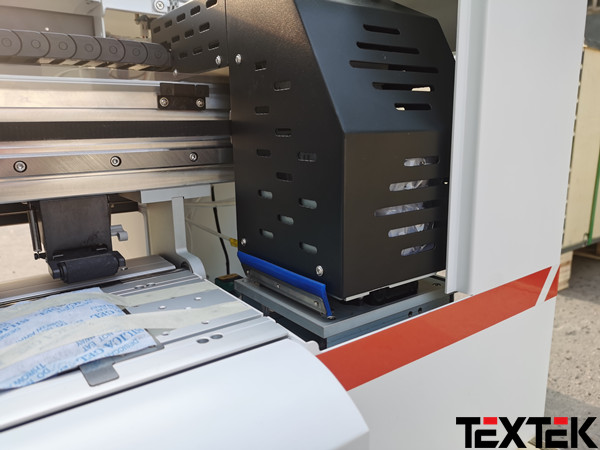

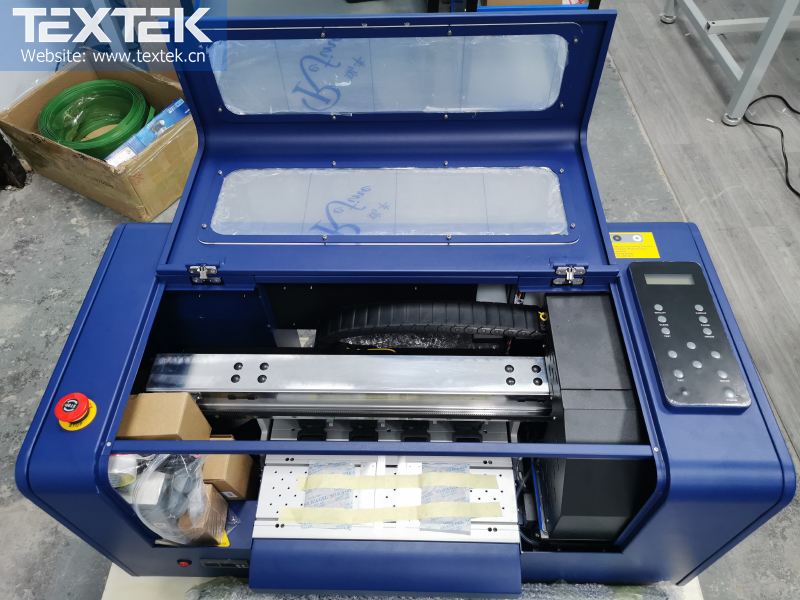

Nozzle blockage is the main factor affecting the product quality and yield of white ink heat transfer printers. Once the nozzle is clogged, there may be color bars, ink breaks, and printing color lines. Therefore, we need to understand the reasons for the blockage of the nozzles in order to better understand the ink output of the white ink heat transfer printer and improve the quality of the printed images. There are three main reasons for the blockage of the nozzle. Today, Textek will give you a detailed explanation, hoping to help you.

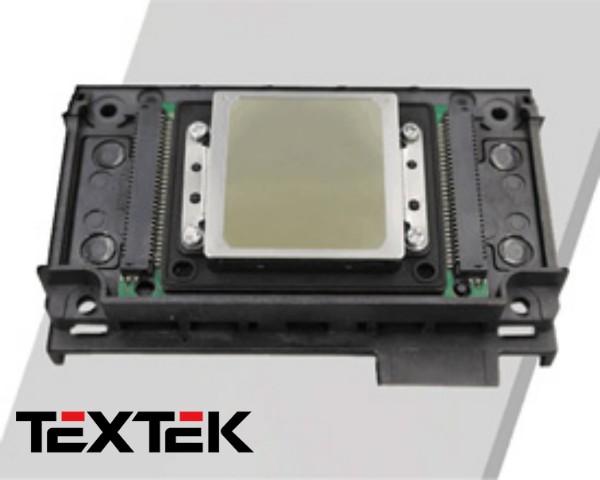

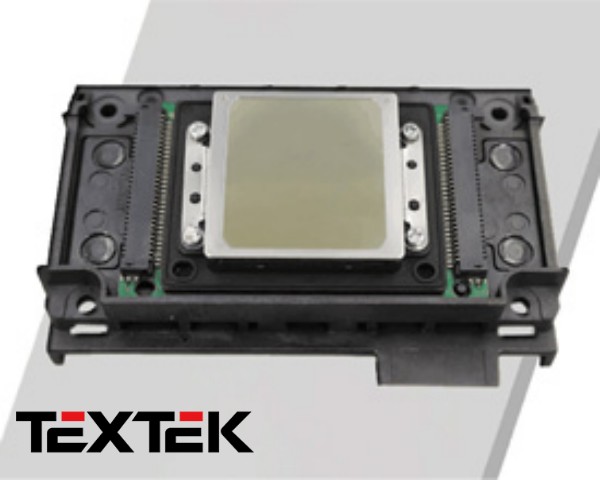

1. The piezoelectric crystal is damaged: the print head cannot eject ink. Piezo heads are typically available for about a year and may be less than a year in a factory with a lot of work.

2. Fatigue damage of piezoelectric crystal: The phenomenon is that the nozzle sometimes inks ink, and sometimes the ink cannot be ejected, especially when the inkjet volume is large, the phenomenon of “clogging” is obvious. At this time, the best method is to replace a new nozzle.

3. Nozzle blocking nozzle: This is the most common blocking method. Because the solvent in the ink must be volatilized into the air to make the picture dry, the ink is a volatile liquid, and it is easy to clear solids in the air. When the nozzle is spraying on the cloth, some ink will remain around it. After this part of the ink is dried in the air, the nozzle will gradually become smaller or even block the nozzle. Fortunately, the nozzle is easy to clean on the outside.

.jpg)