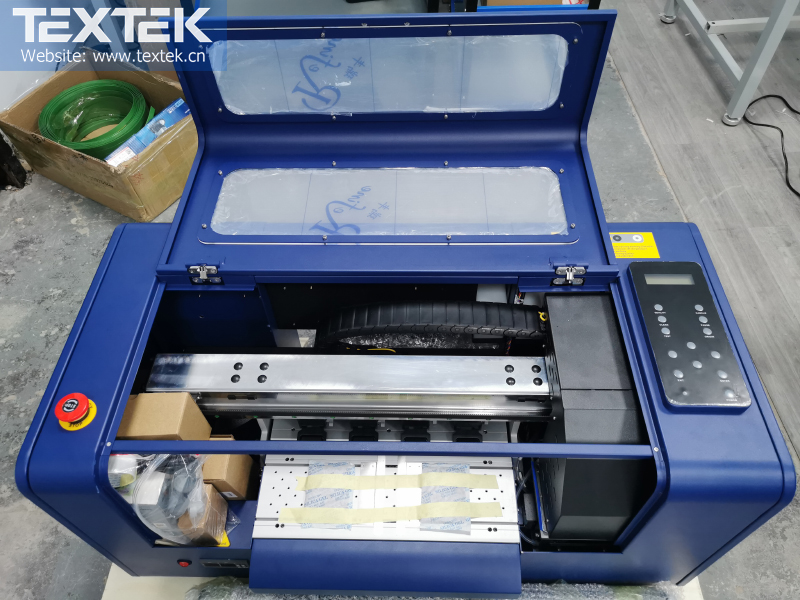

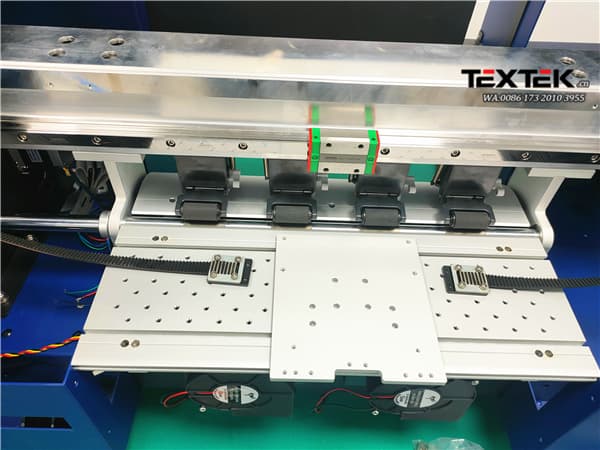

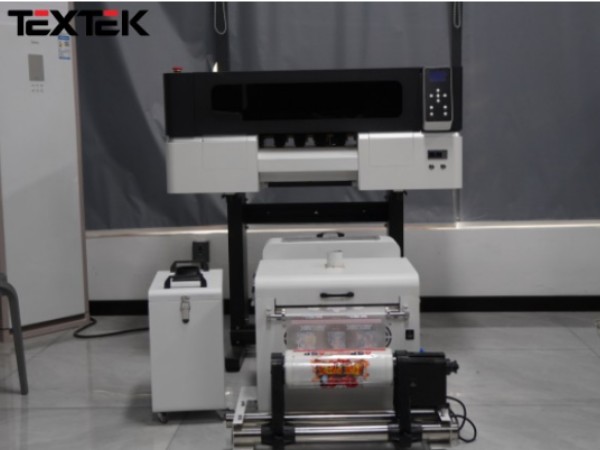

I think everyone knows that the nozzle of white ink heat press printer is an accessory that needs to be maintained very much, so how many people will pay attention to whether the guide rail needs maintenance? You may not pay much attention to this problem. In fact, the maintenance of the guide rail is also very important. If there are stains on the guide rail, it will greatly affect the printing progress and printing effect! So how should the guide rail be maintained? TEXTEK will give you a trick, all customers and friends of the white ink heat transfer printer processing factory can refer to it.

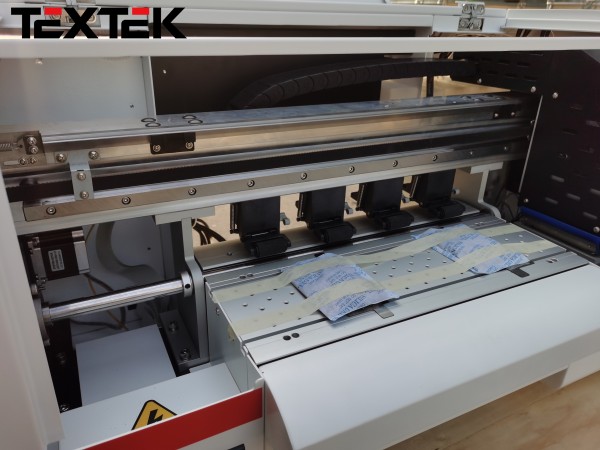

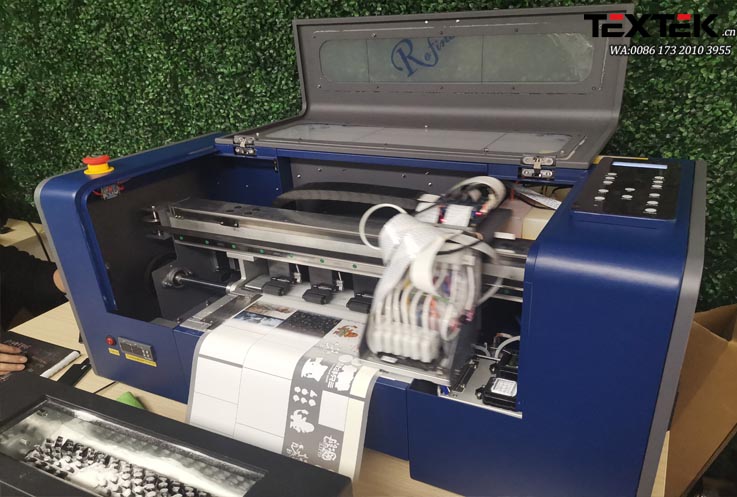

DTF Printer guide rail maintenance is a step-by-step process. After turning on the power of the printer every day, let the car run back and forth several times, and the dirt inside the guide rail slider will remain on the guide rail. Repeat several times, then wipe off the dirt with a non-woven cloth. If there are strong stains on the guide rail that cannot be wiped off with a non-woven cloth, you can use a small amount of alcohol or cleaning solution to wipe it clean.

Secondly, after the daily printing of the pet film printer is completed, the guide rail should be cleaned and maintained. Use a non-woven cloth dipped in alcohol to wipe off the dirt on the guide rail, and then wipe the guide rail with a non-woven cloth dipped in a little sewing machine oil. In order to prevent the stain from sticking for too long, it will be difficult to clean after hardening.

No matter what kind of machinery, it is very common to fail without maintenance, care and maintenance. Regular maintenance can save a lot of unnecessary failures, and less equipment failures is another way to save costs. Therefore, remember to maintain the guide rails of your white ink heat press printers on time every day to reduce failures and make them last longer!