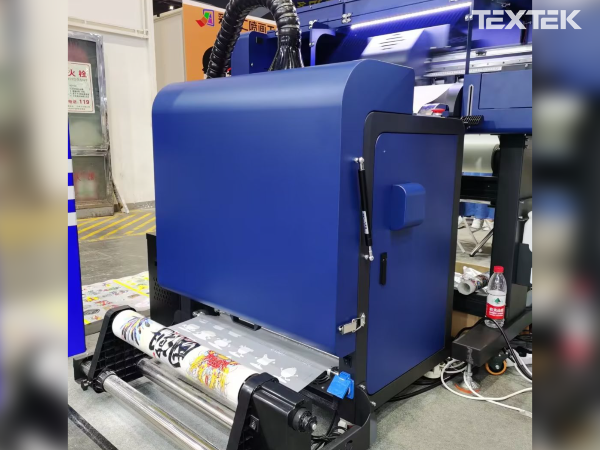

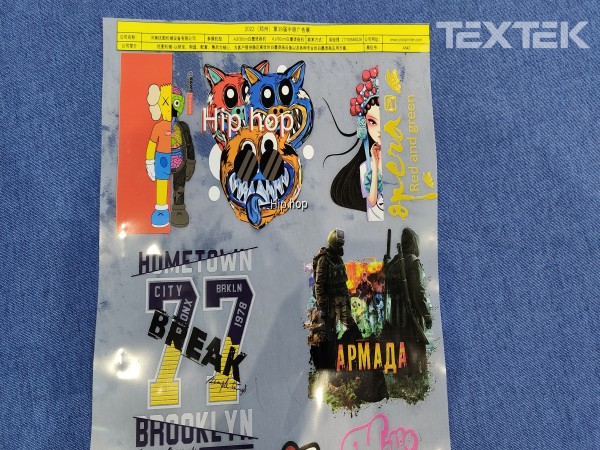

Because the process of white ink heat transfer printer is not complicated, the operation is relatively simple, the required materials are economical and affordable, and it can be widely printed on various substrates, so now the demand for heat transfer printers in various industries is relatively large. The usefulness of the heat transfer printer is transferred to the fabric, which can be used for both industry and civilian use. The heat transfer skills will be endless.

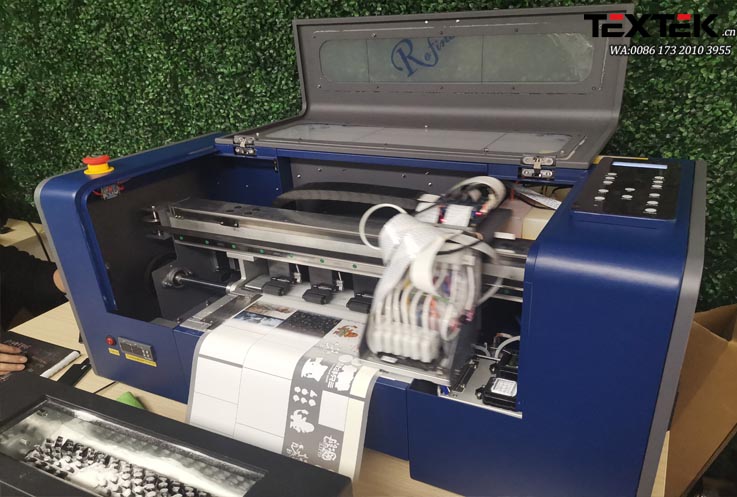

As one of the important equipment for garment printing, white ink heat transfer printer is an indispensable part of the garment printing industry. It is replacing traditional embroidery and screen printing. The operation is simple, the cost and effect are much lower and better than the usual embroidery and multi-color screen printing, and the heat transfer process is becoming a rookie in the clothing printing industry.

