Crystal labels have emerged as a popular choice for businesses looking to add a touch of elegance and sophistication to their products. These labels are made using advanced printing technology, which allows for high-resolution graphics and vibrant colors. In this article, we will explore the characteristics of crystal labels and how they can enhance the visual appeal of various products.

1.What is Crystal Label Technology?

Crystal label technology is an advanced labeling technique that utilizes specialized materials and printing processes to create labels with a distinctive appearance. These labels feature a crystalline or glass-like texture, adding a touch of elegance and sophistication to product packaging. Crystal labels are highly customizable, allowing for intricate designs, vibrant colors, and exceptional clarity.

2. Characteristics of Crystal Labels:

2.1. Visual Appeal:

Crystal labels are renowned for their exceptional visual appeal. The intricate details and vibrant colors achieved through this technology make products stand out on store shelves. The glass-like texture adds a premium look, enhancing the perceived value of the packaged items. Whether it’s cosmetics, beverages, or luxury goods, crystal labels elevate the overall aesthetic appeal of the product.

2.2. Durability:

Crystal labels are highly durable and resistant to various environmental factors such as moisture, heat, and UV radiation. The specialized materials used in their production ensure that the labels maintain their visual appeal and integrity even in challenging conditions. This durability makes crystal labels an excellent choice for products that require extended shelf life or may come into contact with liquids.

2.3. Flexibility and Versatility:

Crystal label technology offers remarkable flexibility and versatility in terms of design options. This technology allows for intricate patterns, gradients, and textures that were previously challenging to achieve with traditional labeling methods. Additionally, crystal labels can be applied to various packaging materials such as glass, plastic, and metal, making them suitable for a wide range of industries and product types.

2.4. Enhanced Branding Opportunities:

Crystal labels provide enhanced branding opportunities by enabling the incorporation of logos, slogans, and other brand elements with exceptional clarity and precision. The premium look and feel of crystal labels can help create a strong association between the product and the brand, leaving a lasting impression on consumers.

3. Crystal Label Production Process:

The production process of crystal labels involves several key steps:

Step 1: Design and Artwork Preparation: The label design is created using specialized software, considering factors such as product branding, packaging dimensions, and regulatory requirements.

Step 2: Material Selection: High-quality materials, such as specialized films or papers, are chosen to achieve the desired crystal-like effect.

Step 3: Printing: Advanced printing techniques, including UV printing or hot stamping, are employed to ensure vibrant colors, intricate details, and the desired texture.

Step 4: Coating and Finishing: A protective coating is applied to enhance durability and resistance against environmental factors. Additional finishing options, such as embossing or debossing, can be included for a more unique appearance.

4. Crystal Labels vs. Traditional Labels: A Comparative Analysis

To better understand the advantages of crystal labels, let’s compare them to traditional labeling methods:

| Characteristic | Crystal Labels | Traditional Labels |

|---|---|---|

| Visual Appeal | Glass-like texture, vibrant colors, intricate designs | Standard appearance, limited design options |

| Durability | Highly resistant to moisture, heat, and UV radiation | Susceptible to fading, peeling, and damage |

| Flexibility and Versatility | Allows for intricate patterns, gradients, and textures | Limited design capabilities |

| Branding Opportunities | Exceptional clarity and precision for logos and brand elements | Standard quality and limited branding options |

| Production Time | Efficient production process, shorter lead times | Longer production time due to multiple printing processes |

| Cost-effectiveness | Competitive pricing considering the aesthetic value | Cost varies based on design complexity and materials |

