Reasons for DTF Oil, water back, bubbling, this series of problems

They are closely related to the machine process, materials, and environment.

1. Process factors

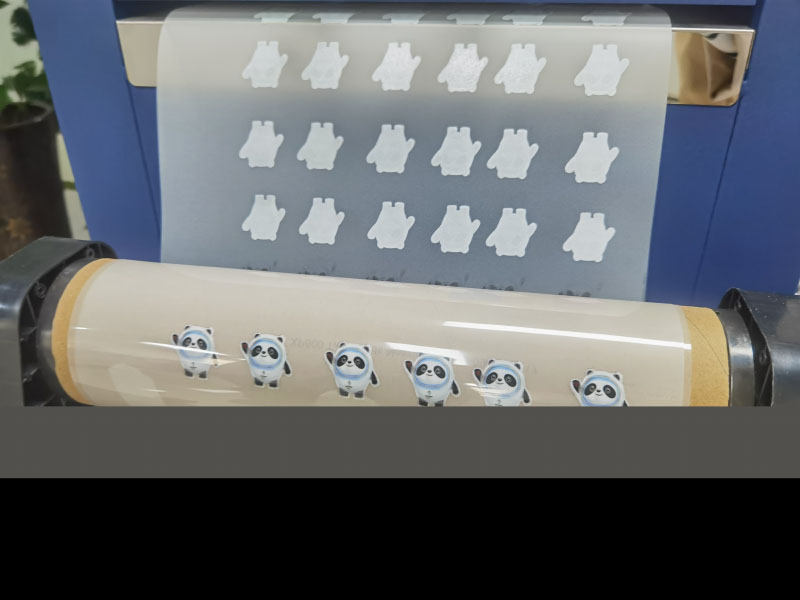

After the heat press machine prints the white ink part, it will enter the powder spreading state. At this time, about 50%-60% of the water is still trapped in the white ink layer. Then the film will be sent to the constant temperature drying area of 135 to 140 degrees. The glue powder will quickly melt into a film, sealing the white ink. At this time, there is still 30%-40% of water in the white ink, which is sealed between the film and the glue powder by this layer of the glue powder.

Although the surface of the finished film looks dry, it is just an illusion. When the remaining water in it is condensed, water droplets will be produced. This is an important cause of moisture and water back on the surface of the finished film.

How to avoid it?

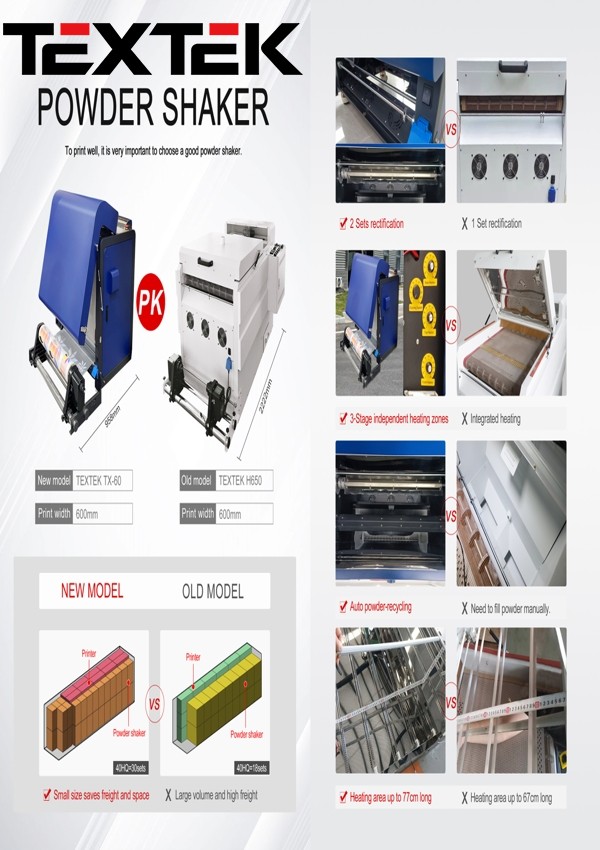

If the manufacturer of white ink heat press equipment can divide the drying area into three stages (i.e. three-stage drying), this problem can be avoided with the greatest probability.

