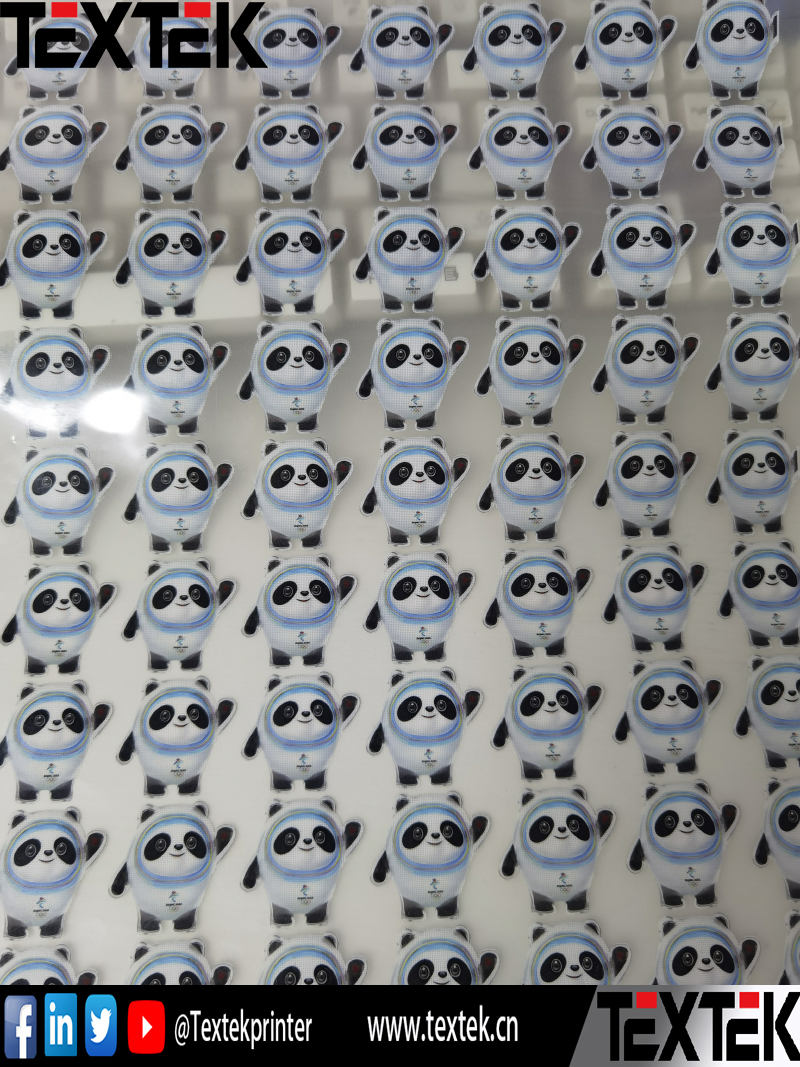

Textek Digital T Shirt Textile Printing Machine,Bing Dwen Dwen Senior DTF Printing,PET Film Transfer

