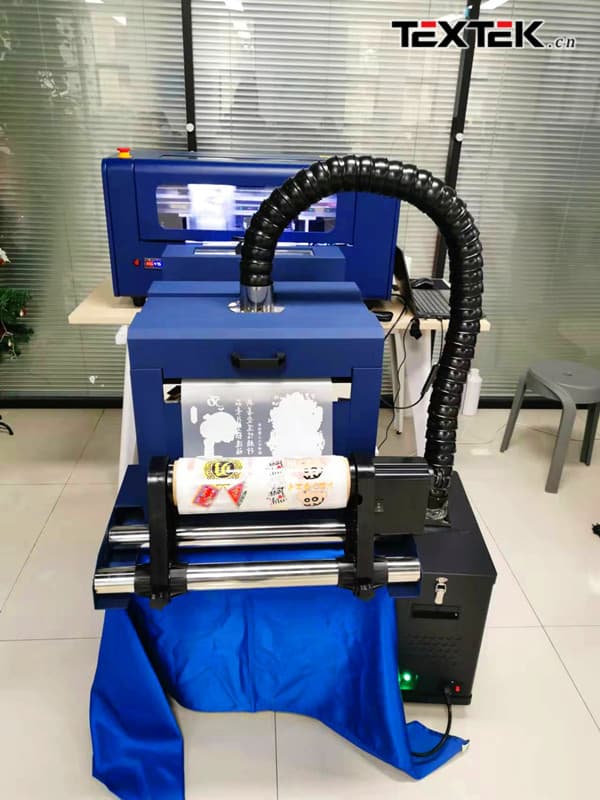

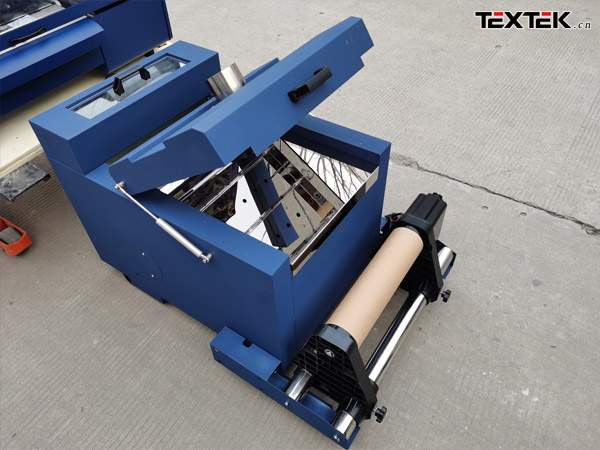

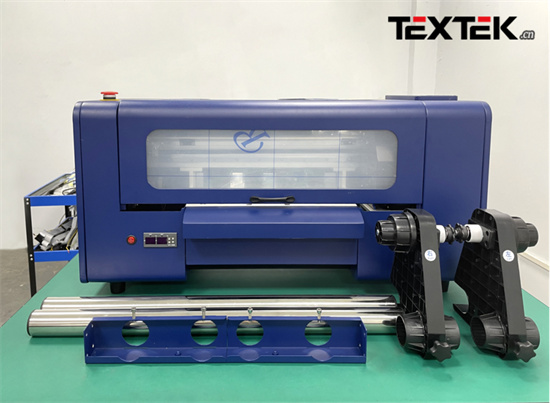

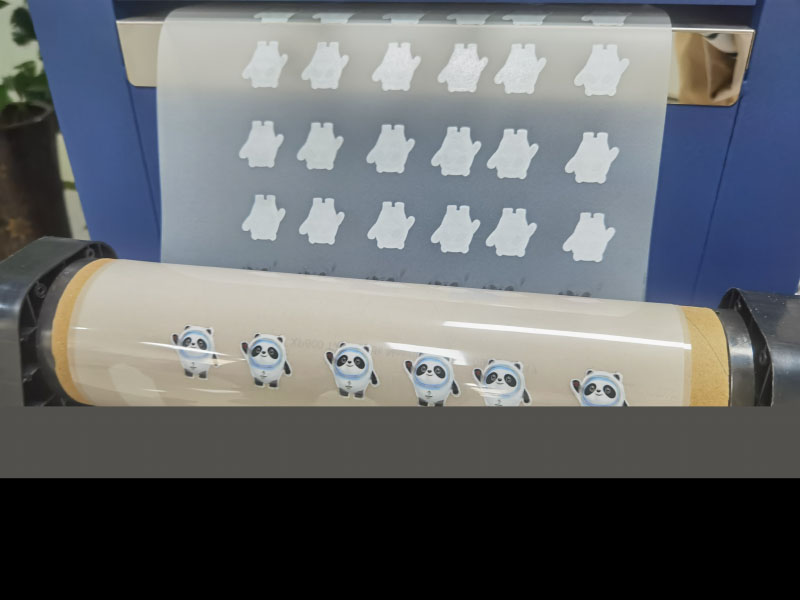

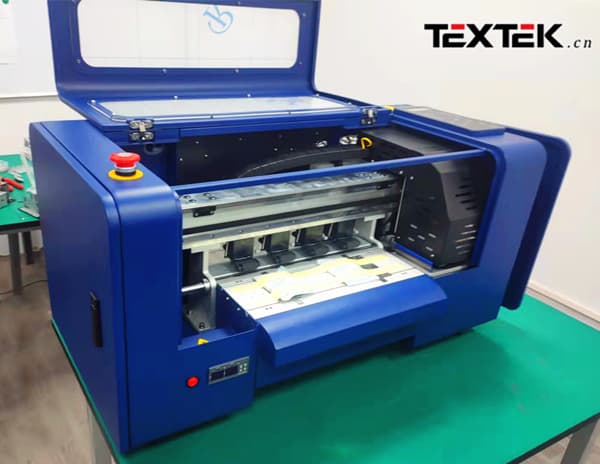

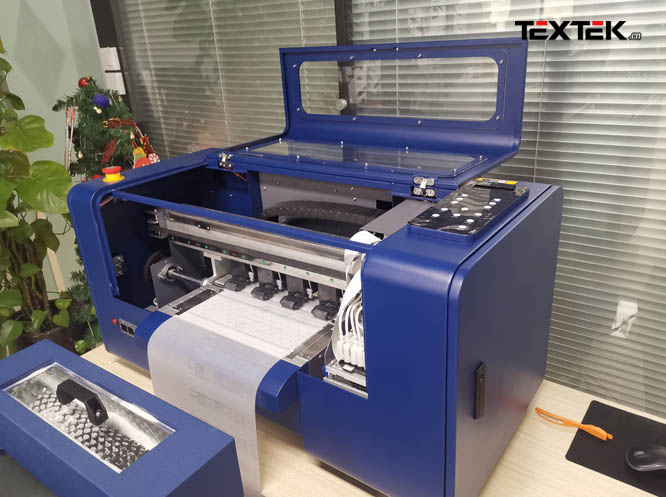

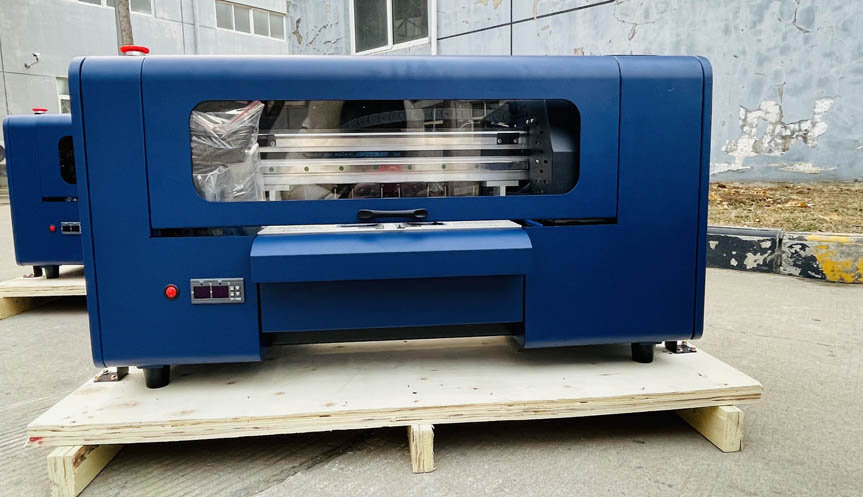

Textile Printer factory,2022 Hot Product DTF printer with 2Pcs XP600 print heads and shaking machine,Automatically complete the process of printing and heating

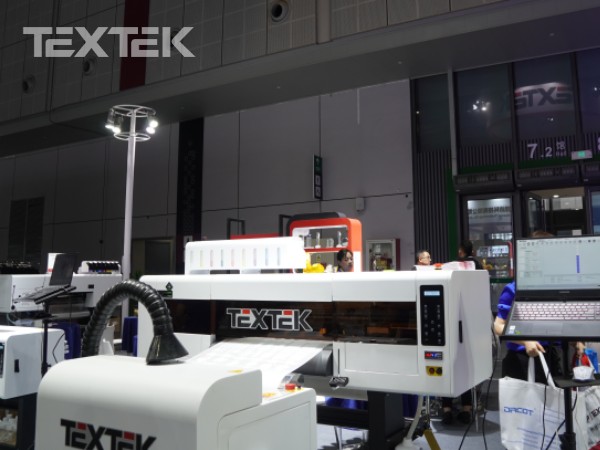

We are the source factory, which is a complete one-stop service from independent research and development to independent processing of raw materials, production, assembly and delivery to after-sales;

