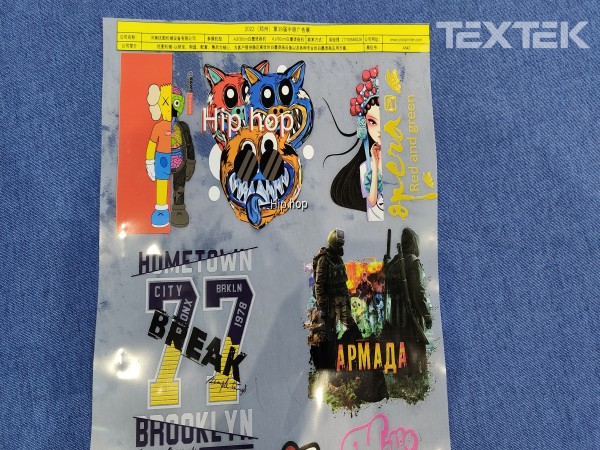

There are three main types of direct to film printer consumables, dtf ink, dtf film and hot melt powder. The most important of these is dtf ink, because bad dtf ink not only cannot print out full-color product patterns, but also leads to clogging of the nozzles and even damage to the nozzles. So we will recommend customers and friends to buy high-quality ink with high fluency.

Ink viscosity that is too high or too low can cause malfunctions. If the viscosity of the ink is too high, the fluidity of the ink is poor, and the amount of ink ejected by the nozzle per unit time is not enough. The viscosity of the ink is too low, that is, too thin, it is easy to inhale air when the piezoelectric crystal in the nozzle hole is drawn back, and the ink cannot be sucked in, so what is ejected is air, both of which will cause the ink to not come out of the nozzle.

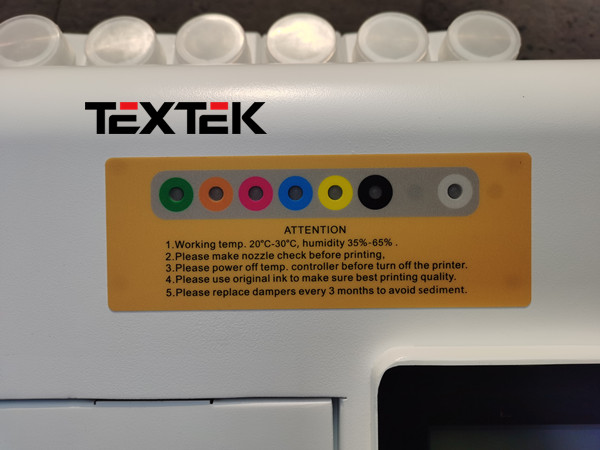

In this regard, TEXTEK technical engineers often ask customers that the environment for storing ink is very important. It is better to place the ink in the environment where the ink is used before use, because the viscosity of the ink will be high when placed at low temperature, and The viscosity will become very low at high temperature, and the viscosity difference is very large. Once the inks with large viscosity differences are mixed together, the ink will not be ejected.