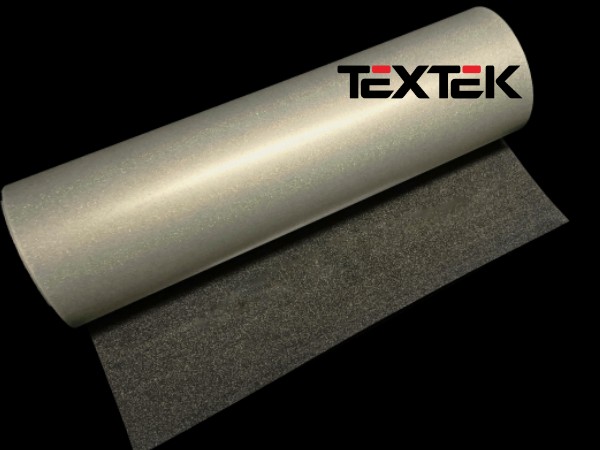

Why does PET film return to moisture and oil? The maintenance and preservation of the film is very important, especially in humid weather. We consider that the printing film is very easy to be affected. If the printing film is in a too humid environment for a long time, it will be easily damp and cause the printed pattern Oil back occurs. The quality of the printing film directly affects the working efficiency of the white ink heat transfer printer, so the storage method of the white ink heat transfer printer consumables in humid weather is particularly important.

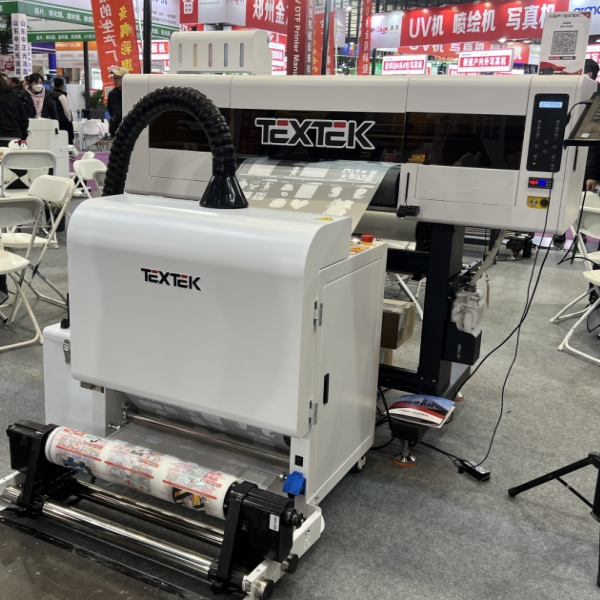

For the workplace of the dtf printer, if the weather is obviously getting colder or warmer, all doors and windows should be closed immediately, and the exhaust fan should not be turned on as much as possible, so as not to suck the humid air outside into the room. Generally, we recommend customers to install air conditioners in the workshop. Whenever the wet weather comes, you can turn on the air conditioner for dehumidification, or you can use the dehumidifier studio for dehumidification.

When storing PET film, more attention should be paid to moisture-proof, the film is easy to absorb moisture and be affected by humidity. Printed films affected by moisture are prone to ink scattering and oil return of printed patterns. Therefore, the printing film should be put back into the original packaging after each use, and try not to touch the ground and walls. If there is no packaging bag, you can wrap the bottom of the film, seal it and store it in a ventilated and dry place.

Printer film usage:

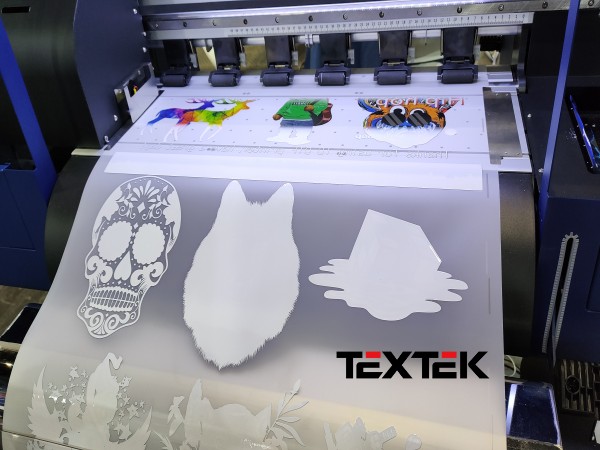

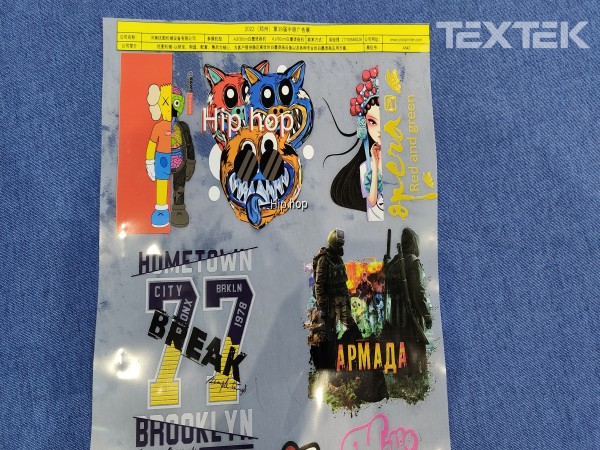

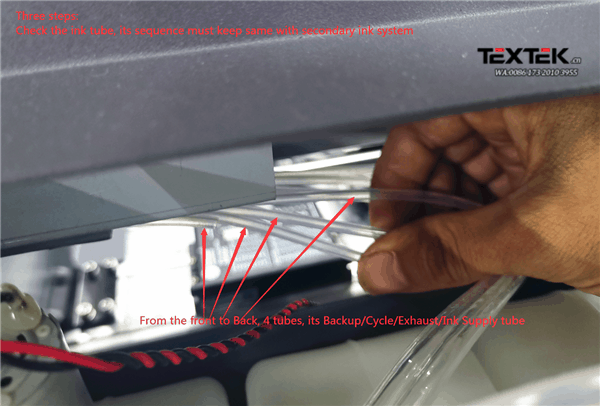

1. The ink-absorbing coating surface is the printing surface, handle with care, and pay attention to the anti-scratch ink-absorbing coating.

2. Bake for 40-90 seconds after printing (adjust the appropriate temperature according to the performance of the hot-melt powder).

3. Choose 60-80 mesh hot-melt powder to achieve instant tearing, 100-150 mesh hot-melt powder is recommended for warm tearing or cold tearing, and hot-melt powder above 150 mesh is recommended for cold tearing.