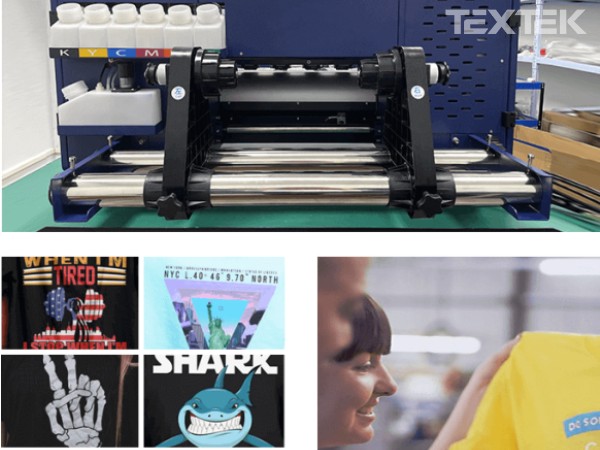

The heat transfer products that we can see everywhere on the street, the heat transfer machine is widely used in the printing industry. Heat transfer machines are used for garment hot stamping and metal photos, knitted T-shirts, denim, plush, toys, shoes, backpacks, all kinds of nylon hats, calendars, hanging scrolls, hanging bags, medals, gold and silver carving photos, Tiles, glass, wood-grained woodblocks… all the contributions of the heat press machine are indispensable.

