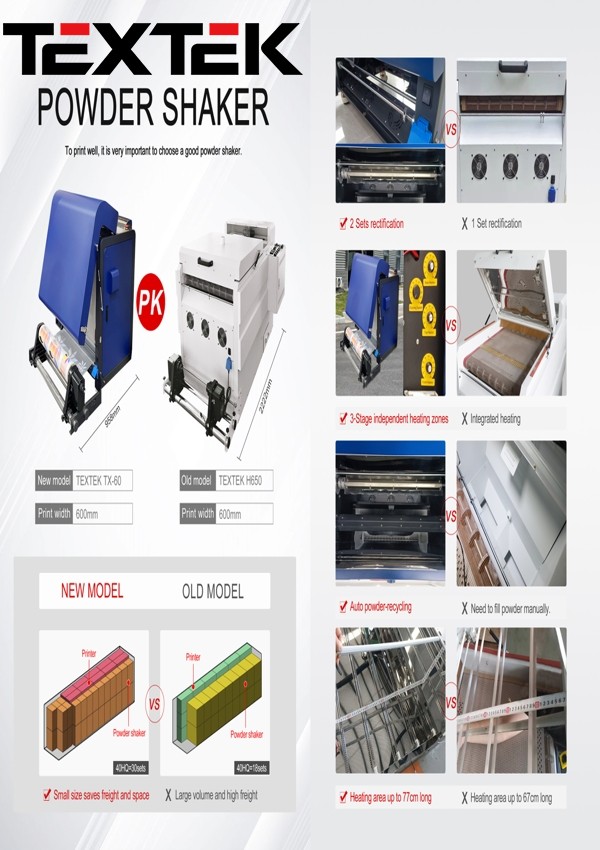

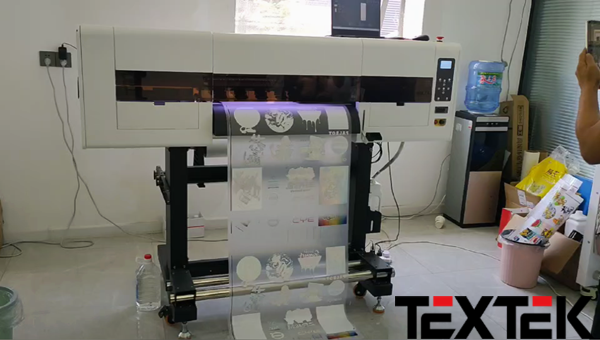

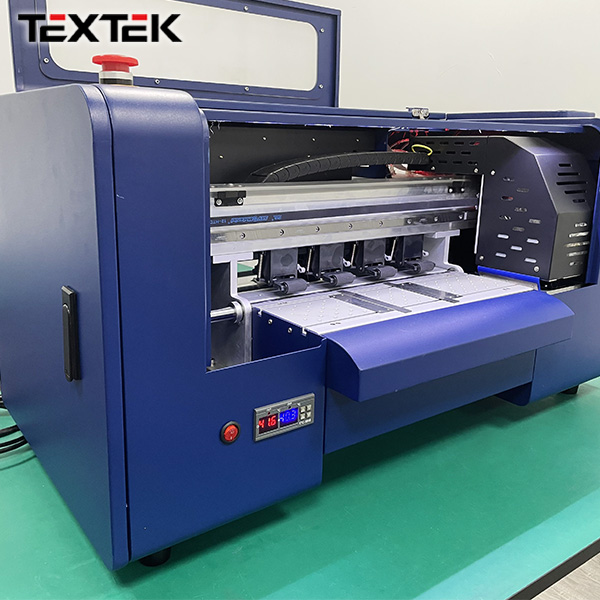

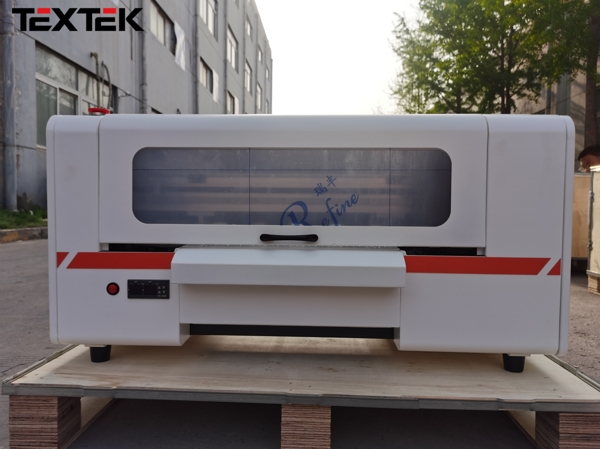

Textek Factory Directly Supply A3 30cm Dtf Printer for DTY Garment Shop

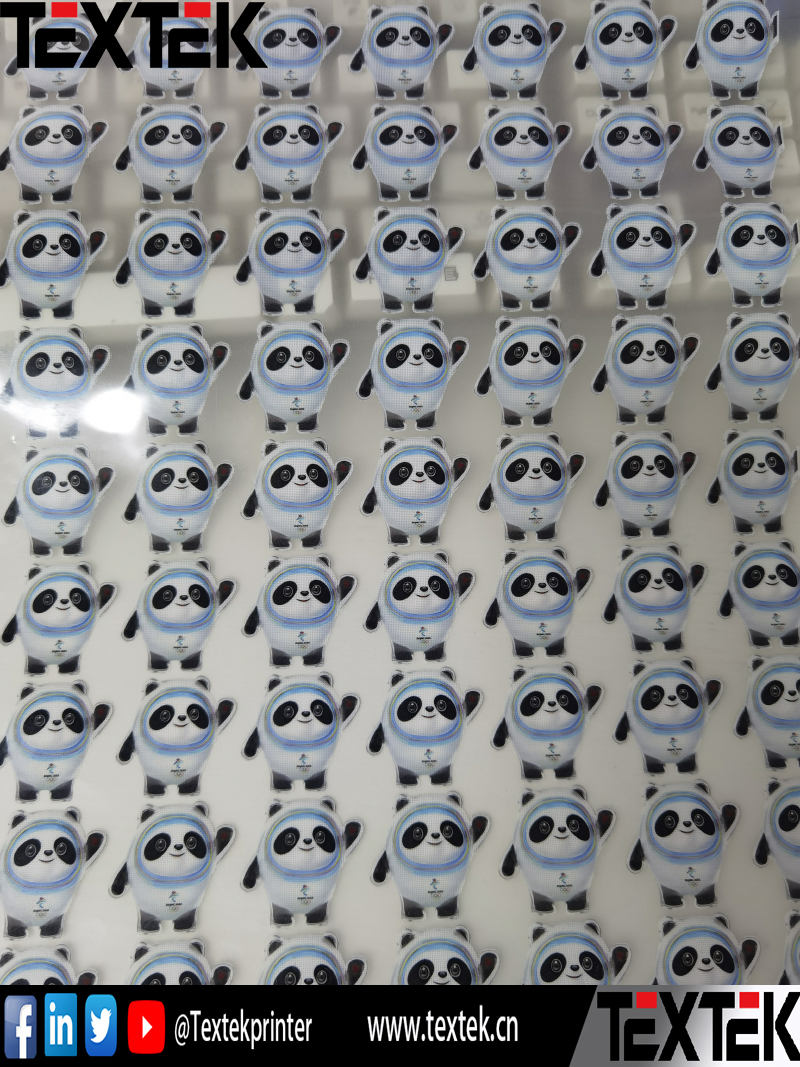

Textek DTF printerwill work on almost any fabric and has a much lower application heat – so no heat marks on sensitive fabrics. Sharper and more Vibrant prints compared to DTG. Finished product cost is 75% cheaper than DTG.

Printhead: 2*EPSON XP600

Printing Speed: 3.5-4.5sqm/h

Print Width: 30cm(12 inch)

Ink: CMYK+W Pigment Ink

Ink Color: 6 Color Printing

RIP Software: Maintop, Photoprint

Textek Factory Directly Supply A3 30cm Dtf Printer for DTY Garment Shop

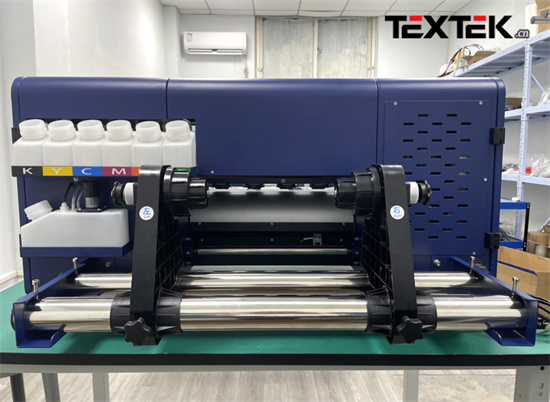

| Printer Head | XP600 2PCS |

| Production Speed and accuracy | 6 pass:4.5sqm/h 8 pass:3.5sqm/h |

| Main Board | Honson |

| Ink | water-based DTF ink; CMYK+WHITE(2 fluo colors are optional) |

| Color Manage | ICC or density curve |

| Print Media | PET Film |

| Print Width | 300mm |

| RIP Soft | Main Top |

| Operate system | Windows xp win7 or above |

| Power | 50HZ/60HZ,220V/110V 10A |

| Document Format | BMP/TIF/JPG/EPS/PDF |

Here are some of the challenges DTG faces:

• The print speed is slow, about 20 full-width front pages per hour.

• Steep learning curve and expensive equipment costs.

• DTGs are mostly limited to 100% cotton and print inconsistent results on different fabrics and colors.

• Dark garments need to be pre-treated and ironed before printing, which is time-consuming and labor-intensive.

• Ink and pretreatment are expensive. DTF can save you up to 75%!

• Only print on a flat surface suitable for the machine.

• Colors are inconsistent and inaccurate when printing on white or color.

Here are some of the challenges of screen printing:

• Extensive learning curve, requiring a lot of expensive equipment.

• Complex processes ranging from art setup, film printing, screen burning, color registration, messy inks and complex curing. More processes, more questions!

• Requires significant space and labor costs to print efficiently.

• Setup for complex jobs takes hours and requires manual mixing of custom colors.

• Difficulty finding a qualified and reliable workforce for growth.

• Not cost effective for low volume production with multiple colors.

• The fabric needs to be in a single layer and fastened to the pallet. Can’t print on double fabric or pockets!

DTF Printer Features:

- Free edition, fast printing speed, low cost, instant, low power consumption, breaking the

limitations of traditional color printing production, can print any type.

- The integrated design of printing white + color composite process reduces the printing cost of the darkest fabric and increases the production capacity.

- The machine has the function of skipping white, which can save more time for users.

- The built-in software can be used for printing emergency, and the pause function can wait for the problem to be solved before printing, which avoids the user’s property loss.