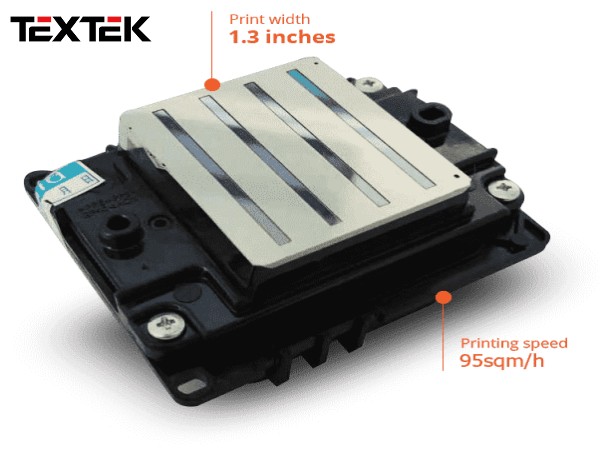

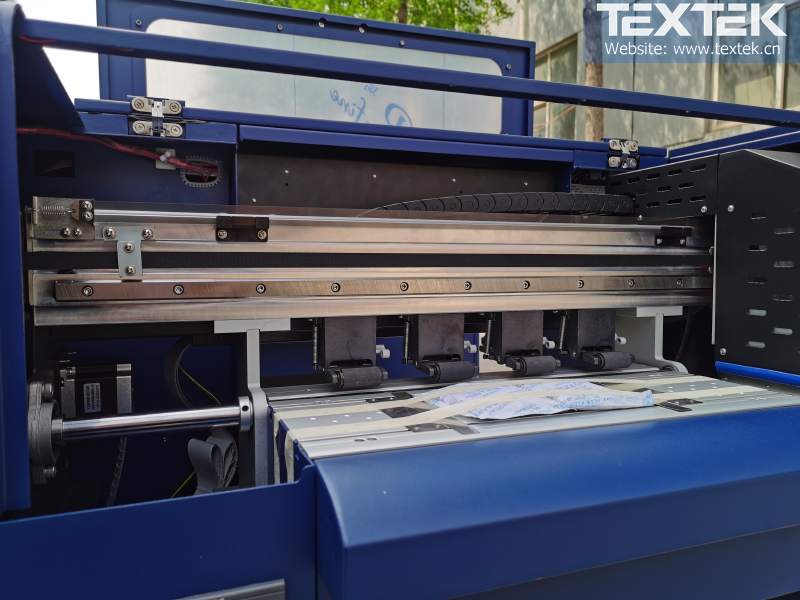

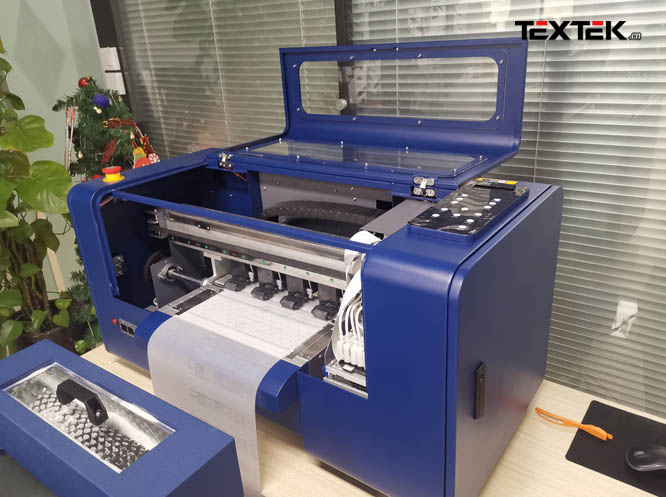

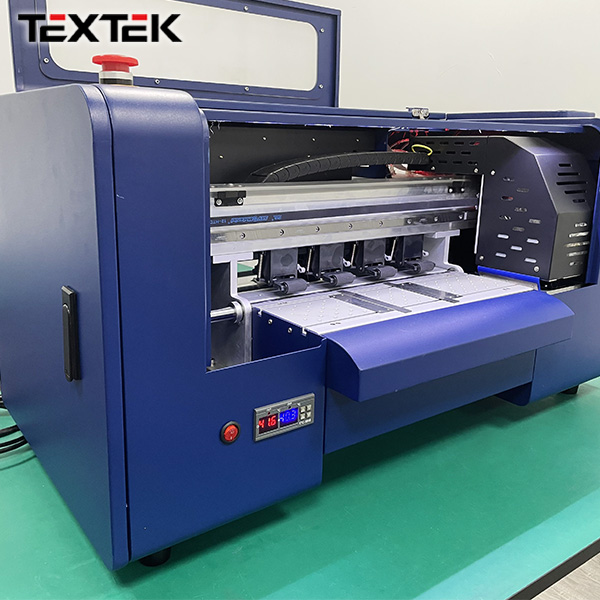

Textek Factory Promotion A3 Dtf T-Shirt Printing Pet Film Printer

Textek Factory Promotion A3 DTF printer printing is much more versatile and can print on a large range of apparel such as nylon, polyester, denim, silk, and of course cotton. Due to the increased number of printing applications, DTF printing is fast becoming one of the most popular methods to print t shirts and apparel.