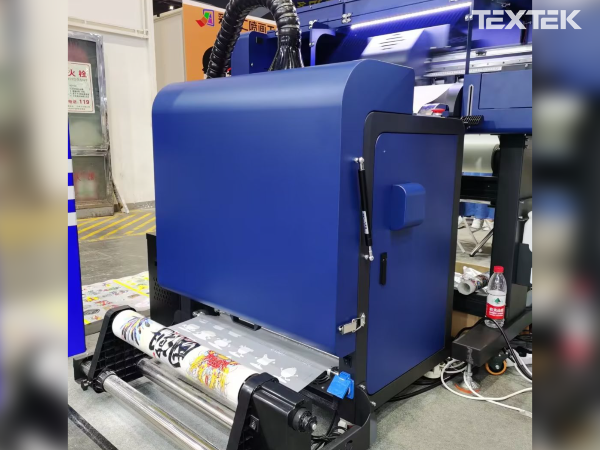

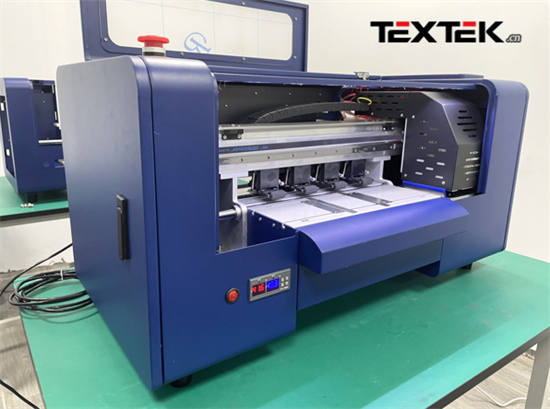

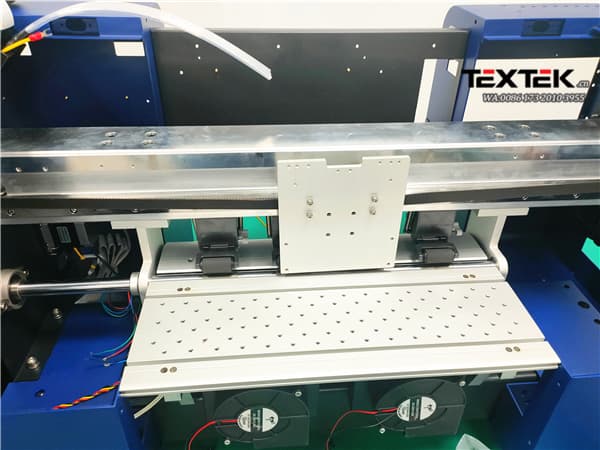

Model: Tk-A3 Pro (A3 DTF Printer)

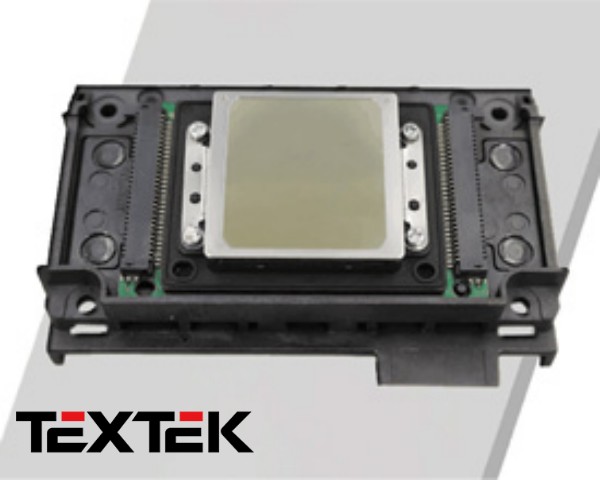

Nozzle Model: 2*Epson XP600

Printing speed: high speed mode 4.5©O/h

HD mode 3.5©O/h

Color: 4C+W or 6C+W (Lc Lm or fluorescent light optional)

Print Format: 300 mm (12 inches)

