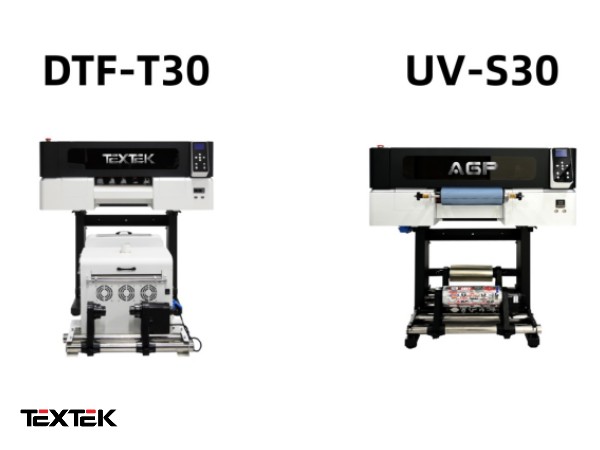

Speaking of direct to fabric printing machines, everyone knows that this is a very popular garment printing process. With its simple working principle, full color and green and environmentally friendly performance, it has become popular around the world and has become the most commonly used clothing printing process in printing factories. However, some people still have a partial understanding of the working principle of the dtf printing machine.

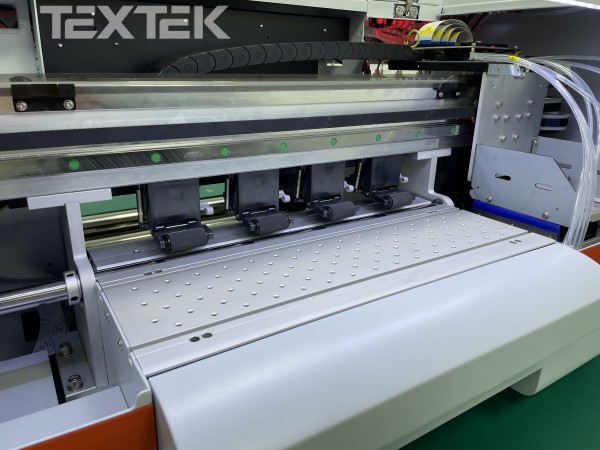

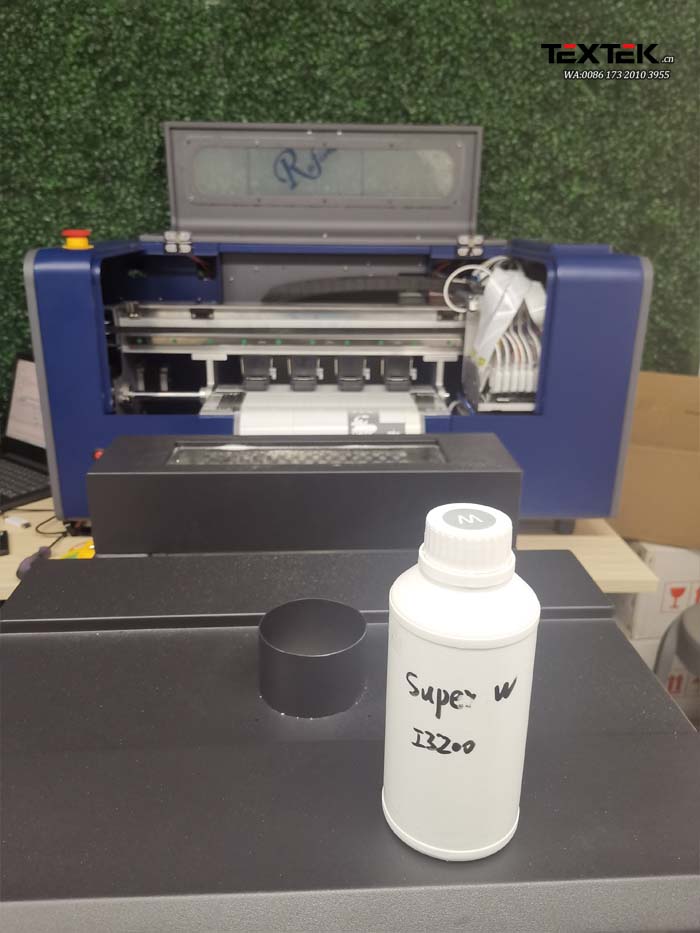

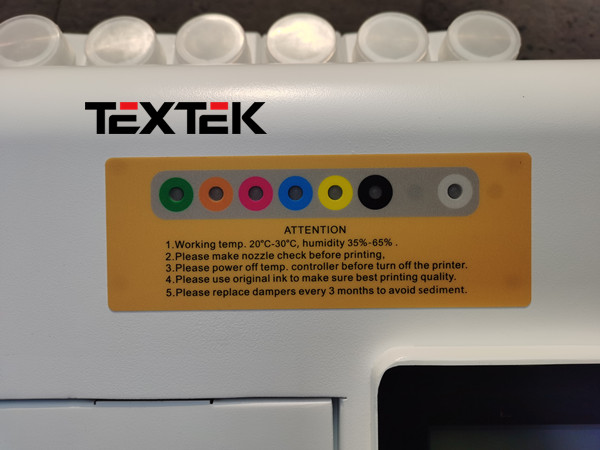

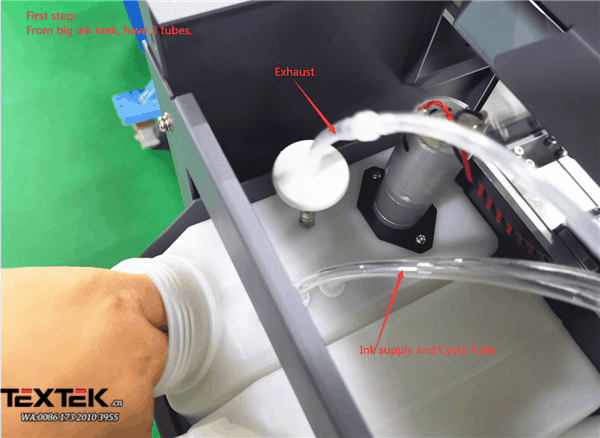

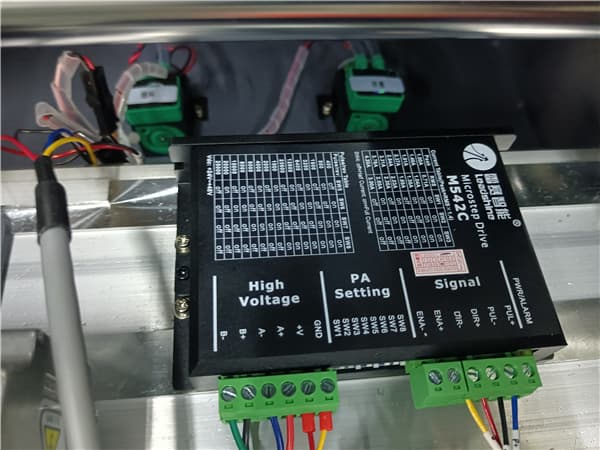

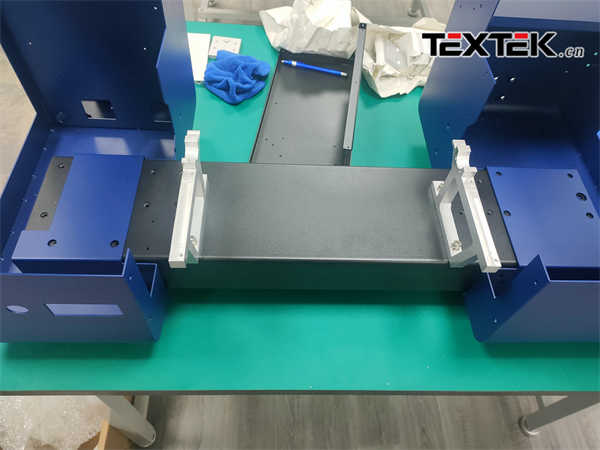

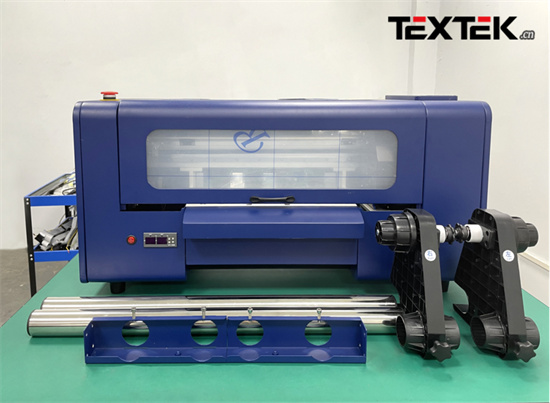

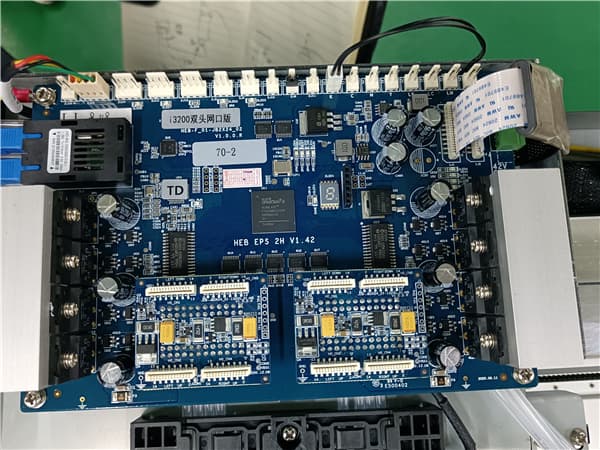

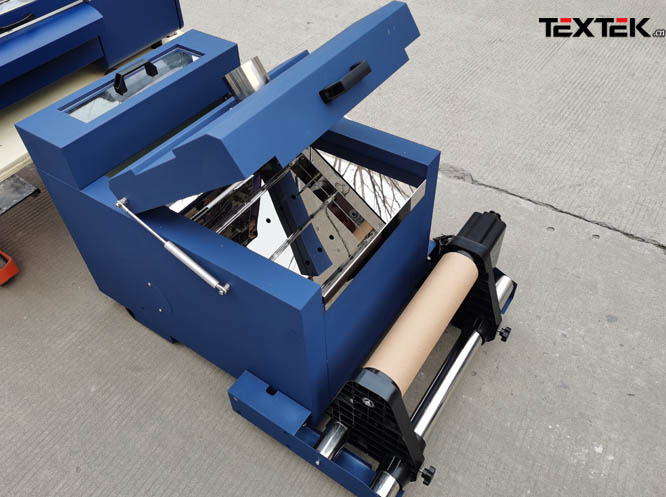