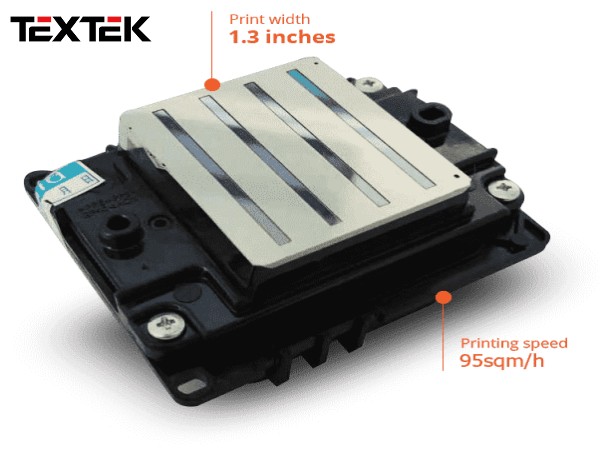

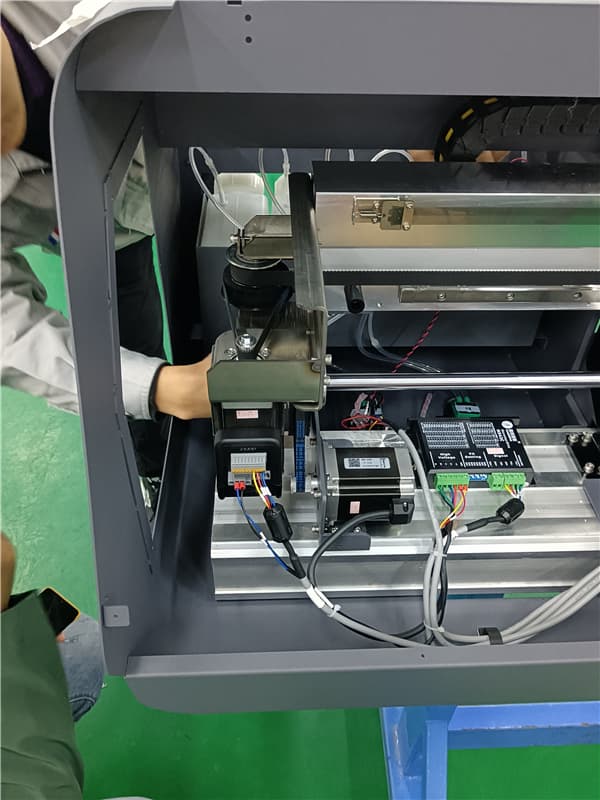

The self-developed patented printing algorithm ensures the accuracy of the midpoint of high-speed printing through point compensation, and provides the printing accuracy of the map;

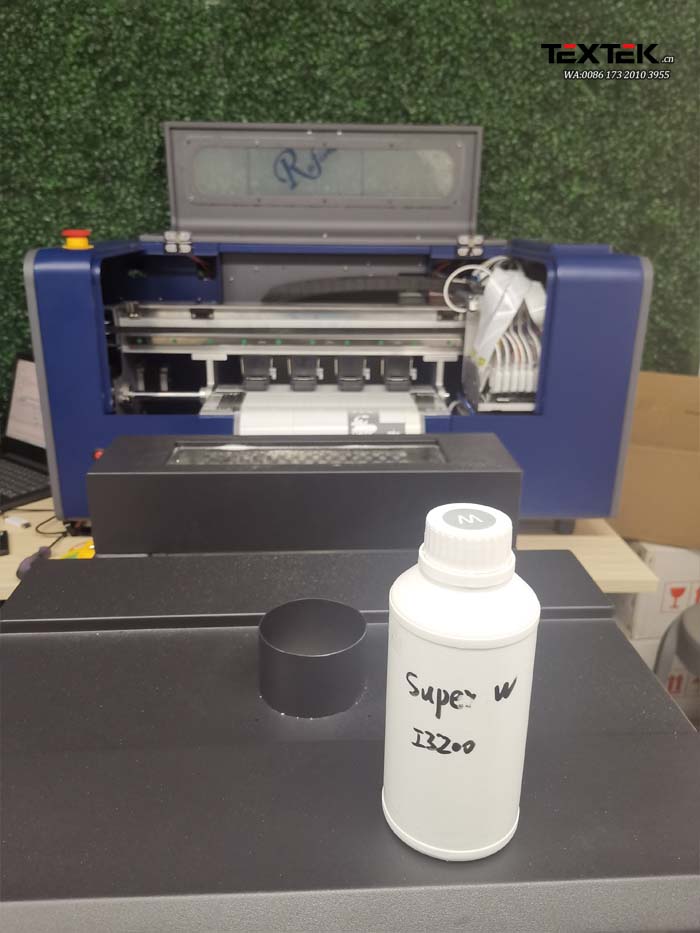

The all-in-one duster has an automatic working mode, which automatically completes the process of printing and heating.