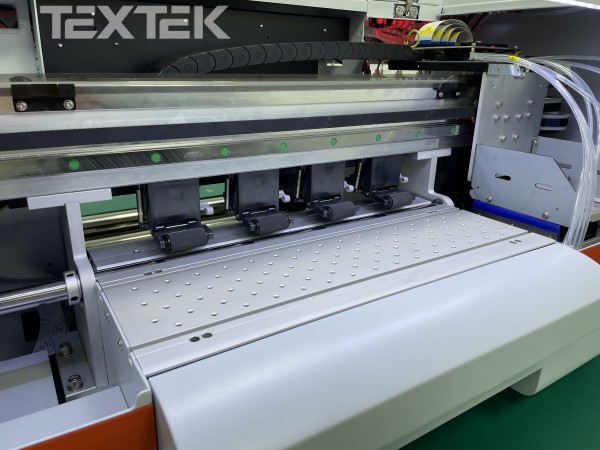

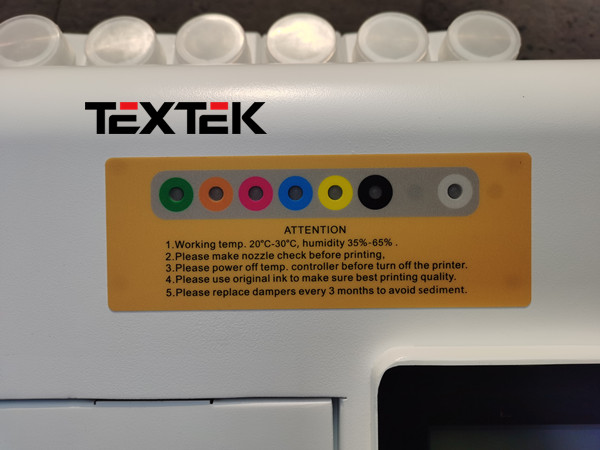

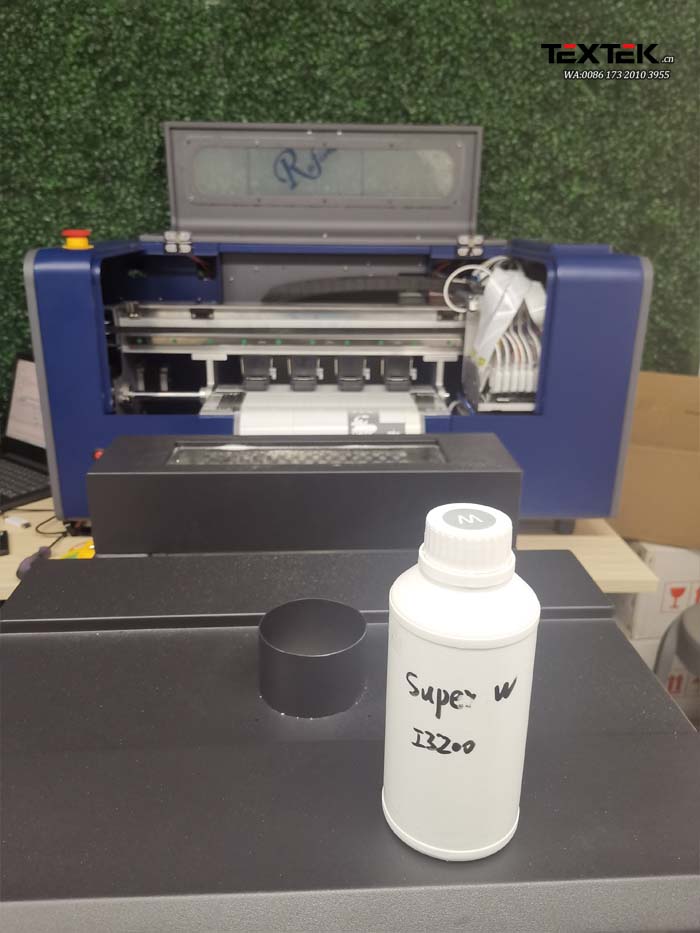

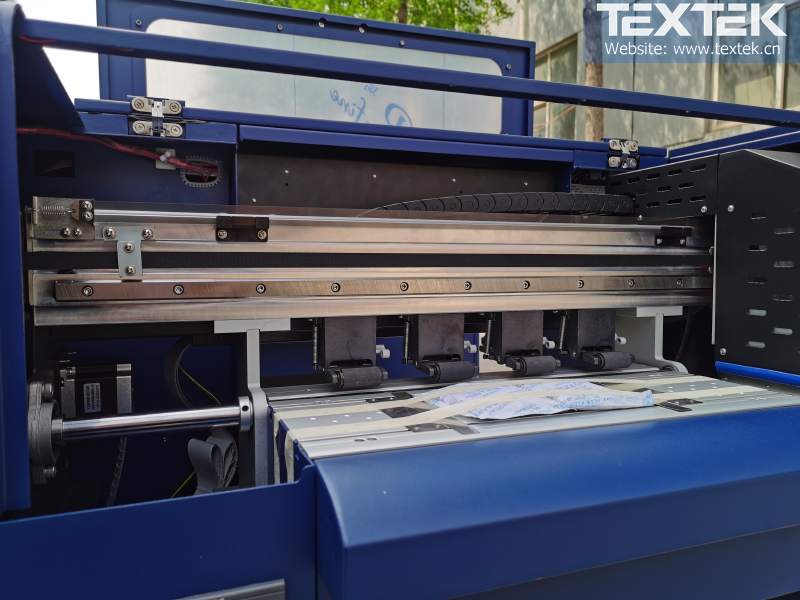

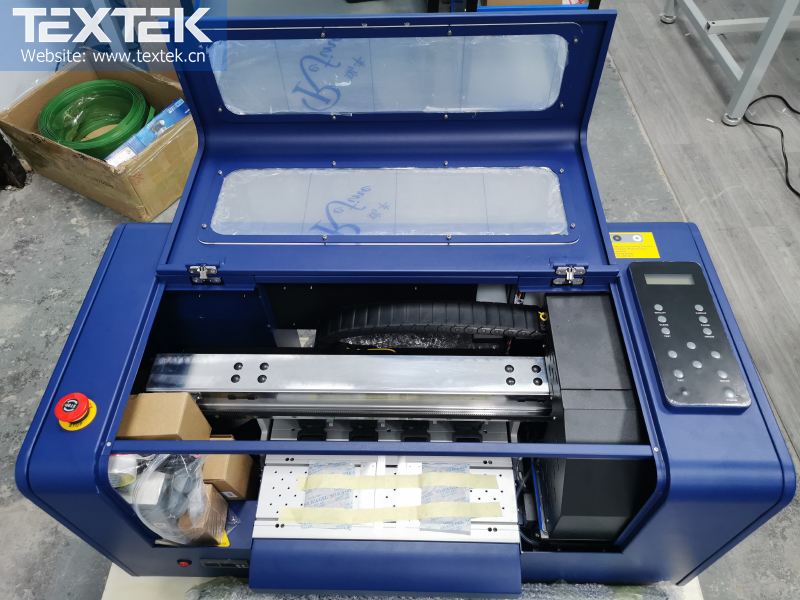

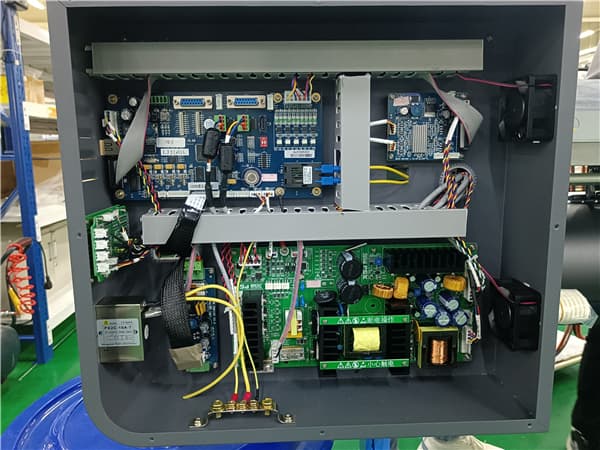

The white ink heat transfer printer generates heat through the heating plate. With a certain pressure, specific temperature and time, the layer and heat setting on the transfer film are pasted to the substrate or penetrated into the substrate, and various heat transfer processes are used. Thermal transfer printing can be done on cotton, linen, chemical fiber and other fabrics, and it can also be heat-treated by screen printing, mucilage, foaming, etc., and can also bake color labels, portrait photos, landscape patterns, etc. The board is especially suitable for making medals, commemorative cards, cultural shirts, etc. It is economical and practical, and the patterns are exquisite.