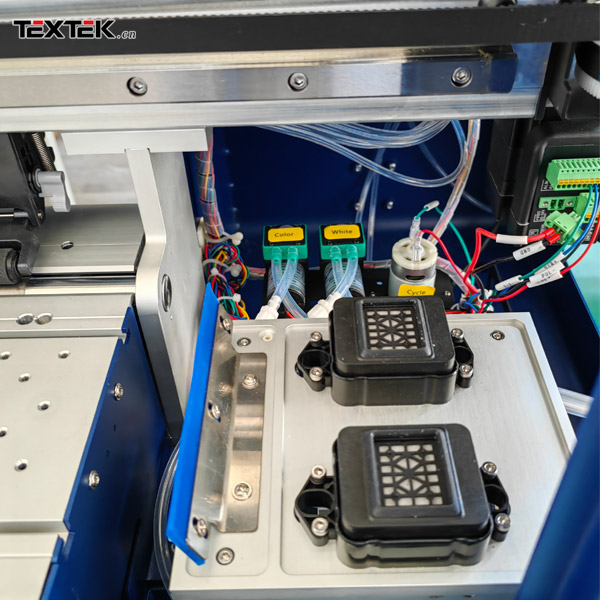

The structure of the dtf printing machine is composed of multiple components, including the main board, sensors, guide rails, printhead and display screens. The main board is the core of the entire system. It is responsible for receiving and processing information from sensors and controlling the actions of actuators. The guide rail cooperates with the printhead to move left and right to complete the printing task. The printhead is responsible for printing the received pattern information. The display screen is used to display information related to the dtf transfer printing machine, so that the user can intuitively understand the printing status of theTEXTEK dtf transfer printing machine.

The production principle of the dtf printing machine is that when the main board receives a printing task, the main control board will judge the user’s needs based on the received information, and then send the information to each accessory for execution. When other accessories receive instructions Finally, the actuators are controlled to make corresponding actions and cooperate with each other to complete the current printing task.

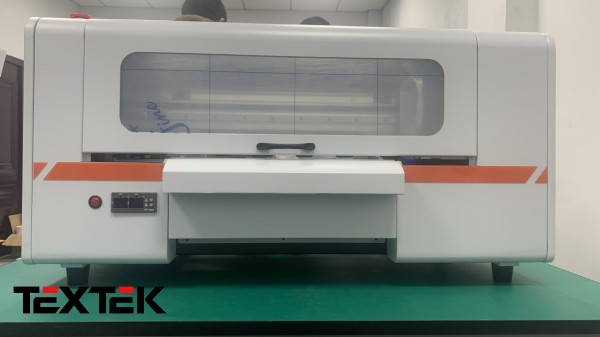

The dtf printing machine is an all-in-one garment printing machine. You only need to set the printing task and issue instructions, and the main board of the printing machine will execute the printing task. There is no need for manual operation at all. One person can watch multiple machines. The dtf transfer printing process has become popular in the printing industry because it requires no hollowing out, no waste discharge, and no need for plate making, and has become the most outstanding clothing printing process at the moment.