After the white ink heat transfer that is evenly sprinkled with hot melt powder enters the dryer, the initial temperature will be controlled at 110 degrees. At this time, the water begins to boil and the water vapor evaporates, but the hot melt adhesive powder does not melt over a large area, and the water in the white ink will be dried quickly; the temperature of the second stage is controlled between 120-130 degrees to dry the glycerin and various oily substances in the middle; the temperature of the third stage can reach 140-150 degrees. At this time, the hot melt adhesive powder is dried as quickly as possible, allowing it to melt into a film, closely fit the pattern, and ensure the firmness of the pattern.

Material factors

The influence of materials on the quality of white ink heat transfer is self-evident. It has a huge impact on the color accuracy, detail performance, durability, and even feel of the finished product.

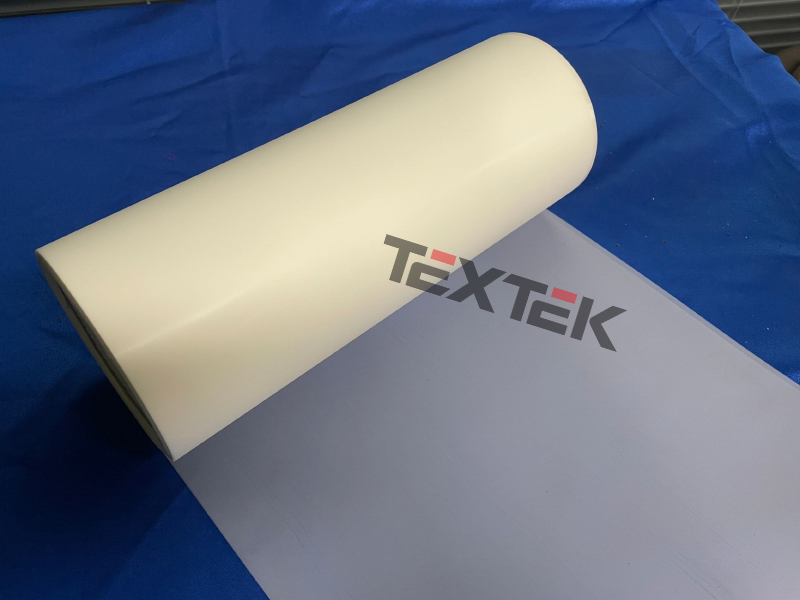

Since the printing film is easy to absorb moisture, when storing the white ink heat transfer printing film, more attention should be paid to moisture-proof.

How to store DTF materials?

The printing film should be put back into the original packaging after each use, and try not to touch the ground and wall. If there is no packaging bag, you can wrap the bottom of the film, seal it and store it in a ventilated and dry place.

Environmental factors

In a humid environment, the printing film is easily damp, causing the ink to condense on the printing film, resulting in the ink droplets not being able to spread evenly and oil return. In addition, a humid environment can easily cause the nozzle of the white ink heat transfer printer to be blocked, thereby affecting the printing effect. Therefore, to maintain the quality and effect of white ink heat transfer, it is necessary to avoid using the machine in a humid environment.

How to effectively avoid oil return of white ink heat transfer?

1. Open windows for ventilation frequently

Open windows for ventilation frequently to keep the indoor air flowing and avoid humid air from being trapped indoors, thereby reducing the chance of white ink heat transfer getting damp.

2. Use a dehumidifier

In humid seasons or areas, a dehumidifier can be used to reduce indoor humidity, thereby reducing the possibility of white ink heat transfer getting damp.

3. Properly control the printing temperature

Excessive printing temperature will cause the ink to evaporate too quickly, and it is easy to form water droplets on the printing film, resulting in oil return. Therefore, during the printing process, the printing temperature should be properly controlled.

4. Avoid over-printing

Over-printing will cause too much ink to remain on the printing film, which is easy to be affected by moisture and oil return. Therefore, during the printing process, the amount of ink used should be controlled to avoid over-printing.

5. Clean the print head regularly

Regularly cleaning the print head can keep the print head in good condition and avoid excessive ink remaining on the printing film due to blockage of the print head.

6. Properly store the heat transfer film

Whether it is the raw material of the printing film or the finished heat transfer film that has been printed, it should be avoided in a humid environment (such as a basement or bathroom). The printing medium easily absorbs moisture, and the heat transfer film affected by moisture can cause ink scattering and other phenomena. Therefore, please be sure to wrap the film, seal it well and store it in a ventilated and dry place.

.jpg)