Media Transport: Paper Tension

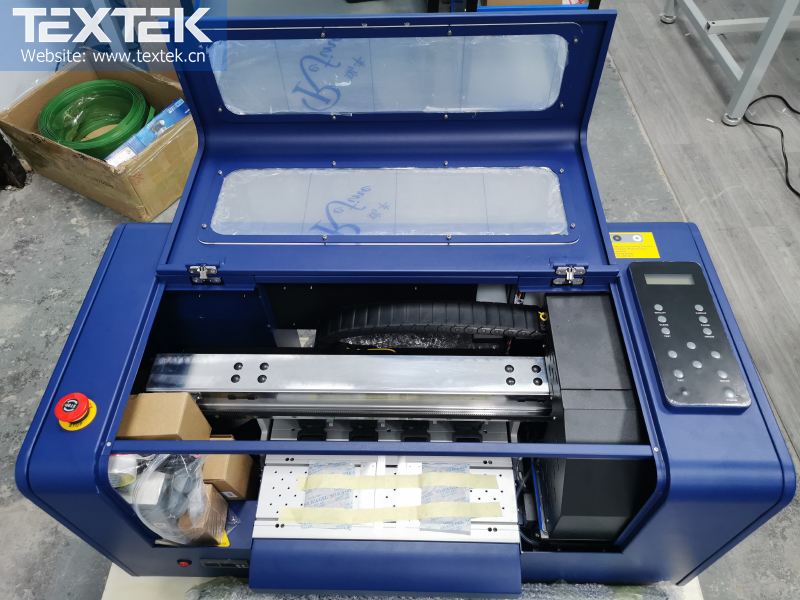

Heating device: front and rear heating

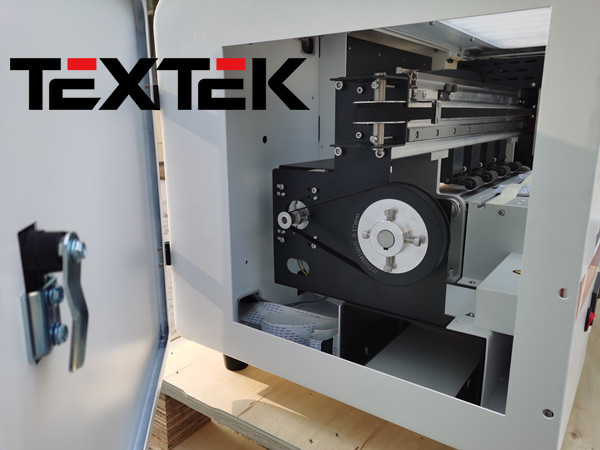

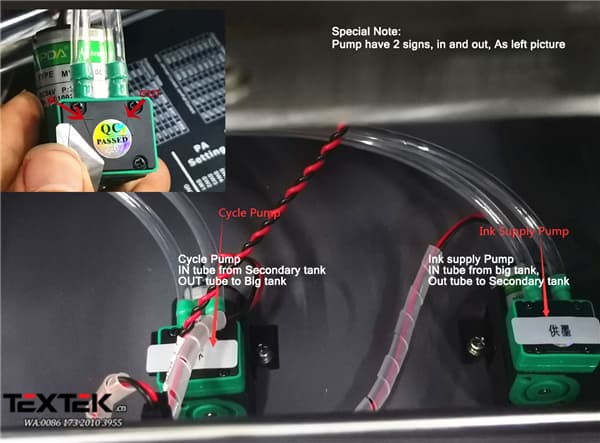

Ink circuit system: automatic ink supply, white ink circulation stirring

Power supply: 110V/220V 50-60HZ

Power: 4KW

Working Environment: Temperature 10-38¡æ Humidity 40-70ph

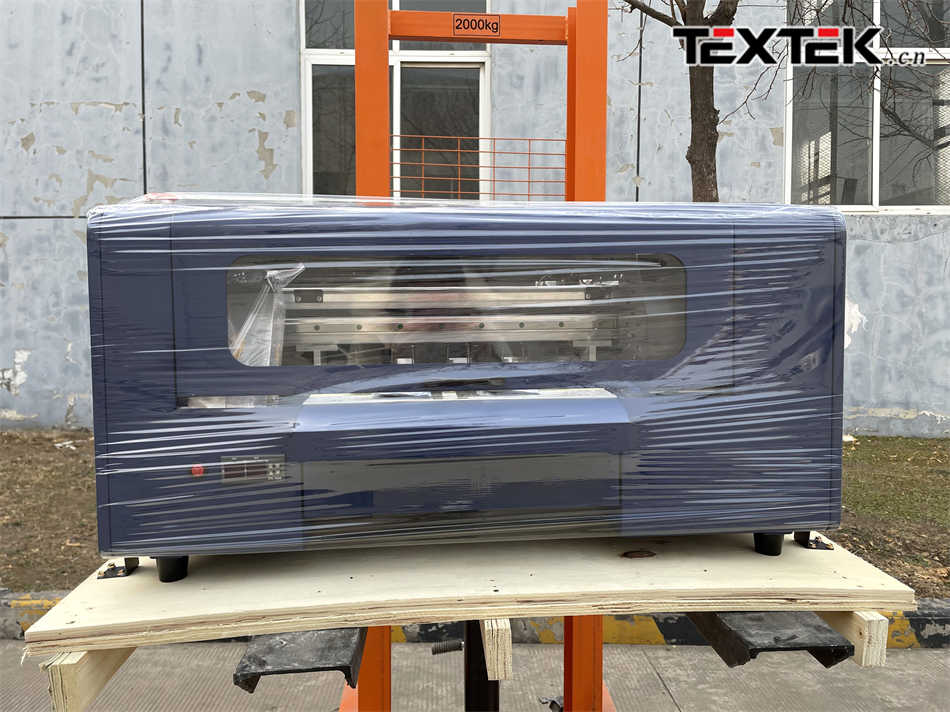

Weight: Machine: 130kg

Packing: 50kg

Use instructions:

1. Preprocess the pattern through image processing software such as PS, and input it into the digital printer software.

2. The printer should make the best match with the consumables and software such as heat transfer film, ink, and ICC to guarantee the printed pattern is colorful and stable.

√ The humidity should be controlled at 50%-60%;

√ The indoor temperature should be controlled at 20-25℃;

√ The rear heating plate should be kept heated to 38-45 degrees.

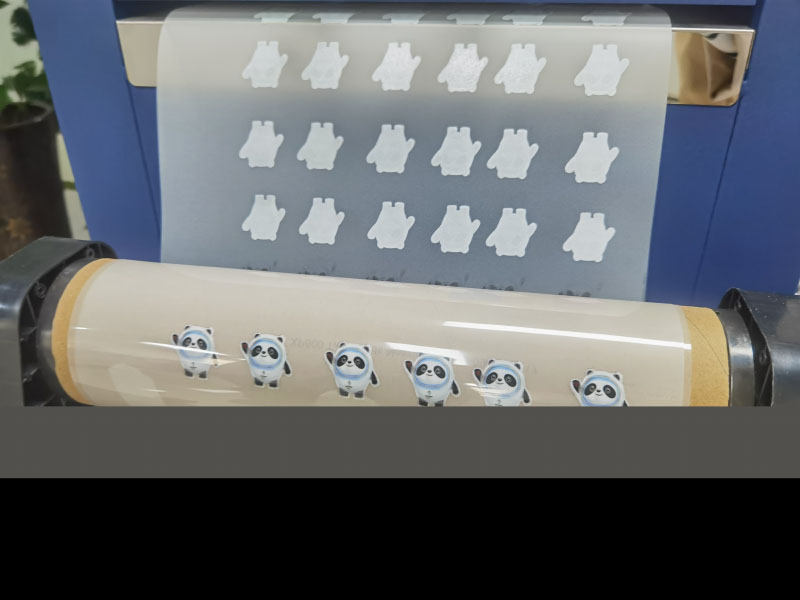

3. After printing the pattern, let the film flow into the automatic powder shaker.

√ Pay attention to climate change due to ink and other reasons. When the temperature is low in winter, the front and rear heating of the printer can be turned on to ensure stable quality;

√ The powder shaker machine’s heating plate is recommended to set at 40-50 degrees.

4. Generally, the baking speed after shaking the powder should match the printing speed. The temperature is best to be warmed first and then heated , and the temperature of the film surface should be controlled between 70 and 90 °C.

5. After the baking is completed, the finished film with pattern should be transferred on the surface of fabric as soon as possible through the heat press machine.

√ Heat press temperature : 140-160℃, adjusted according to the physical properties of powder;

√ Heat press time is 5–10 seconds;

√ Heat press pressure is 5-7KG;

√ It is advisable to match the specific fabric.