Do the following points well, and the failure of DTF Printer can be reduced by more than half

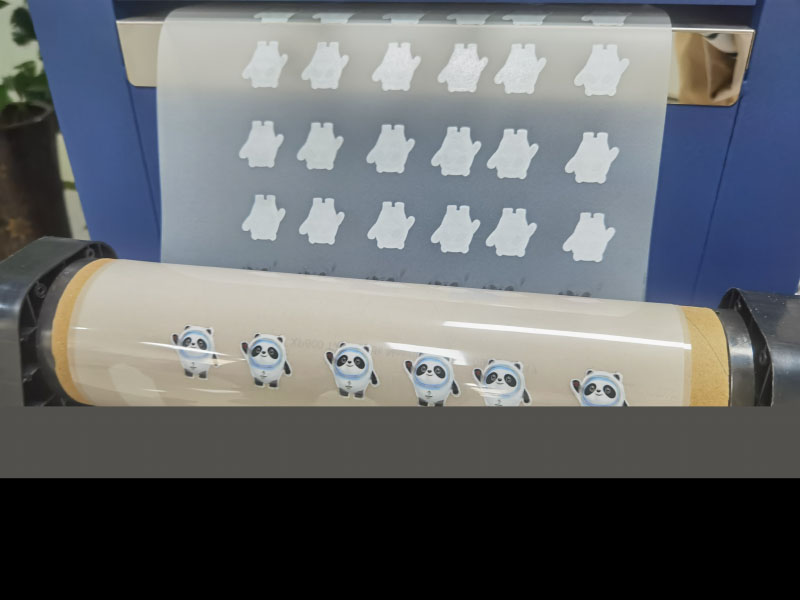

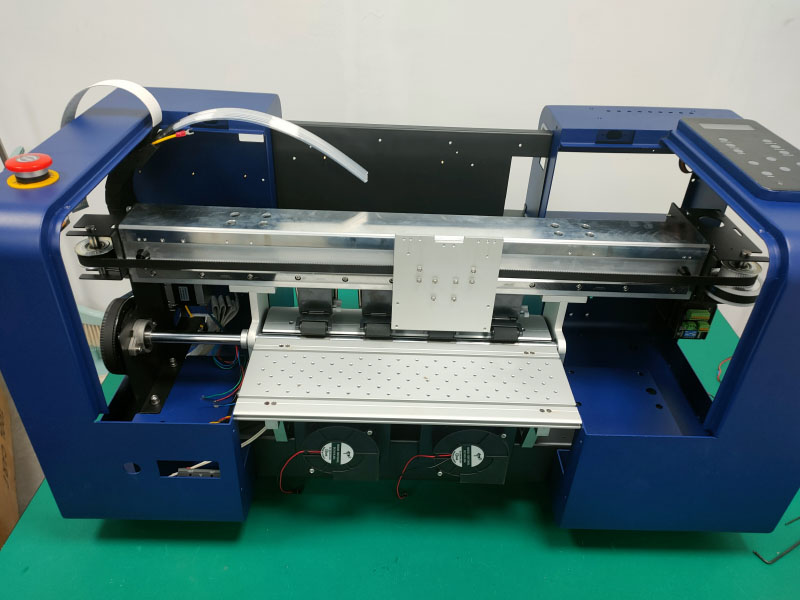

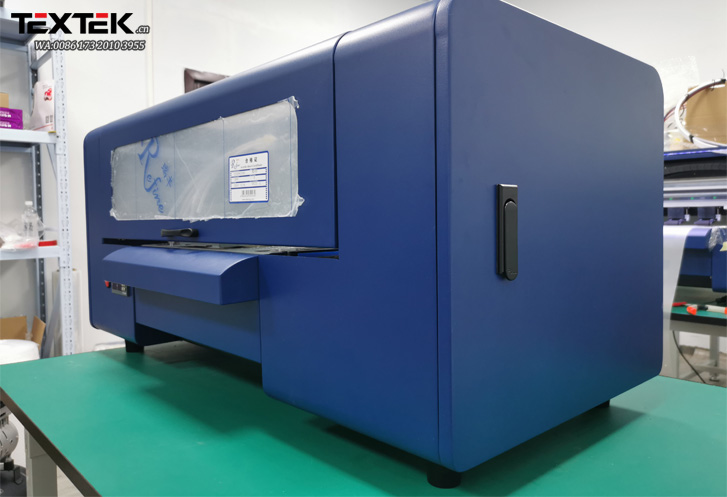

As a printing machine, DTF Printer requires daily maintenance. Effective maintenance strategies can prolong its service life and bring more economic benefits to manufacturers. Today TEXTEK has sorted out 7 maintenance tips for white ink heat press printing machines. As long as the following points are done well, the failure of the white ink heat press machine can be reduced by more than half.

