Troubleshooting Your UV DTF Printing Issues: Ensuring Optimal Adhesion

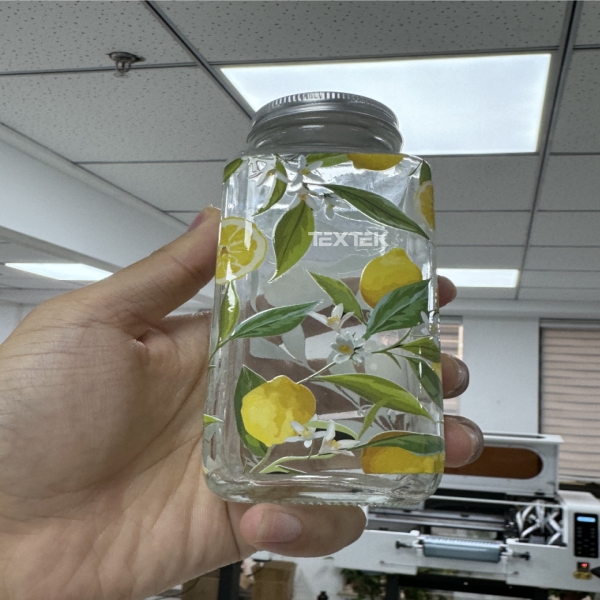

Why is my UV DTF not sticking?

1. Curing Parameters:

Incorrect curing temperature

Insufficient curing time

2. Application Pressure:

Inadequate pressure during the transfer process

3. Ink/Powder Quality:

Poor quality or incompatible ink or powder

4. Substrate Preparation:

Issues with the base material or substrate

Insufficient pre-treatment of the substrate

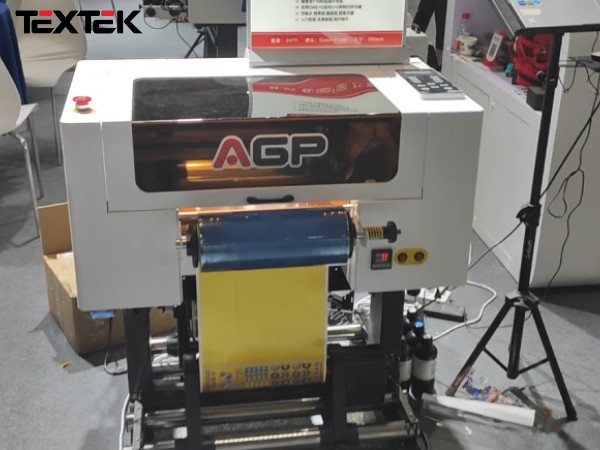

5. Printing Process:

Problems during the printing or transfer process

6. Environmental Factors:

Unfavorable environmental conditions, such as temperature and humidity

7. Ink/Powder Application:

Insufficient application of the ink or powder

Suggestions for Fixing UV DTF Transfers not sticking

- Curing Temperature and Time:

- Ensure the curing temperature and duration are optimized for proper bonding between the fabric and film.

- Try pressing at 320°F for 10-15 seconds, and consider doubling the press time by pressing again after the first session.

- Increase Pressure:

- Add more pressure to the press by placing a piece of cardboard under the press pad.

- Applying additional pressure can help improve the transfer adhesion.

- Multiple Press Passes:

- Try performing multiple press sessions to safely remove the transfer and ensure proper bonding.

- The additional press passes can help the transfer adhere more effectively.

- Adjust for Sensitive Fabrics:

- If the material heats up quickly, such as neoprene, reduce the temperature and time to prevent damage.

- Experiment with lower temperatures and shorter press durations for heat-sensitive fabrics.

- Maintain Cleanliness:

- Ensure the transfer containers and equipment are clean and free of any contaminants.

- Use the correct squeegee technique and apply the proper amount of pressure when applying the transfer.

- Check Material Compatibility:

- Verify that the DTF film and fabric you are using are compatible and recommended for your specific application.

- Incompatible materials can lead to adhesion issues.

