1. Material Problem

Since white ink heat transfer printing is performed on the surface of the fabric, if the material of the fabric is not suitable for heat transfer (such as materials that deform easily after heating), the fabric will shrink due to its material problems during the heat pressing process, which will cause the white ink heat transfer to deform easily.

2. Improper heat pressing temperature

When white ink heat transfer printing is performed, heat pressing temperatures that are too high or too low will cause warping problems.

If the temperature is too high, the fabric will deform excessively; if the temperature is too low, the heat transfer adhesive will not be sticky enough and cannot be firmly bonded.

3. Insufficient heat pressing time

When pressing white ink heat transfer print, if the heat pressing time is too short, the heat transfer adhesive will not melt and penetrate into the fabric fiber completely, and the heat transfer will not be firmly fixed, resulting in distortion.

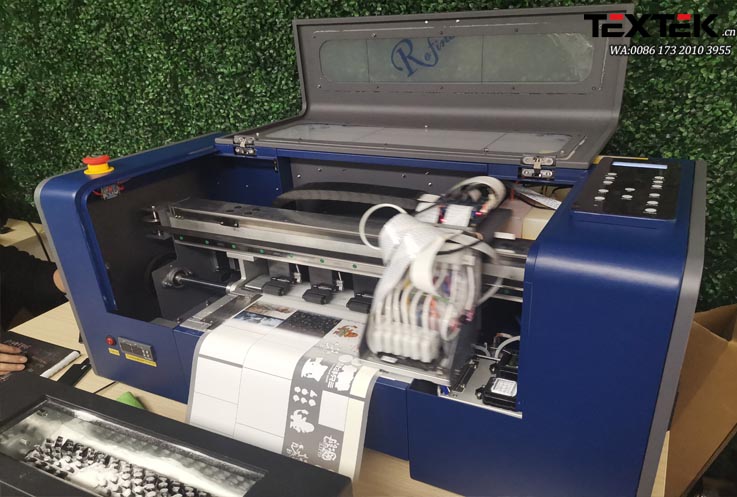

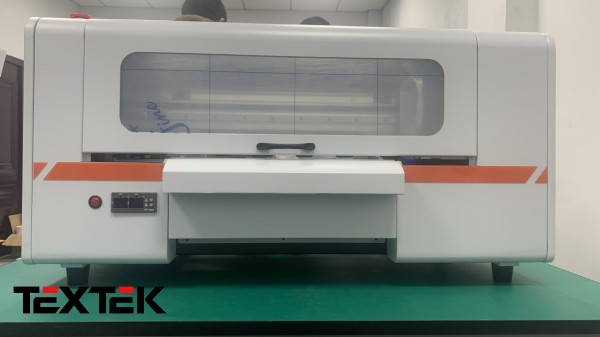

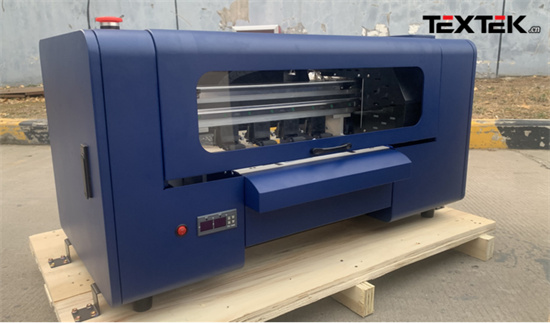

4. Equipment problem

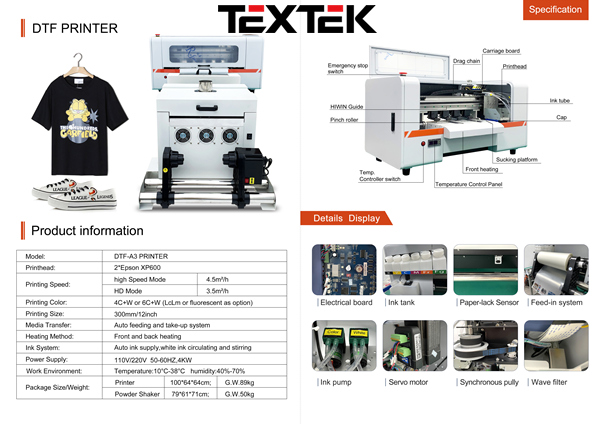

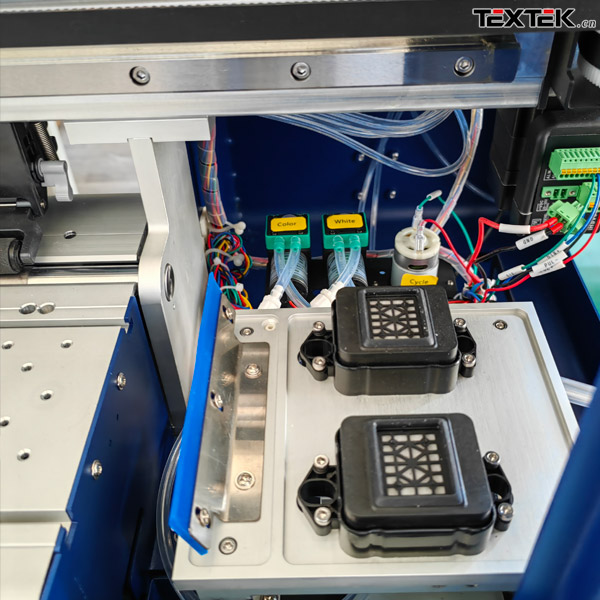

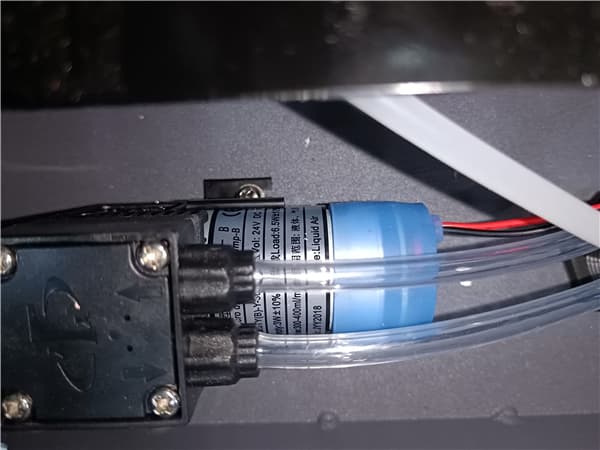

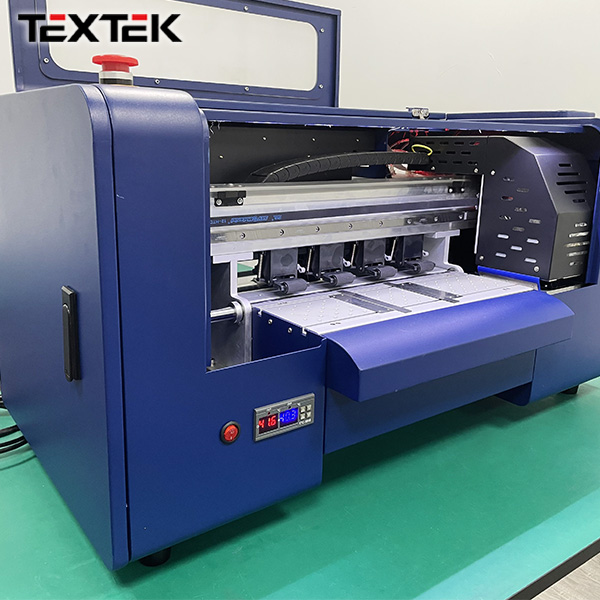

If the temperature control of the white ink heat transfer printer is inaccurate and the pressure is uneven, it is easy to cause uneven heat transfer and then warping. To avoid the problem of white ink heat transfer warping, you should choose a high-quality white ink heat transfer machine and use the correct operation method to perform printing work.

In addition, in actual operation, it is best to test a small piece of fabric first to determine the best heat transfer parameters. If you find the edge warping problem after pressing, you can repeat the pressing once.