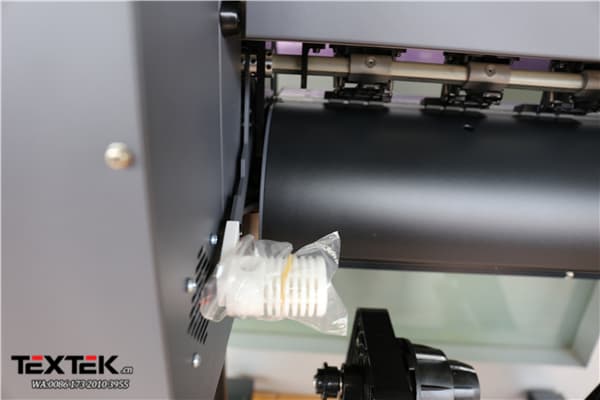

Maintenance of the print head

1.Shut down in accordance with the prescribed procedures: first turn off the control software when shutting down, and then turn off the main power switch to ensure that the carriage returns to its normal position, to ensure that the print heads and ink caps are completely matched to avoid clogging.

2.When replacing the ink cap, it is recommended to use the original ink cap, otherwise the ink cap may deform and cause nozzle blocking, ink missing, incomplete ink extraction, and unclean ink extraction. If the printer is not used for more than three days, please clean the ink cap and waste ink tube with cleaning fluid to prevent it from drying and clogging.

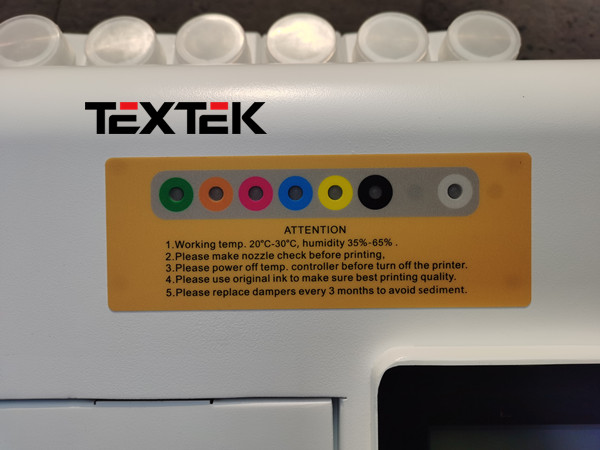

3.It is recommended that you use the original ink from the original factory. It is strictly forbidden to mix two different brands of ink, so as to avoid chemical reaction, block the nozzle, and affect the quality of the printing.

4.Do not plug or unplug the printer cable when power is on to avoid damage to the motherboard.

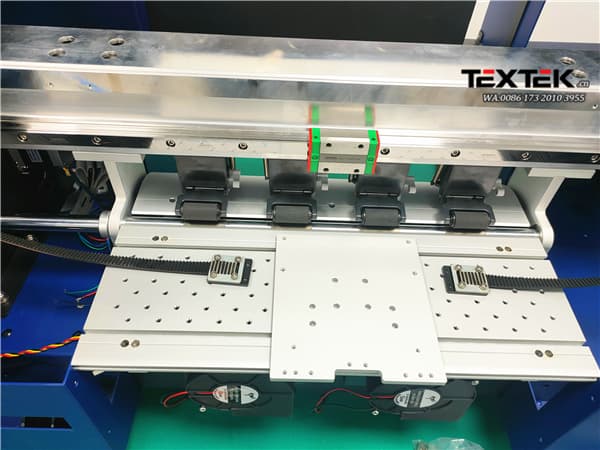

5.The machine is a high-speed printer, please be sure to connect the ground wire: ①When the air is dry, the static electricity problem cannot be ignored. ②When using some inferior materials with strong static electricity, static electricity may cause damage to the machine’s electronic originals and print heads. Static electricity will also cause ink flying during printing. It is forbidden to operate the print heads with power.

6.Because this equipment is a precision printing device, it is recommended to equip a voltage stabilizer with a power of about 2000W.

7.Keep the ambient temperature at 15℃-30℃, humidity 35%-65%, keep the working environment clean and avoid dust

8.Wiper: Clean the ink wiper regularly to prevent ink solidification from causing damage to the print head.

9.Working platform: Keep the platform surface free of dust, ink, and debris to prevent the print heads from being scratched.

10.Ink tank: close the lid immediately after filling the ink to prevent dust from entering.

11.Weekly inspection:Do daily cleaning and exhaust maintenance of the print head every week. Once a week, pour the cleaning fluid into the ink cap to soak the print head surface.