Textek Factory Promotion A3 Dtf T-Shirt Printing Pet Film Printer

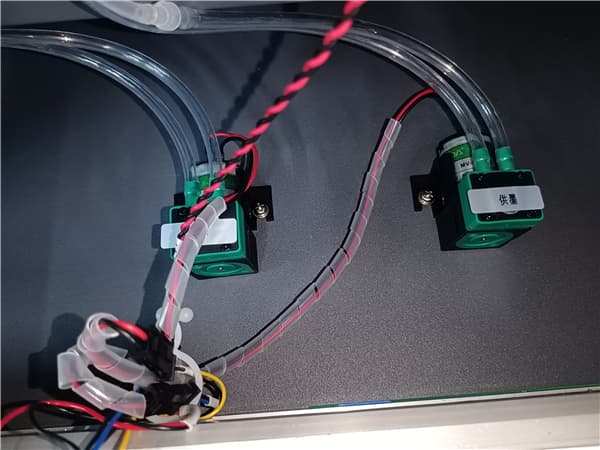

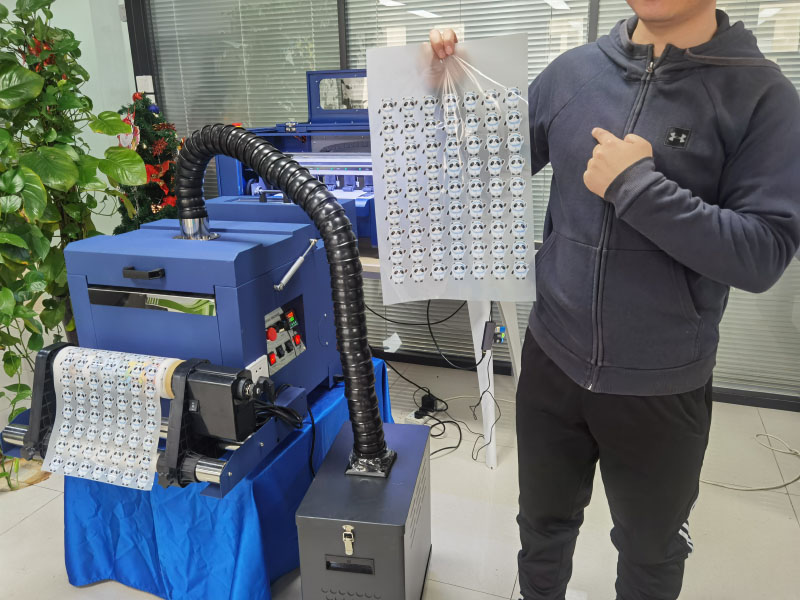

Step 1 – Print on Film

The first step in DTF printing is to create a mirror image of the print design using the white base color. The mirror image will be printed on the PET film and will be used later to press the image onto the garment.

