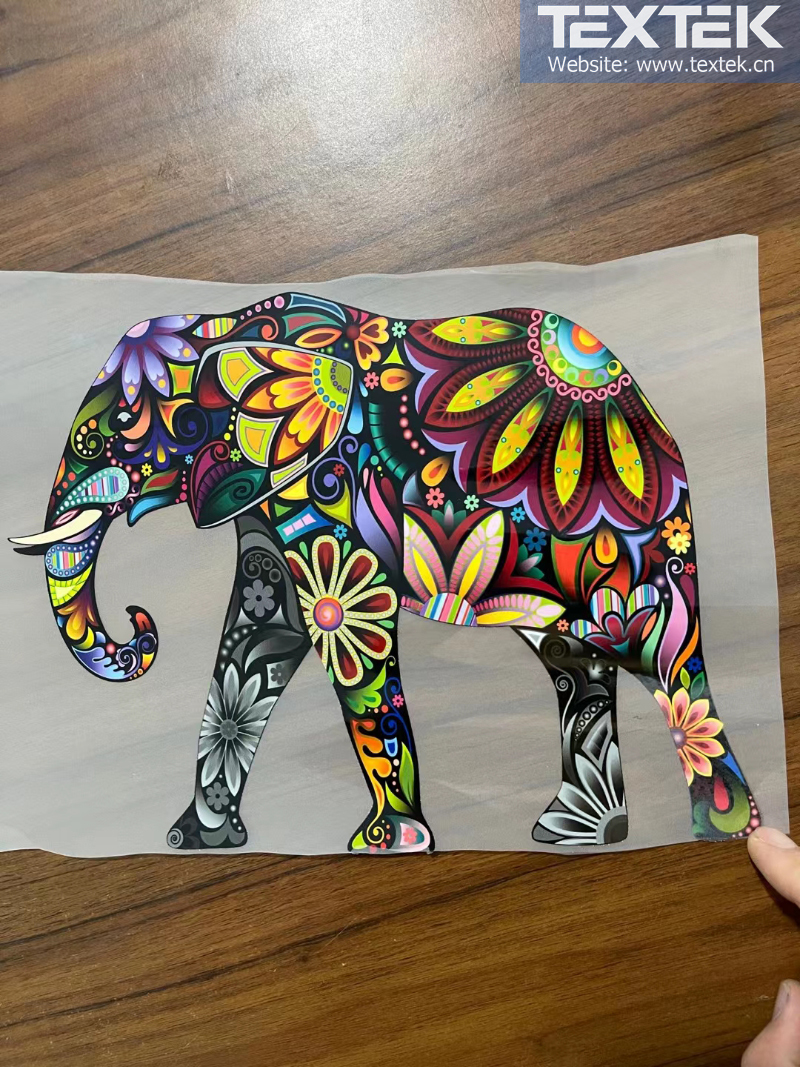

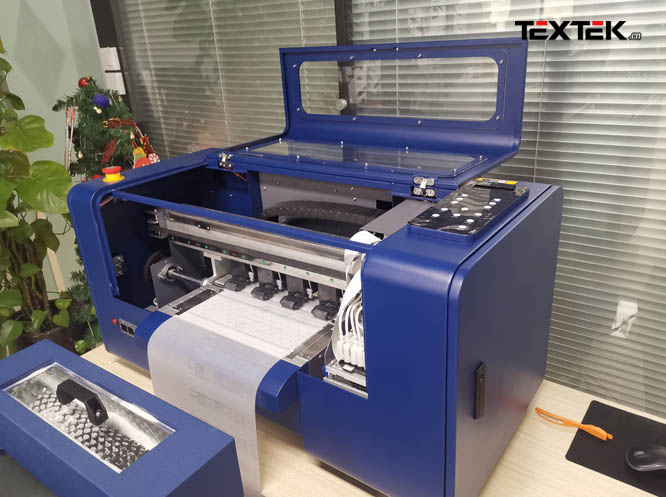

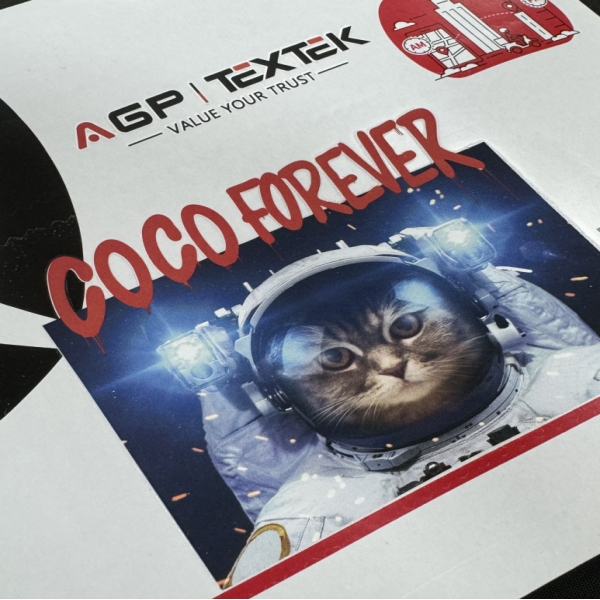

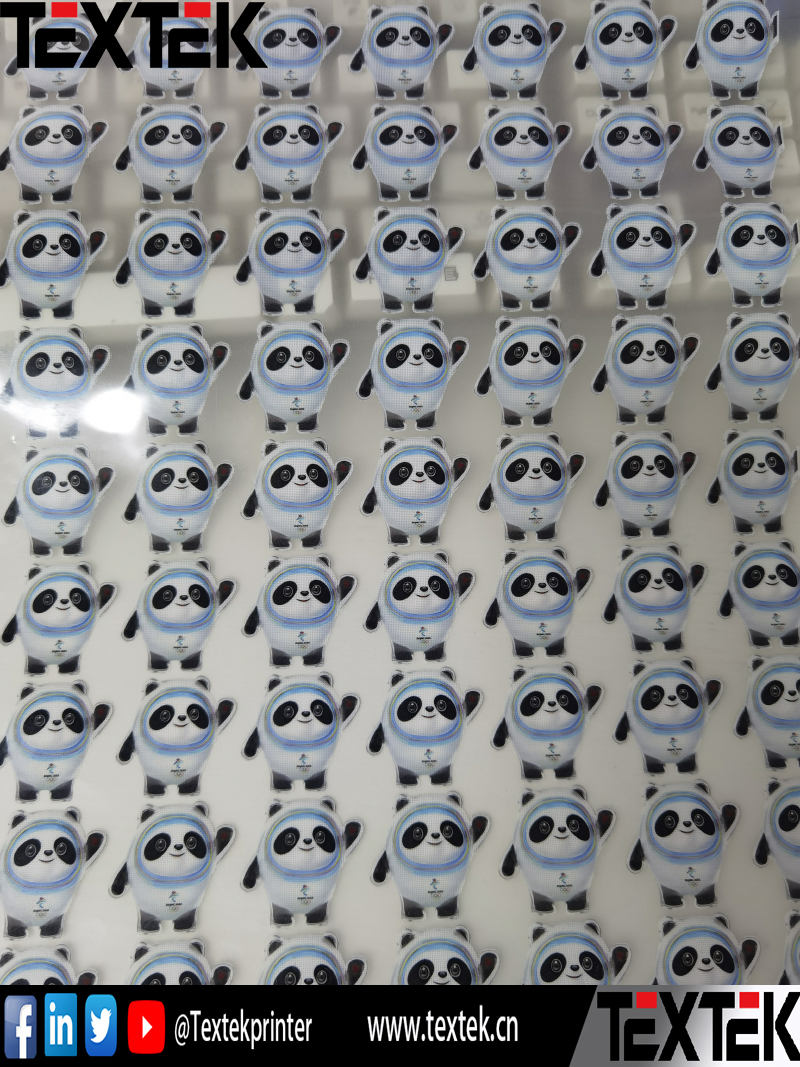

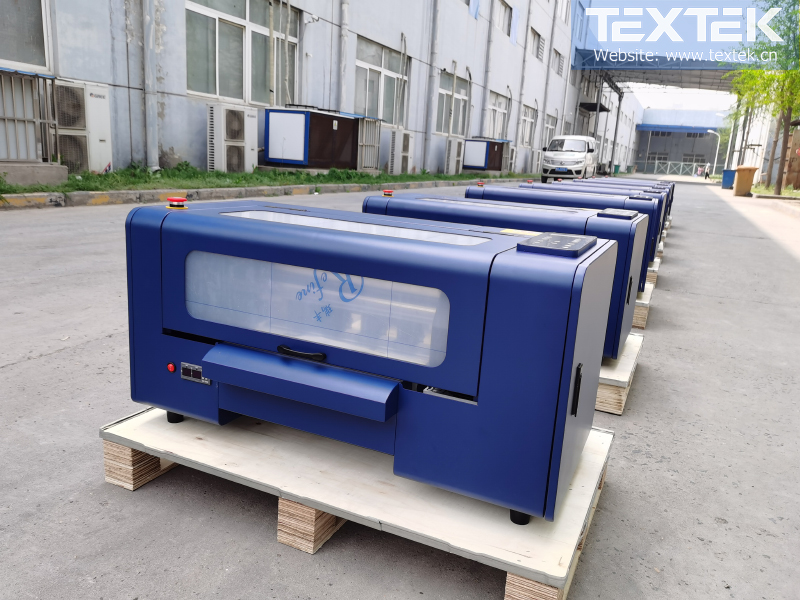

The pattern after the special printing film for white ink heat transfer has a texture like PU glue, which can be stretched and has strong elasticity without deformation. Textek white ink heat transfer PET printing film is suitable for most inks on the market, 100% ink volume can be used at will, no ink accumulation and no ink flow, it can easily achieve hot tearing, warm tearing and cold tearing. transfer film.