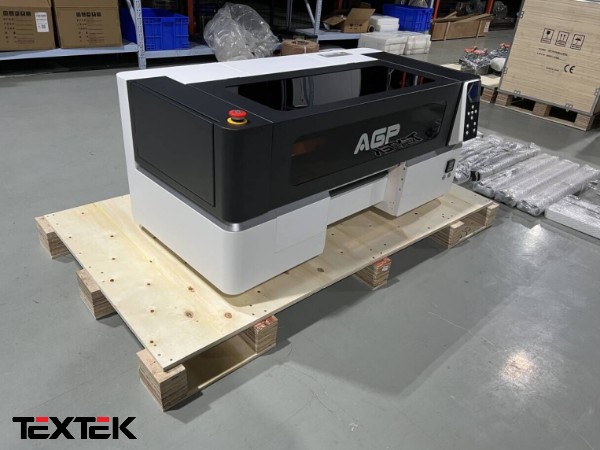

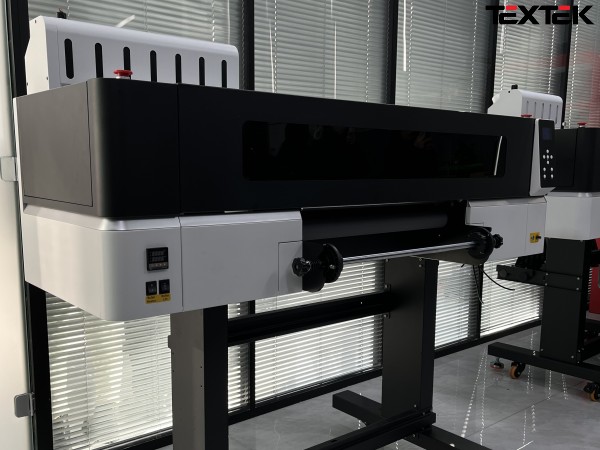

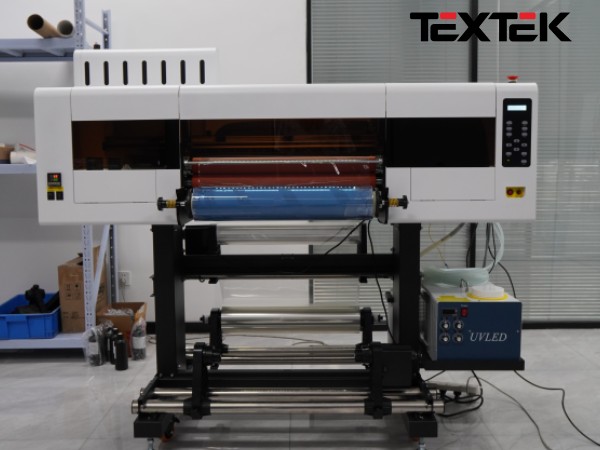

5.Printing Crystal Stickers with AGP&TEXTEK UV DTF Printer:

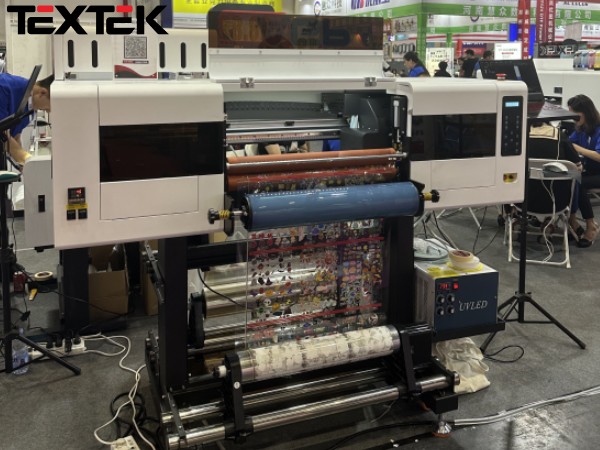

AGP&TEXTEK UV DTF printers have revolutionized the process of printing crystal stickers, offering exceptional print quality and precise reproduction of intricate designs. UV DTF (Direct to Film) printing technology combines the advantages of UV printing and DTF transfer methods, enabling the production of crystal stickers with stunning visuals and durability. Here’s an overview of the process:

Step 1: Design Preparation:

Using specialized design software compatible with AGP&TEXTEK UV DTF printers, designers create or import the artwork for the crystal stickers. This software provides tools to adjust colors, add effects, and optimize the design for printing.

Step 2: Preparing the AGP&TEXTEK UV DTF Printer:

The AGP&TEXTEK UV DTF printer is equipped with UV LED curing technology, allowing for instant ink drying and excellent color saturation. Before printing, the printer needs to be set up with the appropriate ink cartridges, and the printing bed must be prepared with a crystal sticker transfer film.