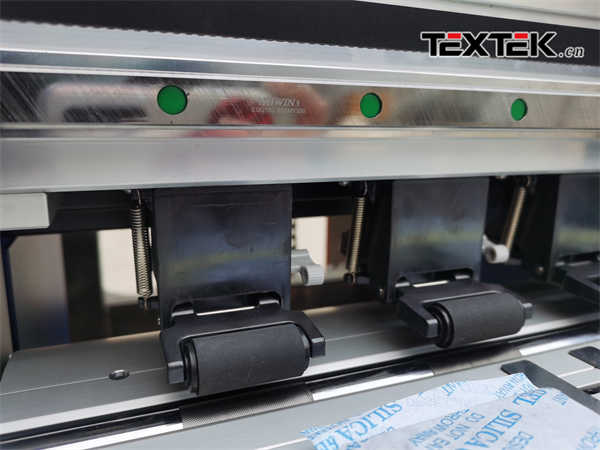

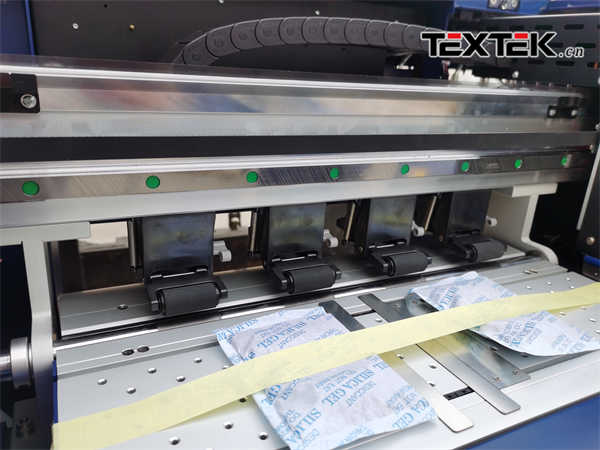

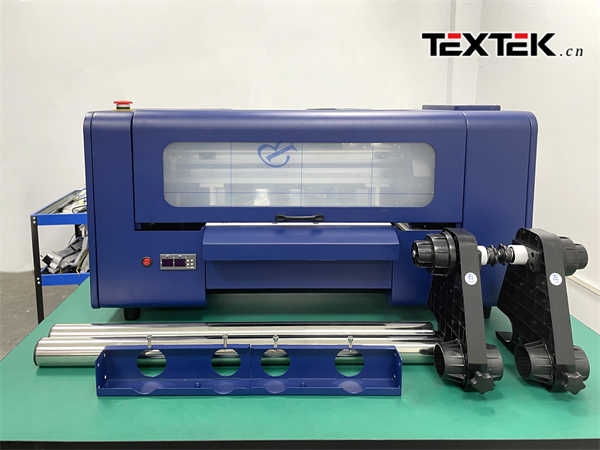

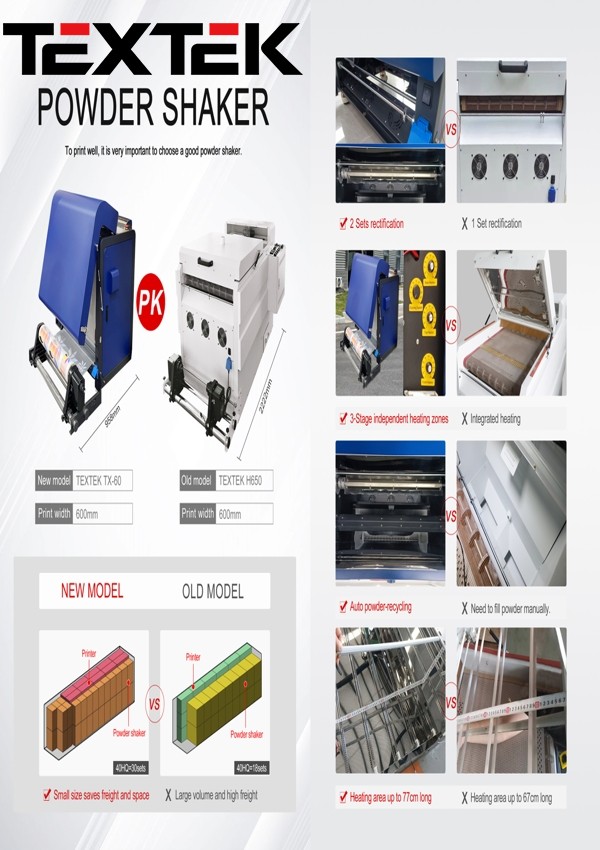

Step 2 – Powder

This step is to apply the hot melt powder to the film printed with the image. This process is done by an automatic powder shaker – evenly spreads the powder and removes excess powder. It is important to use the correct amount of transfer powder as the powder acts as a buffer between the image and the metal.

Step 3 – Melt the Powder

After the transferred powder is applied, it is placed in a curing oven and heated. Heat the powder until it starts to melt. The melted transfer powder acts as a strong adhesive to attach the image to the garment.

Step 4 Transfer

The transfer step occurs when the image and melted transfer powder are placed on the target garment and uniformly pressed using a heat press. This process is a very important step as any failure in the process will cause the image to wrinkle or fall off.

Step 5 Cold Peel

The cold peel step occurs when the image print is peeled from the transfer paper. To maintain the highest level of adhesion, the transfer paper must be removed when the image and garment have cooled to a certain temperature. If the garment is peeled off too early, the image may not fully adhere to the fabric of the garment. Interestingly, the hot melt transfer powder is similar to an amide, which acts as a binder between the ink color and clothing fibers.

Step 6 Post Press

Textek likes to add a step 6 when using the DTF printing method. We’ve added a step 6 to ensure our customers DFT printed t-shirts and apparel images will last a long time and outperform the competition in both wash and user wear.

Our step 6 involves the final iron, where we heat iron the garment for 8-10 seconds. We think the second heat helps strengthen the bond between the ink and the fibers.