It’s cold, the machine should also pay attention to keep warm.

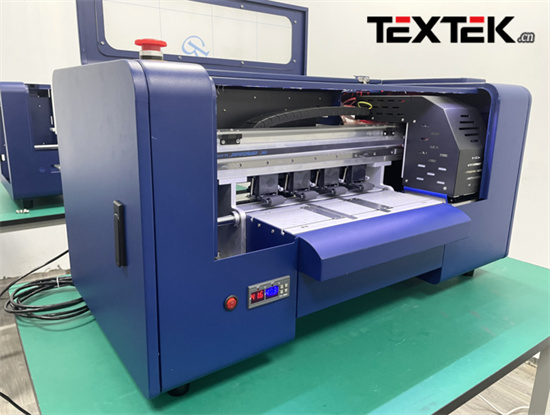

As the weather gets colder, climate temperature changes lead to significant temperature differences between regions. The working environment and the temperature of the environment are very important to the dtf printer. If the temperature is too low, the dtf printer will have phenomena such as oblique spraying, flying ink, and false images. Due to the cold and dry climate in some areas, there are some problems with dtf printers. We give the following five related protective measures for common problems.

1. When the user finds that the image of the test strip is blurred, he can use an electric heating fan or a hair dryer to heat up the nozzle to avoid such problems when the dtf printer is working.

2. Before using the dtf printer, the user should turn on the air conditioner or electric heating fan in advance to preheat the working environment of the dtf printer. The temperature can be maintained at 15℃-30℃, so that the dtf printer is in a better working state, which not only improves the work efficiency, And the printing effect is also excellent.

3. It is easy to generate static electricity in winter. Excessive static electricity will increase the work loss of the dtf printer and affect the life of the print head. You can reduce static electricity according to the following three tips:

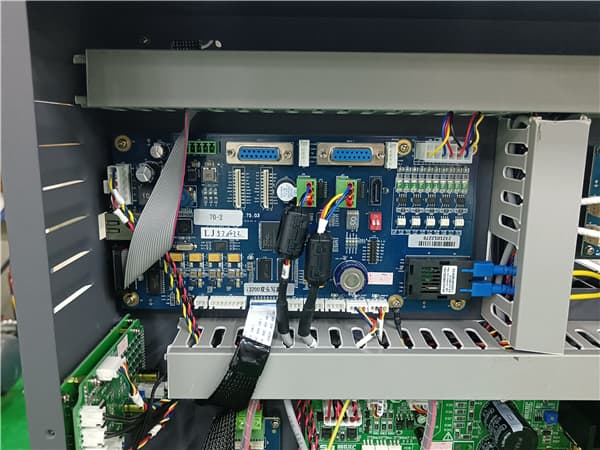

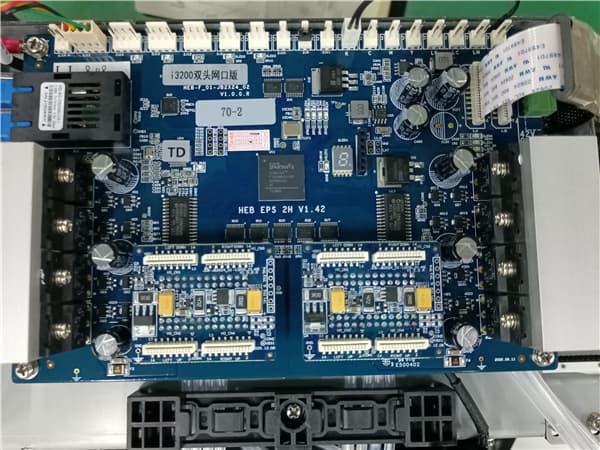

(1) The user can use a humidifier to increase the air humidity, and the humidity should be kept at 35%-65%. The humidifier should keep a distance from the dtf printer board to avoid condensation of water droplets and cause a short circuit of the board.

(2) An external ground wire is connected to the dtf printer, which is buried underground with a depth of not less than 2 meters. Salt water can also be poured in the burial to enhance conductivity.

(3) Pay attention to control the printing speed to prevent excessive static electricity.

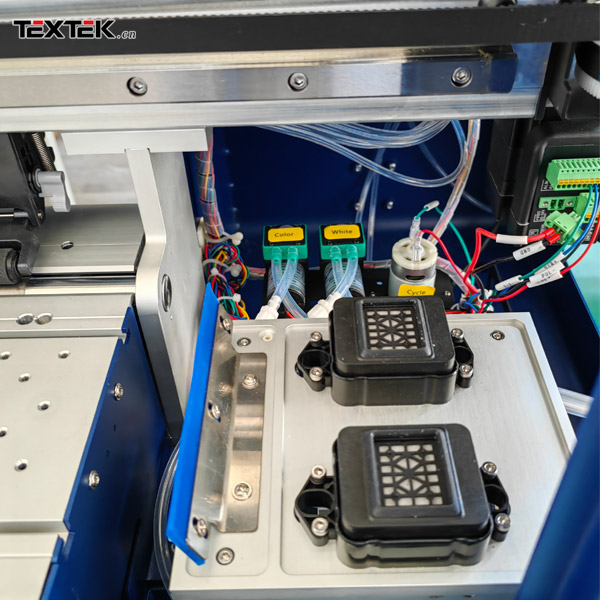

Fourth, dust is easy to block the nozzle, causing the printed image to be disconnected, so pay attention to cleaning the nozzle regularly to prevent dust from blocking the nozzle.

5. Too low temperature will also change the viscosity of T-shirt printer ink, especially low-quality ink. In winter, the viscosity of ink will increase, which will block the nozzle and cause oblique jetting and ink breakage, which will affect the life of the nozzle.

.jpg)