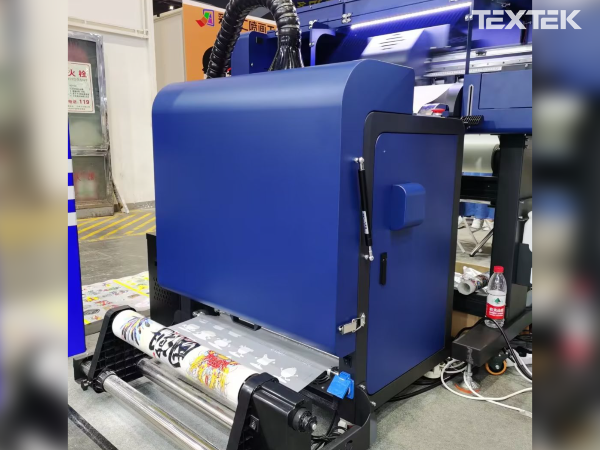

Recently, many printing companies have introduced digital heat transfer printing equipment, but because they have no experience in digital heat transfer printing production, many customers and friends will have some problems in use. Digital heat transfer printing machines are used as customized printing products The most important equipment must be maintained every time it is used for a period of time, otherwise it will affect the precision accessories, thereby affecting the printing effect of the digital heat transfer printing machine.

1. Whether the waste ink tank is full, the digital printing machine needs to use ink for printing, and there will be waste ink during the printing process. At this time, the waste ink tank must be cleaned in time.

2. Whether there is air in the ink tube of the ink cartridge, this must be paid attention to. If there is air entering, the ink will agglomerate, which will cause the ink not to flow smoothly. Please clean the ink tube of the ink cartridge at this time.

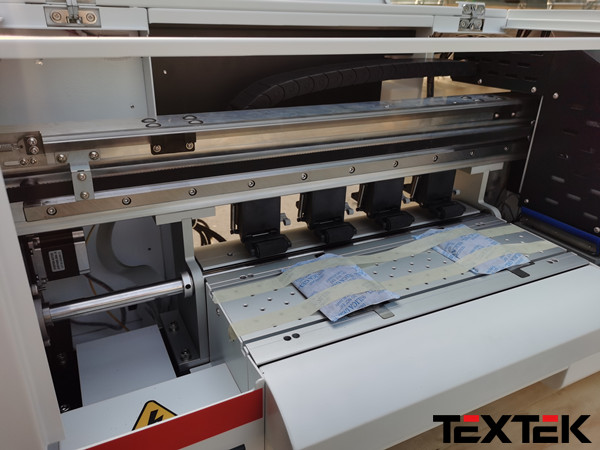

3. For the ink inlet pipe, you must check whether the print head is in good condition before production. If there are sporadic disconnections in the print head, please clean it, otherwise the printed products will be almost all waste products.

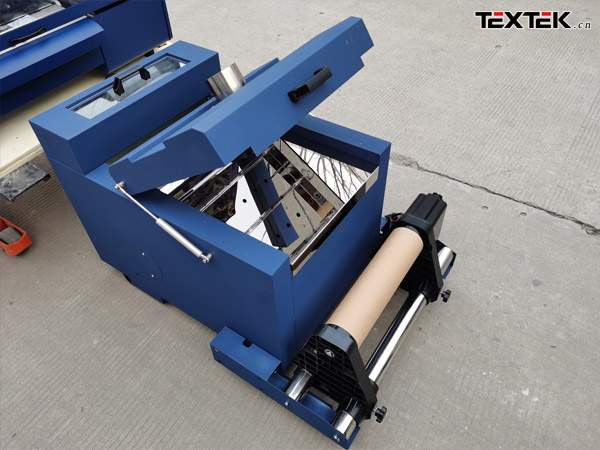

4. Oil the belt. It is recommended to apply some grease on the belt. At the belt position at both ends of the printer, the grease can pass through the belt, thereby transferring it to the grinding-in position of the gear and the belt.

5. To clean the ink stack, first move the cart out of the position of the ink stack, and then turn on the test function of the ink pump. At this time, slowly pour the prepared water into the ink stack for cleaning. If there is a relatively dirty ink stack, you can use a scraper to clean it, or you can use a wet wipe or white cloth dipped in water and wipe it clean.

Under normal circumstances, the grating should be checked and cleaned every three months. When cleaning, you can use a white cloth dipped in alcohol and wipe it before cleaning. And if the environment is poor, it is recommended to clean it once a month or even less.