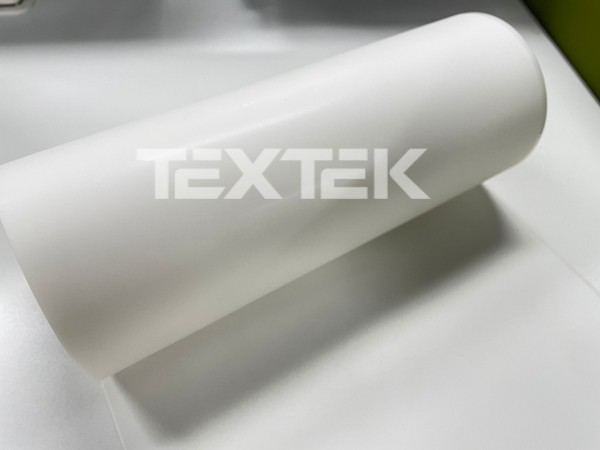

The ink-absorbing layer of Textek White Ink Heat Transfer Film is divided into five stages:

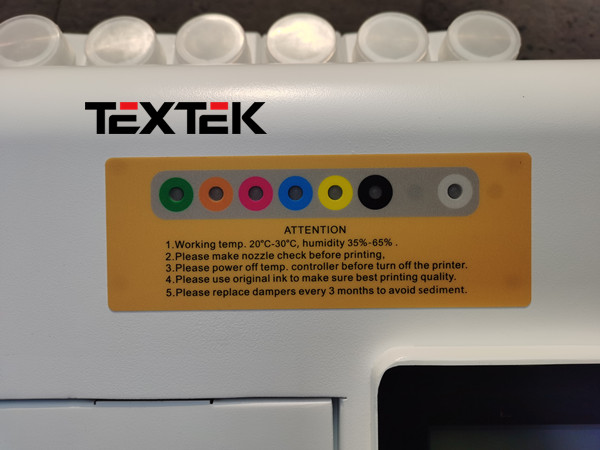

1. Anti-static and moisture-proof layer – the shaking powder is very clean, and there are no problems such as accumulation.

2. Water-based ink-absorbing layer – 0-100% ink volume, strong ink absorption, no ink flow and no ink accumulation.

3. Silicon wax release layer – can easily achieve hot tearing, warm tearing and cold tearing.

