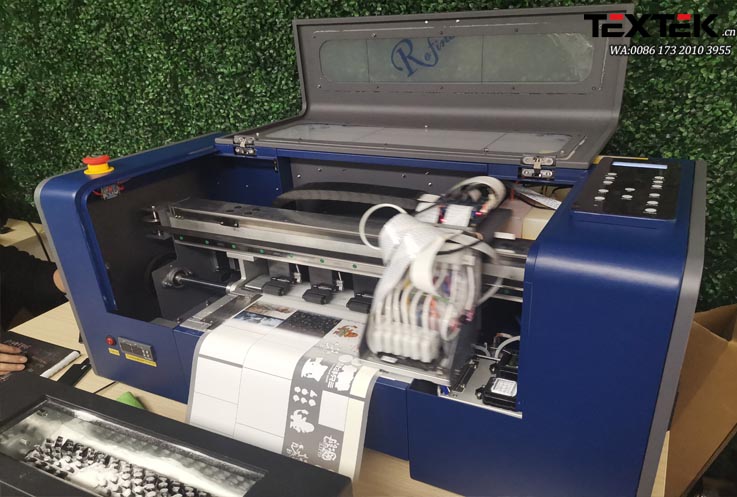

Can the quality of the dtf printer ink really determines the quality of the printed image? Yes, the quality of the ink can directly determine the quality of the printed image, as well as the service life of the nozzle. At present, the manufacture of heat transfer printing machine ink on the market is very complicated, whether it is the original ink or the compatible ink. The correct selection of ink and the correct maintenance of the nozzle are the problems that every user of the heat transfer printing machine cannot ignore in the use.

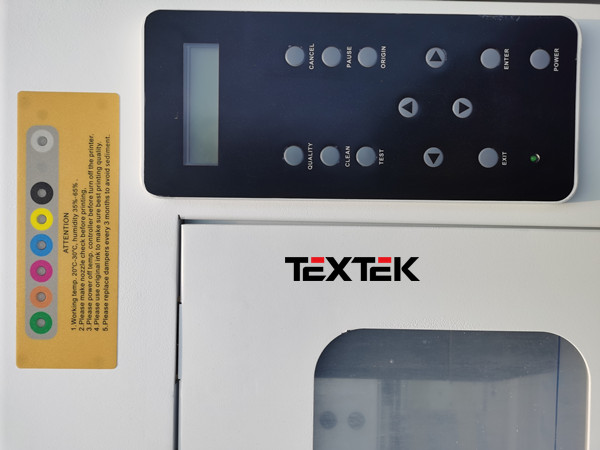

However, when choosing a heat transfer printing machine and dtf printer ink, users must pay attention to choosing high-quality original ink from the manufacturer. Here, Textek mainly introduces the requirements for the use and selection of ink. We know that in order to achieve the effect of printing patterns, the ink we need to purchase must meet the requirements of good weather resistance, water resistance, light resistance, acid and alkali resistance, and colorfastness. The quality of the ink must be smooth and not blocked to be called high-quality ink.

Different print heads must be matched with appropriate ink, otherwise the structure may be damaged, the effect of the printed image will be affected, and the print head may be damaged. It will inevitably bring about problems such as uneven ink concentration of various colors, chromatic aberration in the sprayed pictures, and easy plugging of the white ink heat transfer printing machine. Although today’s piezoelectric printheads have very good compatibility with inks, at the same time, different types of inks also have certain requirements for different inkjet printing media. Ink is one of the most important consumables for white ink heat transfer printing machines. Choosing a high-quality ink manufacturer can reduce more troubles and problems in your printing process.