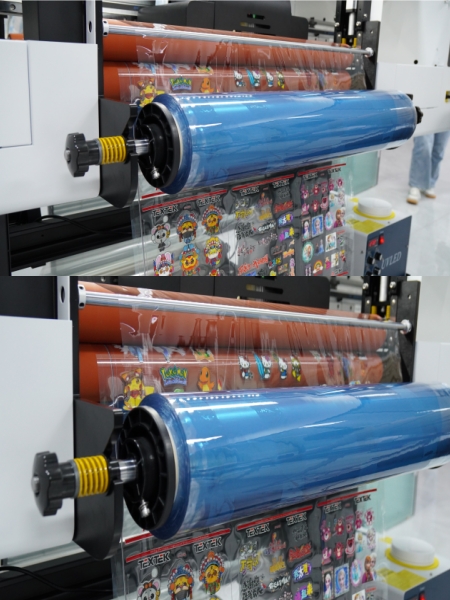

Step 3: Printing the Crystal Stickers:

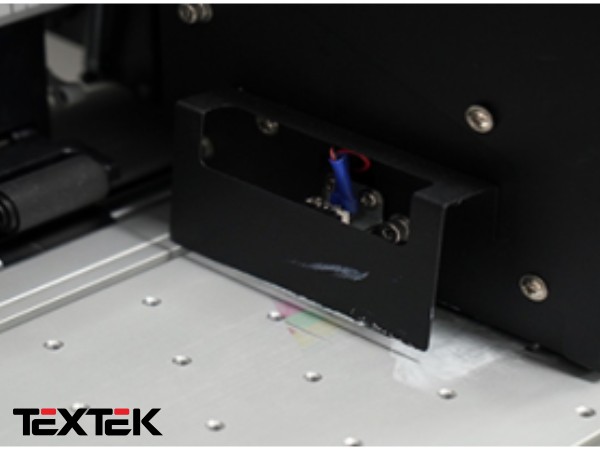

Once the printer is ready, the design file is sent to the AGP&TEXTEK UV DTF printer for printing. The printer applies UV-curable inks directly onto the crystal sticker transfer film using high-resolution printheads, ensuring accurate color reproduction and intricate details. The UV LED curing system instantly dries the ink, resulting in vibrant, smudge-resistant prints.

Step 4: Transferring the Crystal Stickers:

After printing, the crystal sticker transfer film is carefully removed from the printing bed. The printed crystal stickers remain on the film, ready for transfer. The stickers can be cut into individual pieces or left as a sheet, depending on the intended application.

Step 5: Application of Crystal Stickers:

To apply the crystal stickers, the backing film is peeled off, revealing the adhesive side. The stickers can be adhered to various surfaces, such as glass, plastic, or metal. The adhesive ensures a secure bond, allowing the stickers to withstand handling and environmental conditions.

6. The AGP&TEXTEK UV DTF printer offers several advantages for printing crystal stickers:

5.1. Superior Print Quality:

The high-resolution printheads and UV LED curing system of AGP&TEXTEK UV DTF printers ensure sharp details, vibrant colors, and excellent color saturation. This results in crystal stickers with exceptional visual appeal and clarity.

5.2. Durability and Resistance:

The UV-curable inks used in AGP&TEXTEK UV DTF printers provide excellent durability and resistance to moisture, heat, and UV radiation. Crystal stickers printed with this technology can maintain their visual integrity and withstand various environmental conditions.

5.3. Customization and Versatility:

AGP&TEXTEK UV DTF printers offer great flexibility in terms of design customization. The direct printing process allows for intricate patterns, gradients, and textures, enabling designers to create unique and eye-catching crystal stickers. Additionally, the printer’s compatibility with various crystal sticker transfer films provides versatility in terms of colors, finishes, and adhesive properties.

7.Applications of Crystal Labels

Crystal labels are used in a wide range of applications across different industries, including:

Product Branding: Crystal labels are commonly used to brand products such as electronics, appliances, cosmetics, and personal care items. The high-quality finish and customizable design options make crystal labels an effective tool for building brand recognition and loyalty.

Promotional Products: Crystal labels are often used on promotional items such as keychains, magnets, and badges. The eye-catching appearance of crystal labels can help increase brand visibility and leave a lasting impression on recipients.

Industrial Labels: Crystal labels are also used in industrial applications for product identification, equipment labeling, and asset tracking. The durable construction and weather-resistant properties of crystal labels make them ideal for use in challenging environments.

In conclusion, AGP&TEXTEK UV DTF printers have significantly advanced the printing process of crystal stickers. Their precise printing capabilities, exceptional print quality, and durability make them a preferred choice for producing crystal stickers with stunning visuals and high resistance to environmental factors. With the ever-evolving capabilities of AGP&TEXTEK UV DTF printers, the future of crystal sticker printing holds even more exciting possibilities for the packaging and labeling industry.

.jpg)