4. PET original film layer – can avoid problems such as arching, wrinkling, and yellowing.

5. Double-sided matte layer – can play the problem of non-slip dislocation, and the quality is stable.

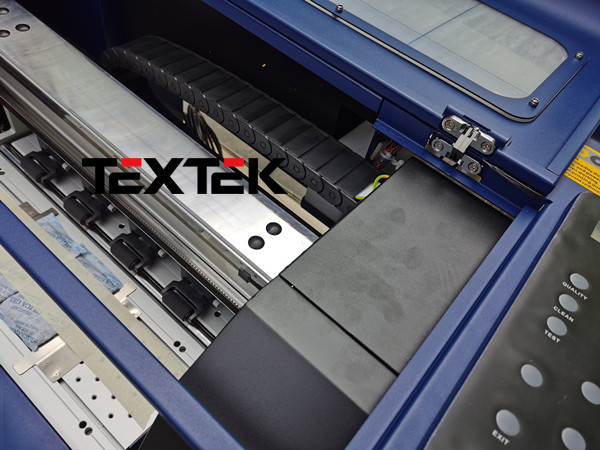

Note: The transfer pressing temperature is 140-160 degrees, between 6-10 seconds, according to different meshes of hot-melt powder, and the temperature zone of the fabric can be adjusted to the most suitable temperature zone, which can easily achieve second tearing.

.jpg)