Problems:

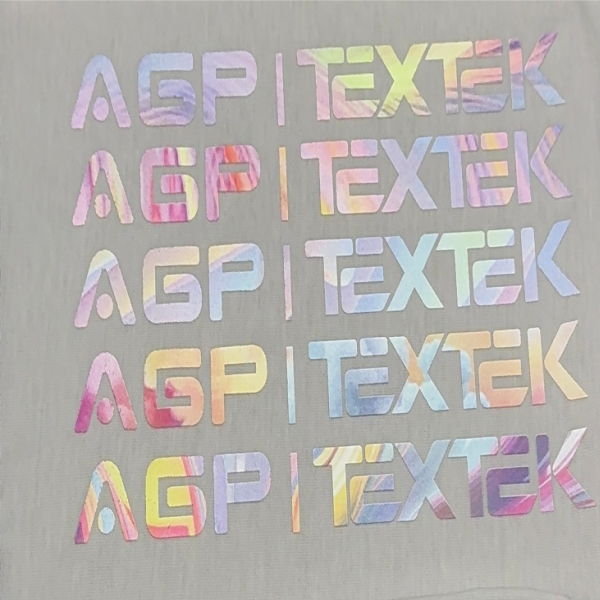

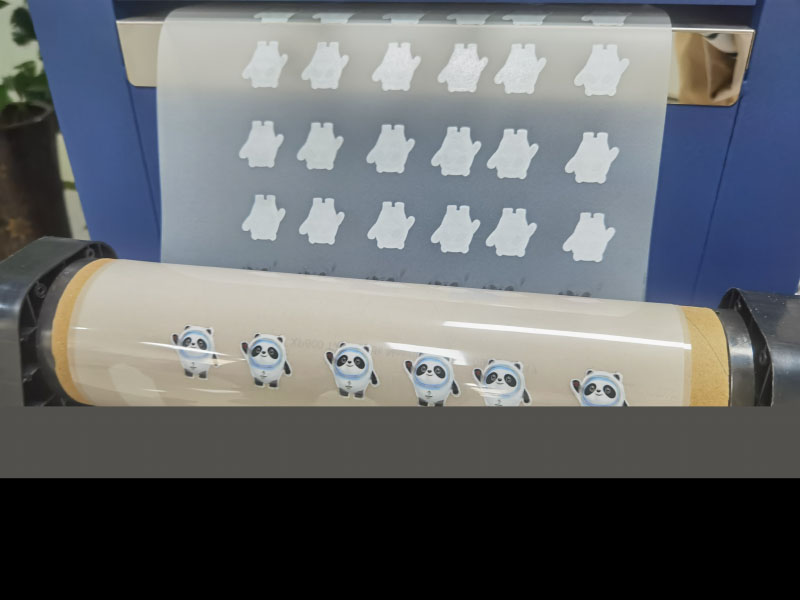

White ink issues are the most common problem and can occur if the white ink is not mixed properly or if the printer is not calibrated properly. As a result, the white ink may look gray or not print at all.

Solution:

To troubleshoot this issue, try mixing the white ink properly and modifying the printer calibration settings.

If white ink is left in the printer for an extended period of time, the whiteness may be uneven due to pigment settling, print holes, diagonal spray, or even clogging. This will affect the print quality. To avoid this, it is vital that you maintain your white ink regularly. Here are some ways to help you solve this problem.

Problems:

White ink issues are the most common problem and can occur if the white ink is not mixed properly or if the printer is not calibrated properly. As a result, the white ink may look gray or not print at all.

Solution:

To troubleshoot this issue, try mixing the white ink properly and modifying the printer calibration settings.

If white ink is left in the printer for an extended period of time, the whiteness may be uneven due to pigment settling, print holes, diagonal spray, or even clogging. This will affect the print quality. To avoid this, it is vital that you maintain your white ink regularly. Here are some ways to help you solve this problem.

Use high quality DTF inks.

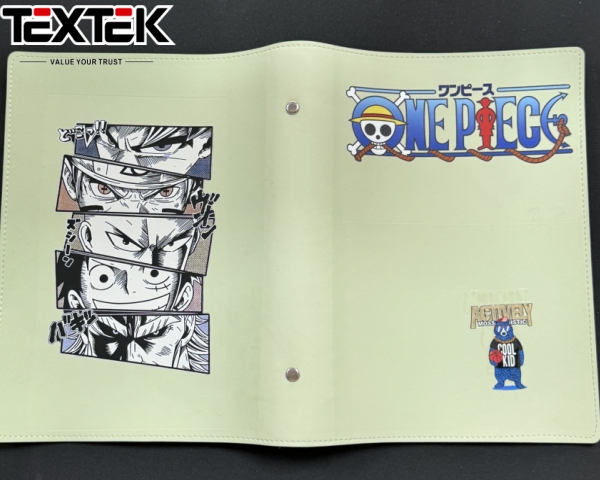

The quality of DTF ink is critical. Not only does it have good wash fastness, whiteness, good hiding power, bright colors, and high concentration, but it also contains as few impurities as possible. Therefore, choosing the best quality DTF ink is the first principle.