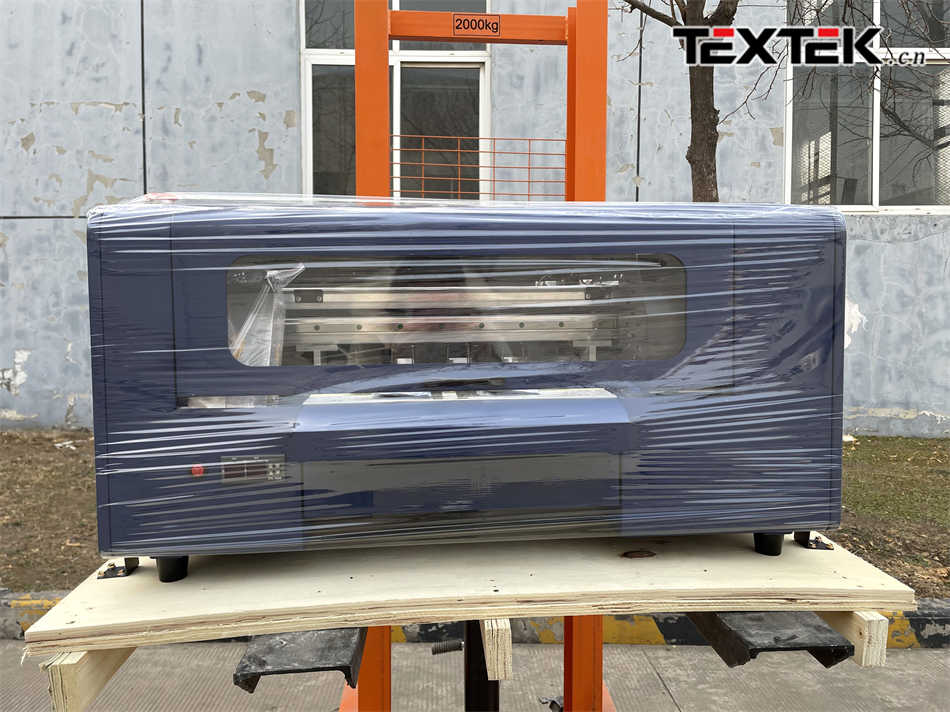

Although the process of printing patterns on a white ink heat transfer printer is relatively simple, a large area of heat transfer that is uniform and does not fall off is a time to test your skills. The transfer interface of heat transfer is very important, that is, the processing skills of heat transfer. If the temperature is too low, it cannot be attached. If the temperature is too high, the pattern will bloom or burn. Therefore, it is very important to choose which brand of white ink heat transfer printer. TEXTEK DTF Printer, we not only provide customers with reasonable heat transfer solutions and comprehensive technical support, but also provide high-quality after-sales service!