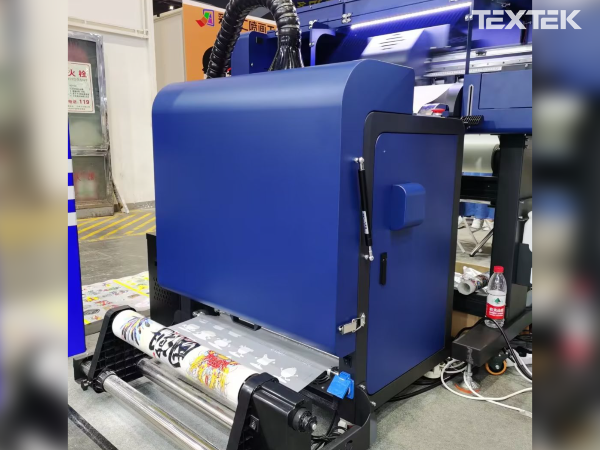

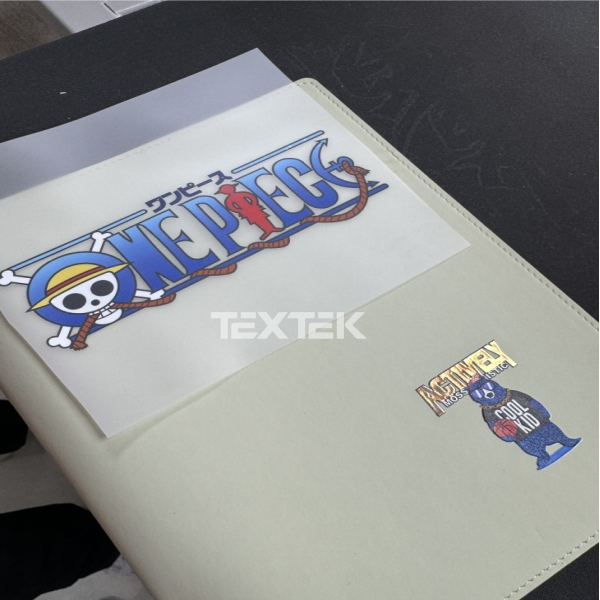

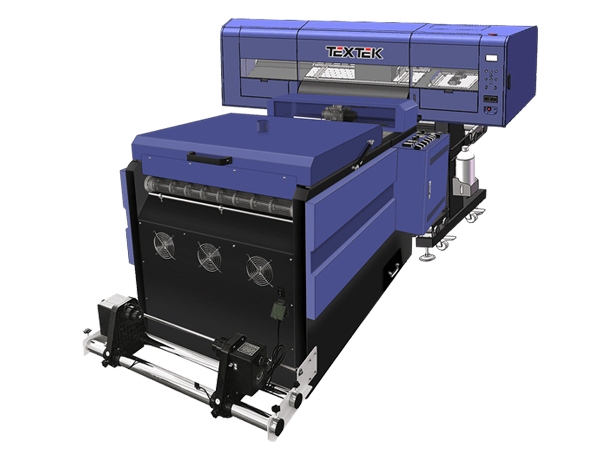

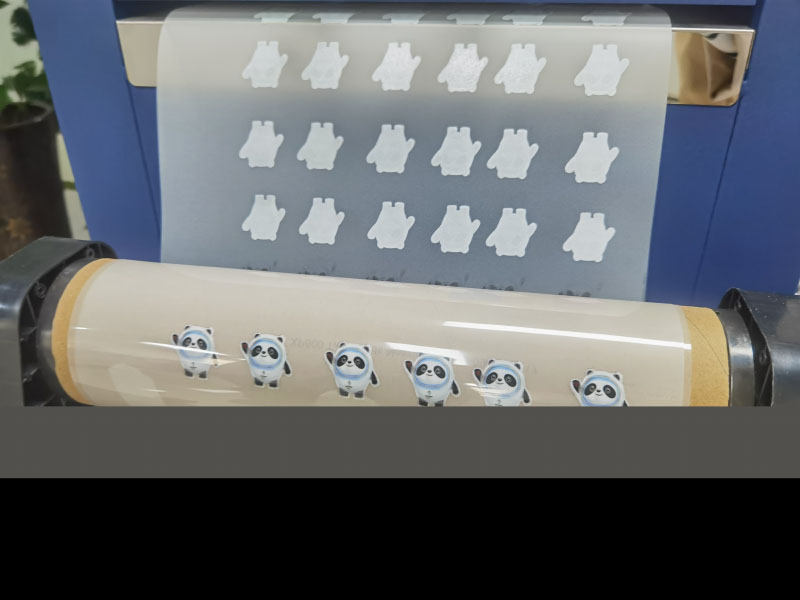

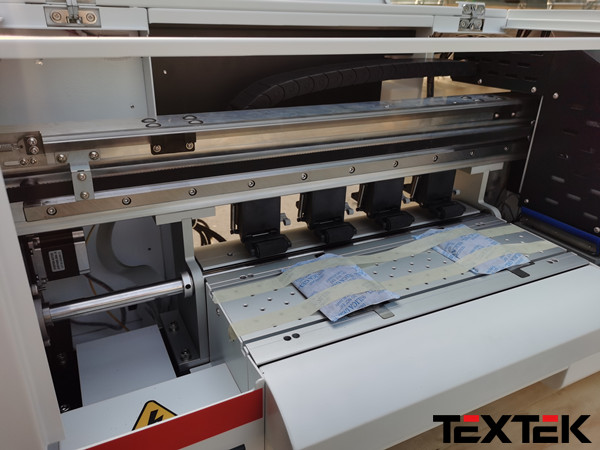

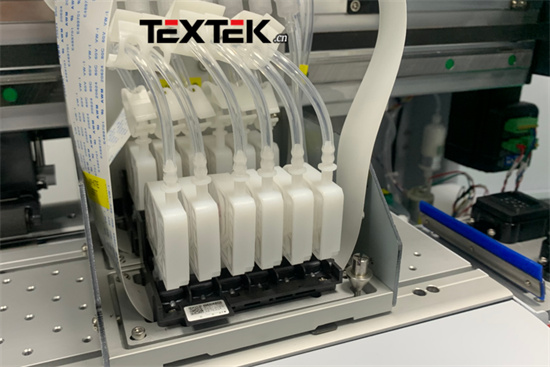

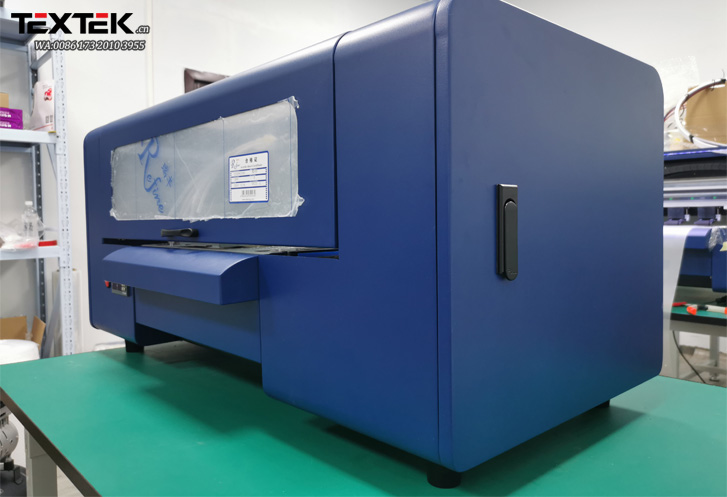

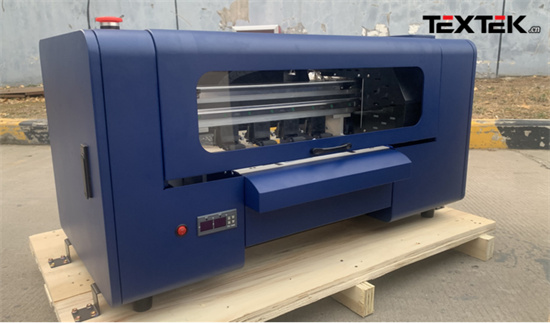

There are many kinds of garment printing processes, and the most widely used is the DTF process. White ink heat transfer printing process products have become a beautiful landscape in our lives. Clothing, home textiles, home life, etc. are inseparable from the white ink heat transfer printing process. The main reason why the white ink heat transfer process can quickly become popular is mainly the customization of personalized products. At present, many young people are walking on the forefront of the trend, and their demand for customized products is also increasing, which directly leads to an increase in the demand for white ink heat transfer printing printers.

The white ink heat transfer printing process does not require plate making, and a single piece can be produced. High environmental protection, white ink heat transfer printing process is a green and environmentally friendly production method, no waste, waste water discharge, and less pollution. The white ink heat transfer printing process has high precision and good printing effect. Printing high-precision patterns such as color gradients and moiré patterns expands the design space of textile patterns.

The white ink heat transfer printing process has low printing cost and high efficiency, and the cost of small batch printing is lower than that of traditional printing. The white ink heat transfer process has laid a foundation for adapting to the multi-variety and small-batch market. The heat transfer process is different from other printing processes. Other processes always have some limitations. For example, the main limitation of the direct injection process is on the fabric, while the screen-printing process is only suitable for large batches. The price of small batch production is very good. of. The white ink heat transfer does not need to pick the fabric or the pattern, and the finished product is printed immediately, without waiting, and there is no inventory risk. It is a new printing process that truly caters to the 22nd century.