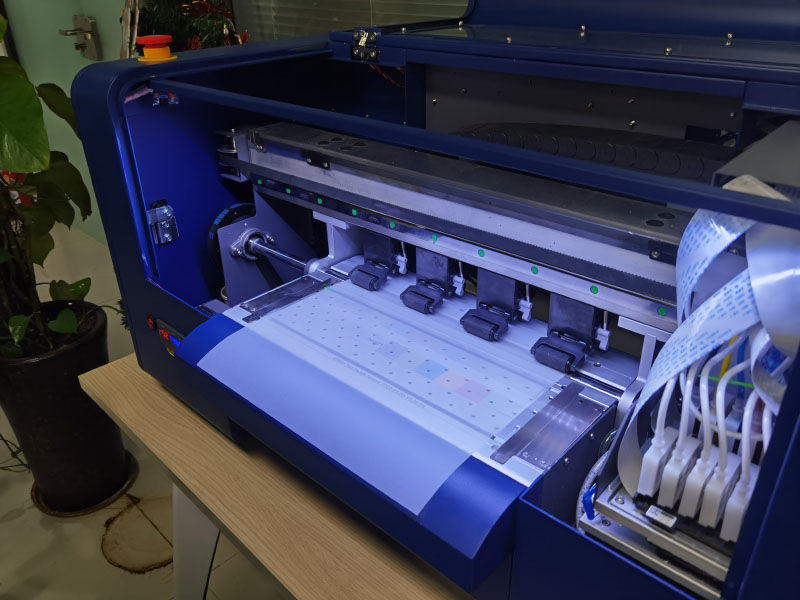

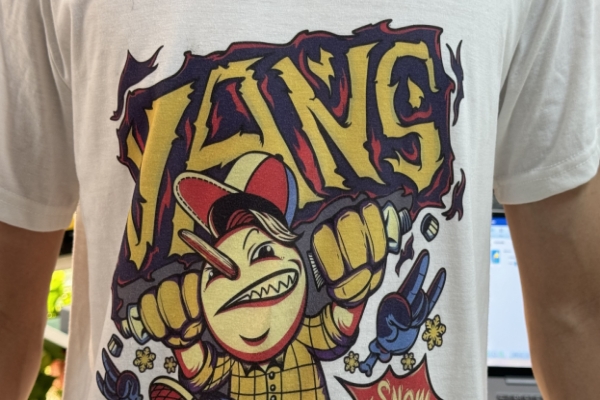

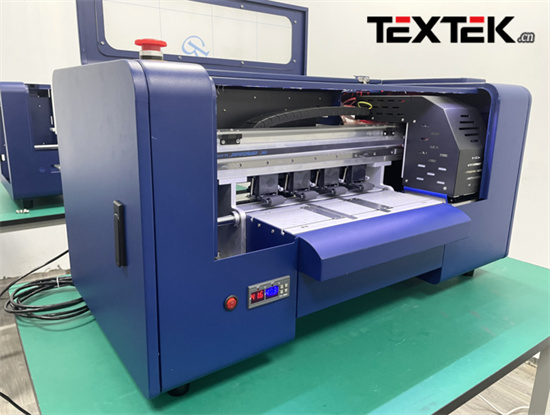

Direct to film printer is more suitable for thin fabrics in spring and summer

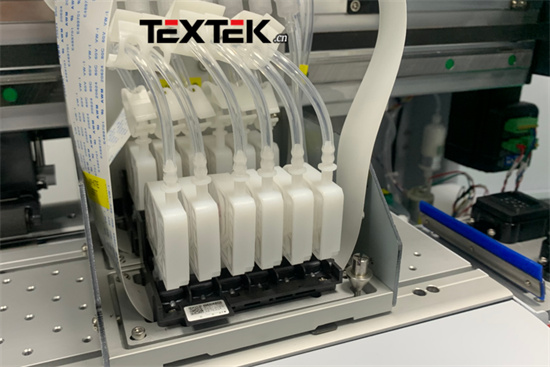

According to industry insiders, dtf printing products are more suitable for thin fabrics in spring and summer. The environmental protection of DTF printing technology benefits from the simplification of the production process, such as omitting or partially omitting steaming, washing, desizing and other processes, thus reducing water consumption and sewage discharge accordingly, and then To achieve the intention of protecting the environment, it can also save more labor costs.

