In the daily production of dtf printers. If the dtf printer printing and processing printing machine continuously supplies the ink tanks to produce air bubbles, it will affect the print output effect, and waste a lot of ink and printing film. If you encounter problems, you should solve the problem immediately. What is the cause of the dtf printer ink tanks? Will there be bubbles? Now let’s learn this together.

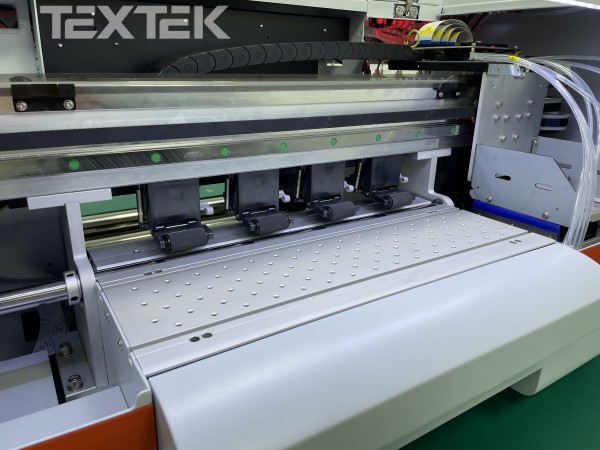

1. The continuous supply of ink tanks has a bubble failure phenomenon. The external ink tanks have been placed in a low position for a long time, and now the ink supply pipeline does not enter the ink. Most of the above failures are caused by the foaming of the ink in the ink tank. After the ink supply system has been used for half a year, a small amount of tiny air bubbles from the ink and a small amount of air bubbles from the heat transfer printing processing printing printer nozzle enter the printing ink tank. Accumulation, the heat transfer printer will gradually foam the ink. If this problem occurs, it can be solved by extracting the foam and replacing it with normal ink.

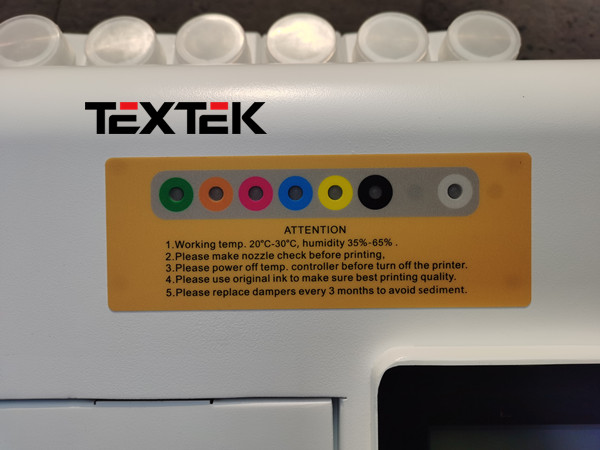

2. There is always a lack of color during printing. At the beginning of the printing test, it is normal. After printing a few pages, there is a disconnection phenomenon. After the printing ink cart is returned, the printer will perform a natural cleaning. Please perform a nozzle check to print the test line.

3. The cleaning command should be cleaned many times before printing, and the cleaning and printing test line can be repeated 3 times until the test line is completely normal. Then print the four-color or six-color color patch test chart. The color patch test chart must be printed 3-5 consecutively. At the same time, observe whether the printer works normally. If there is any abnormality in the printing, the above steps can be repeated.