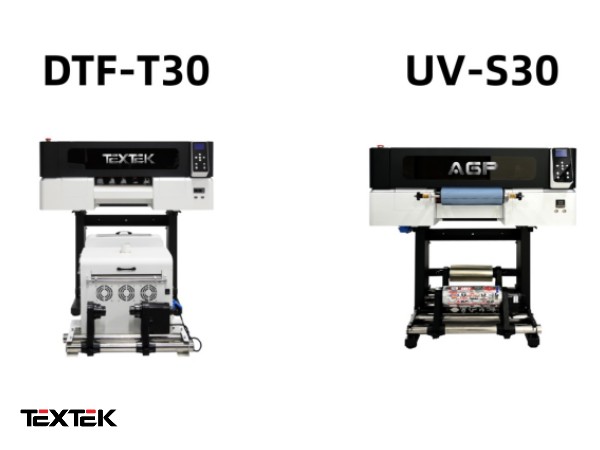

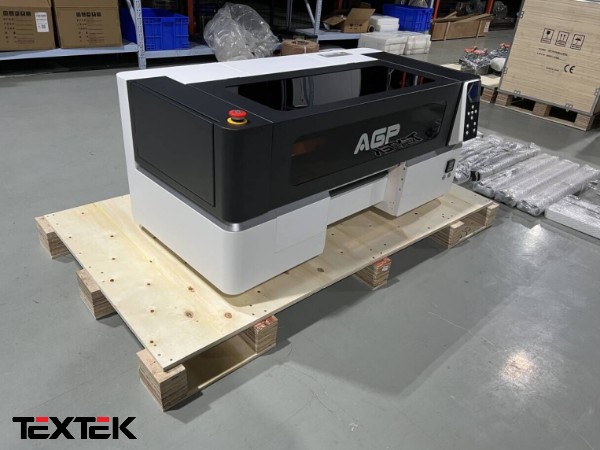

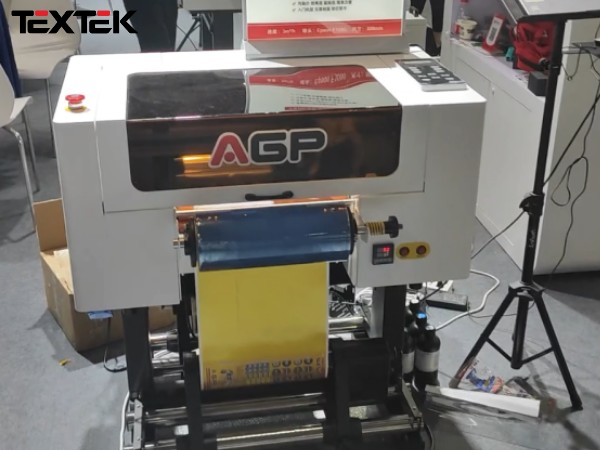

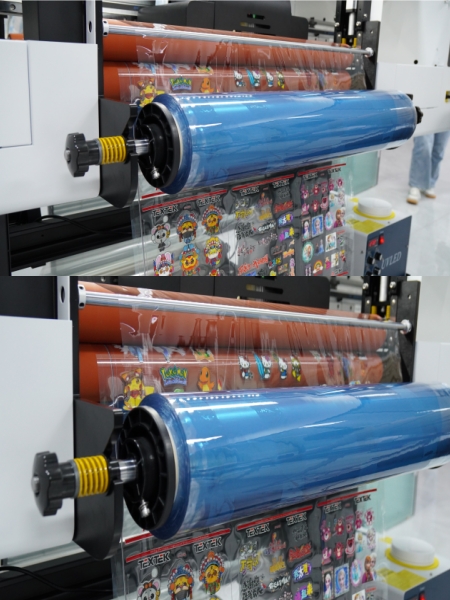

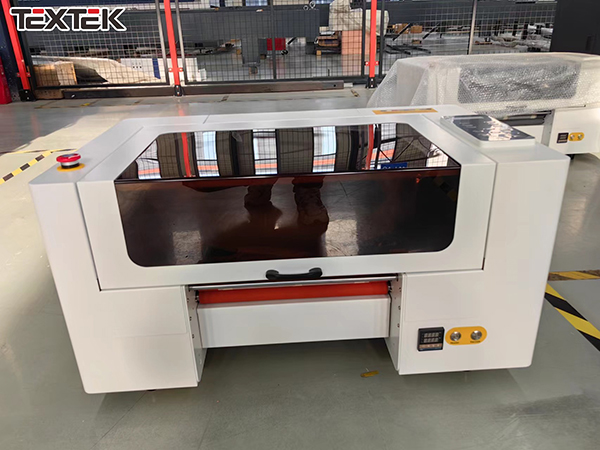

Welcome to TEXTEK! With nearly a decade in the printer industry, we specialize in R&D and manufacturing, offering exclusive DTF and UV DTF printer solutions. With a worldwide footprint, including partnerships with distributors in the USA, Canada, UK, Italy, and Spain, let’s unite to advance into the next stage of business expansion!

Drop us an email and let’s make great things happen: info@textek.cn

Contact us through WhatsApp and let’s talk furthermore: +8619137185989

.jpg)