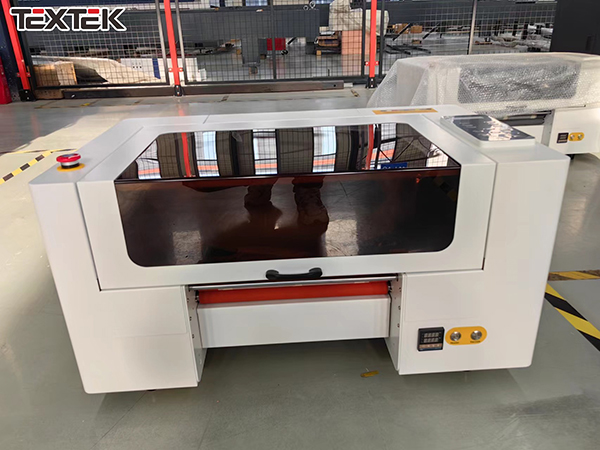

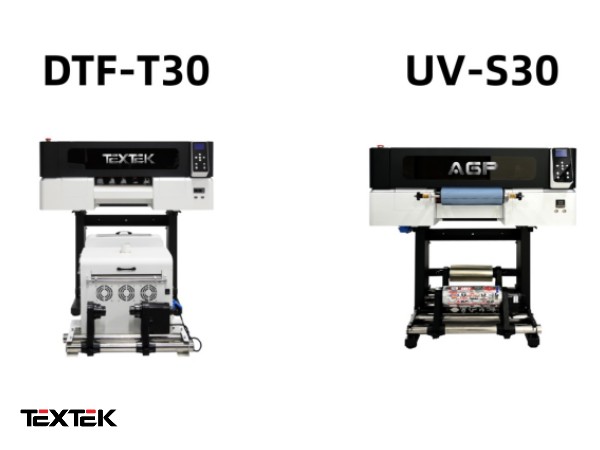

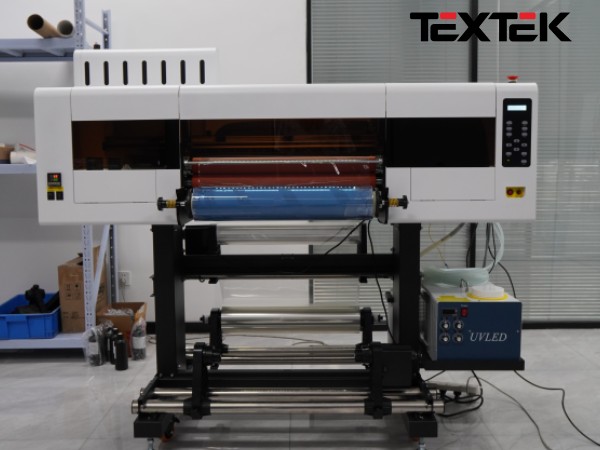

What is even more surprising is that such an improved process does not require any additional configuration. Both the UV-F604 and S604 models support the hot stamping solution for printing crystal labels. One press supports multiple printing solutions!

For example, the TEXTEK UV DTF Printer-F604, which supports two printing solutions, glue direct injection & UV AB film, is very cost effective and is equipped with original Epson I3200/I1600 nozzles, with a printing accuracy of up to 2160dpi and a printing speed of up to 10㎡/h. The machine is equipped with Hansen boards and has strong system stability. It only needs to be matched with the appropriate consumables. Whether it is a crystal label hot stamping solution or a self-adhesive hot stamping solution, it can be perfectly produced.

.jpg)