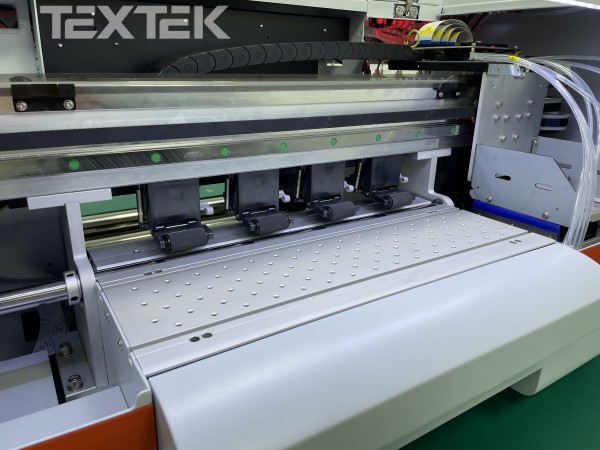

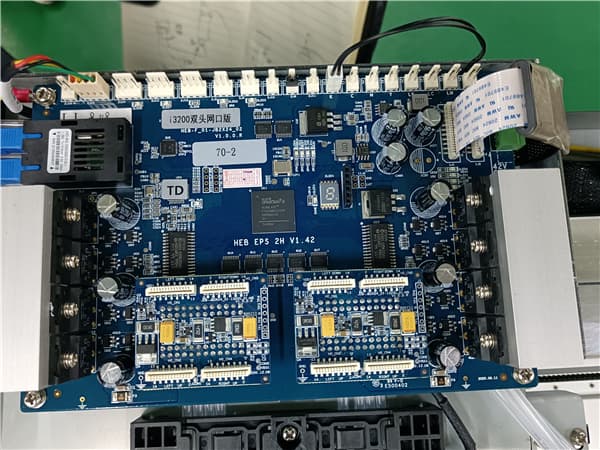

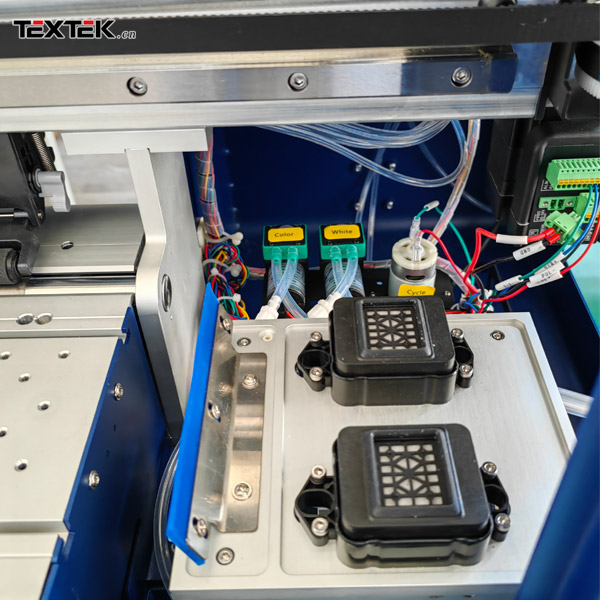

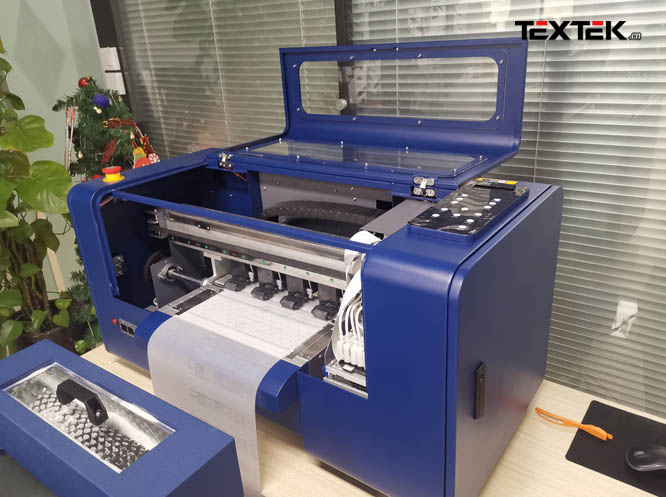

1. Clean the nozzles and ink cartridges regularly: If the ink is left standing for too long, it may cause precipitation. Therefore, the white ink heat transfer printing machine should clean the nozzles and ink regularly to avoid the phenomenon of partial oil circuit blockage. In this way, its printing quality can also be effectively guaranteed.

2. Regular oil replacement: Manufacturers who often use white ink heat transfer printing machines know that lubrication is an important part of printing machine maintenance, and keeping the oil passage of printing machine maintenance smooth is the core of maintenance elements. Therefore, it is necessary to regularly replace the machine oil and filter the oil circuit device, and do not allow impurities to flow into the pipeline.

3. Control room temperature and humidity: Generally speaking, within the relative humidity range of 40%-60%, the static electricity on the printing material is easier to be removed by transmission and will not affect the ink droplets on the nozzle of the direct printing machine, ensuring printing accuracy. It is recommended that windows be opened regularly in the office to ensure good ventilation.