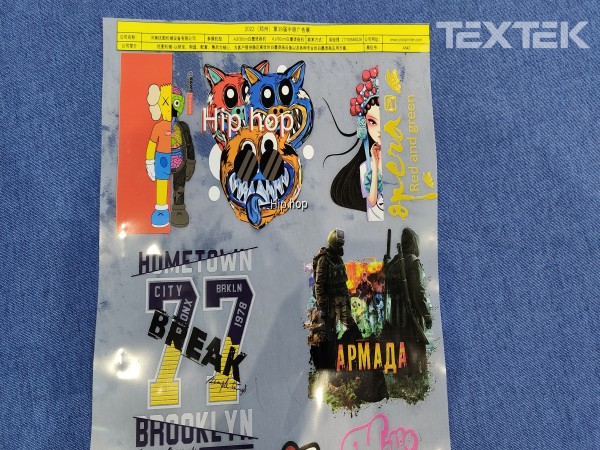

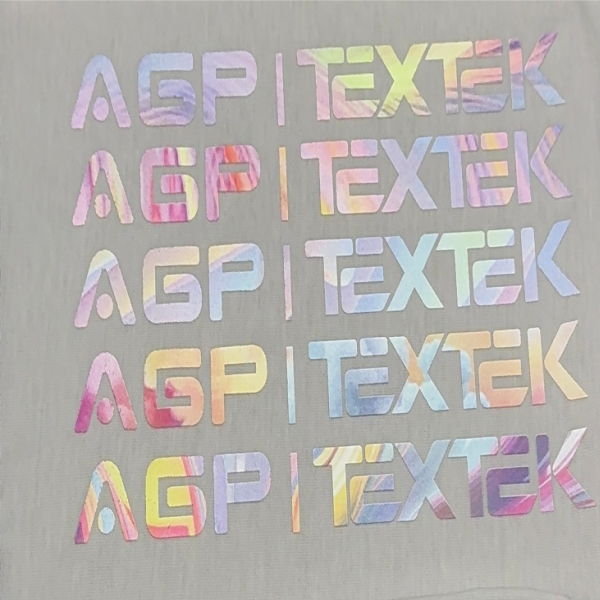

In addition to the advantages of being green and environmentally friendly, direct to film printers can also meet individual needs with digital printing technology. Today’s consumers are more inclined to seek personalized clothing, so more and more personalized customization orders are turning to small batch orders, which is just the right printing mode for dtf printing.

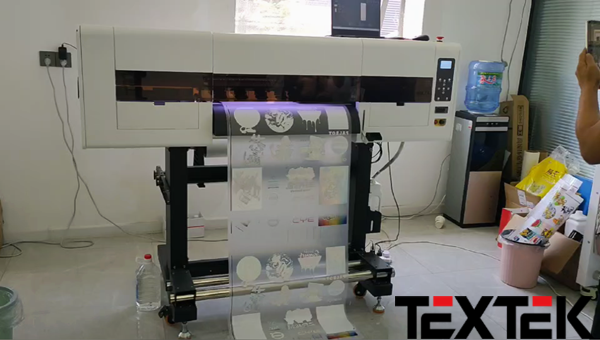

T-shirt printers are widely used, because the dtf printing process is to print the set pattern on the release film and then transfer it to the clothing, so dtf printing generally does not choose fabrics, whether it is pure cotton or polyester , silk, or leather can all be applied in the dtf process. The products involved are also relatively wide, such as T-shirts, pillows, shoes, jeans, school bags, etc. Therefore, the dtf process is not only suitable for spring and summer fabrics, but also for clothing in all seasons. All kinds of fabrics can use the dtf printing process.