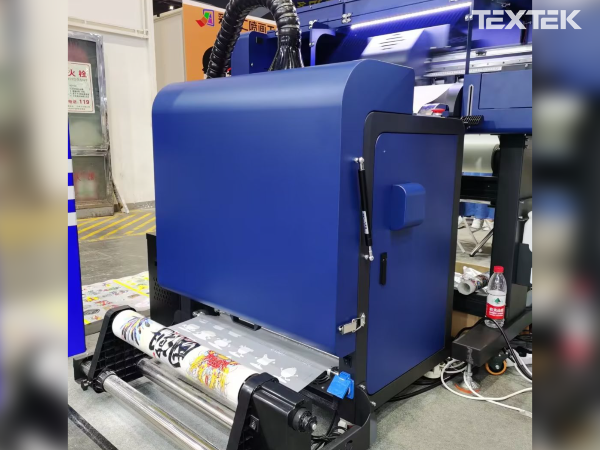

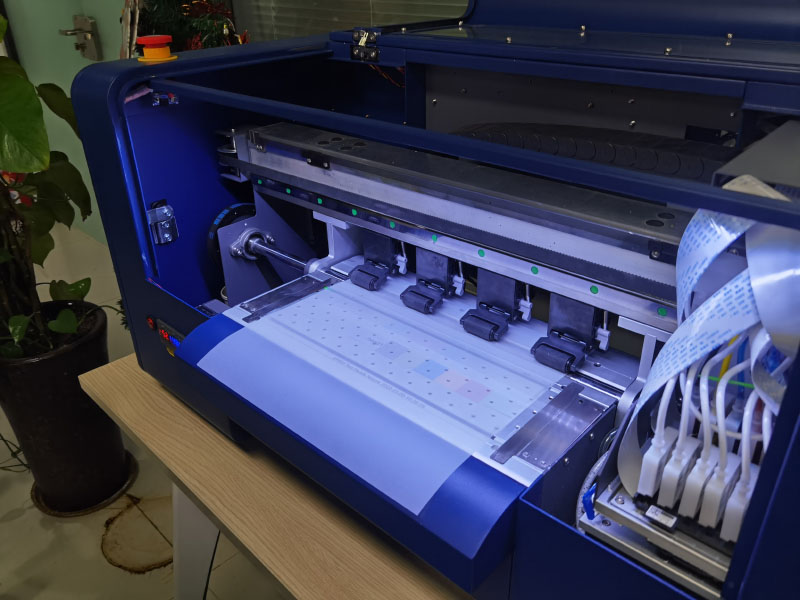

Although the most important spare parts of dtf printers are nozzles, the maintenance of other parts is also a part that cannot be ignored. For example, the guide rail of the heat press machine is a very important accessory. The role of the guide rail of the dtf machine is to print the track of the moving carriage. Only when the track is intact and there is no dirt can the printing task run normally.

The maintenance of the guide rails of dtf printing machine equipment is a step-by-step process. After turning on the power of the printing machine, let the carriage go back and forth for several cycles. If there is dirt in the guide rail sliders, the dirt will remain on the guide rails. After repeating several times, then wipe off the dirt with a paper towel or non-woven cloth. If it is still not clean, use alcohol to scrub. After scrubbing, the printing task cannot be performed immediately, and you need to wait a few minutes for the alcohol to evaporate before printing.

After the dtf printer finishes printing every day, it should clean and maintain the guide rails. Use a clean cloth or non-woven cloth dipped in alcohol to wipe off the dirt on the guide rails, and then wipe the guide rails with a dry non-woven cloth or paper towel dipped in a little oil or lubricating oil. After wiping the smudges on the guide rails, make sure that the guide rails are free of any smudges that affect the movement of the carriage to ensure the next printing task.