4. Do not use ink with high viscosity: Although the weight of ink droplets is too large to reduce the electrostatic impact, but too high viscosity will have an adverse effect on the crystal of the nozzle of the white ink heat press machine.

5. Regularly check the flash spray and scraper: check the cleanliness of the flash spray and scraper at least once a week. If there are any debris such as hair, please use tweezers or facial tissue to remove the debris to keep the flash spray and scraper clean. tidy.

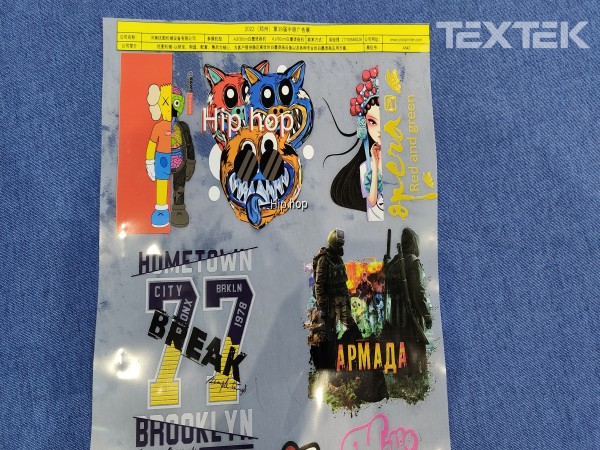

6. Regularly print test strips: If the nozzle of the printing machine is not used for a long time, it will cause the nozzle to be blocked. If possible, it is recommended to print the nozzle test strip every 3 days to check whether the nozzle is blocked. If it is blocked, perform cleaning operations to ensure that the nozzle is in the printing work at its best.

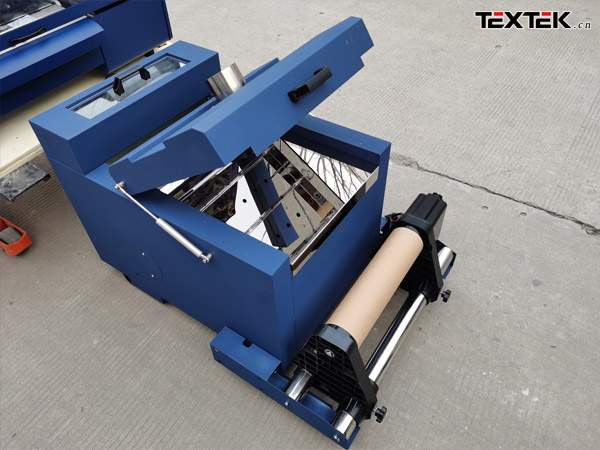

7. Do a good job of dust prevention: cover the printing machine with a dust cover after maintenance to prevent dust from contaminating the equipment. Cause damage to the printing device.