Shake the white ink well before filling DTF ink.

Before using white ink, shake the ink bottle up and down. Generally, after 20 times, the stacked ink will be mixed evenly. Because white ink is water-based, if it is left for more than three months, the number of shaking times will double. If left for more than half a month, delamination will begin to occur, so shake well before use for better printing results.

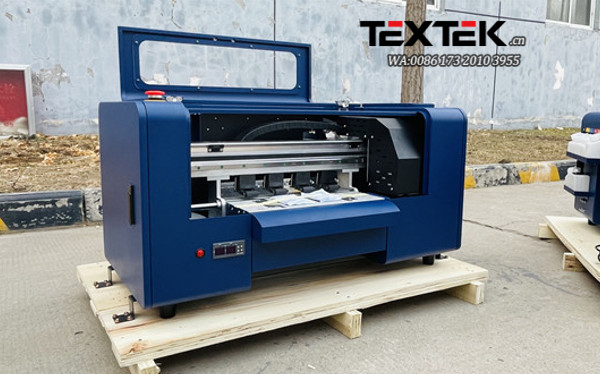

AGP&TEXTEK can provide you with high quality white ink!

Shake the white cartridge once a day

Even if direct-to-film (DTF) printing is not required, shake the DTF white cartridge daily before using the DTF printer.

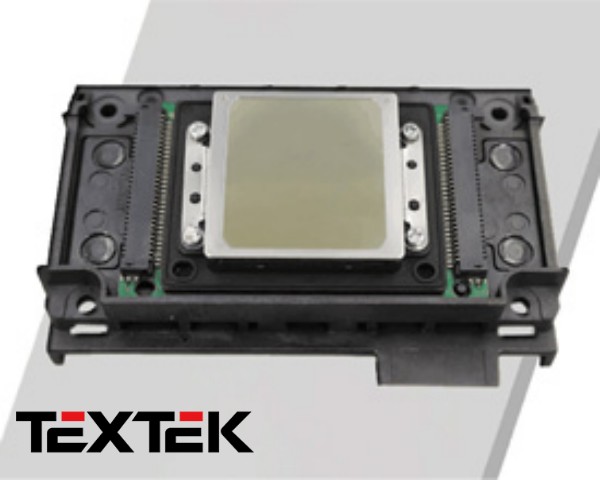

Test the nozzles daily.

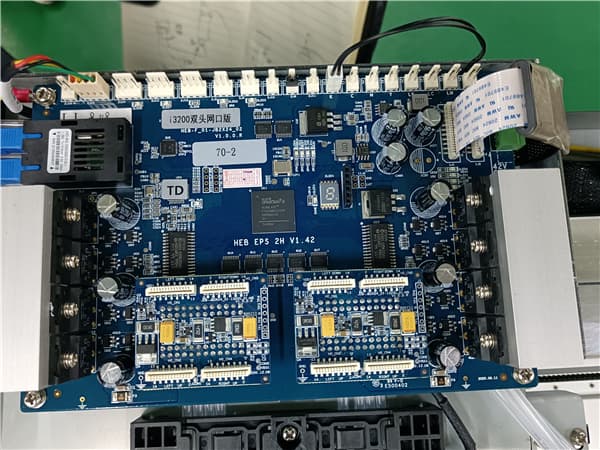

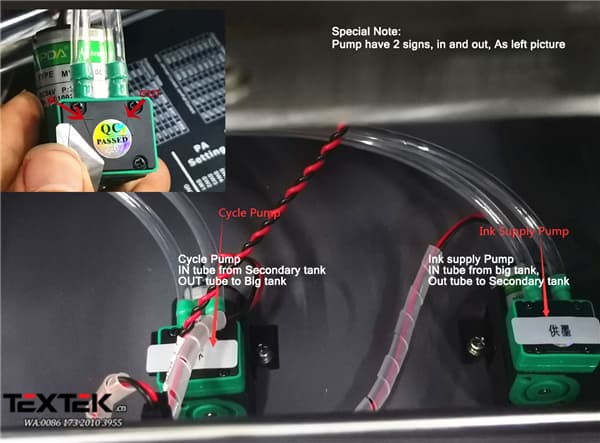

Test the print mesh with the white ink recirculation unit turned on. Print a small pattern (several times) to verify that the printhead is functioning properly. If the print mesh does not work, clean the printheads. So why do you need a print test? If the printhead nozzles do not continuously eject ink, the DTF print white ink has cured in the printhead nozzles.

If the problem is due to improper storage temperature of the DTF ink, then it will also directly affect the effect of the printing, and in serious cases, it will also affect the printhead, resulting in printhead failure. So in terms of ink supplies preservation must be done well.