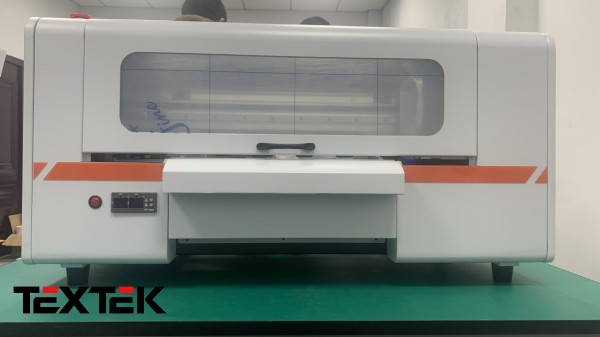

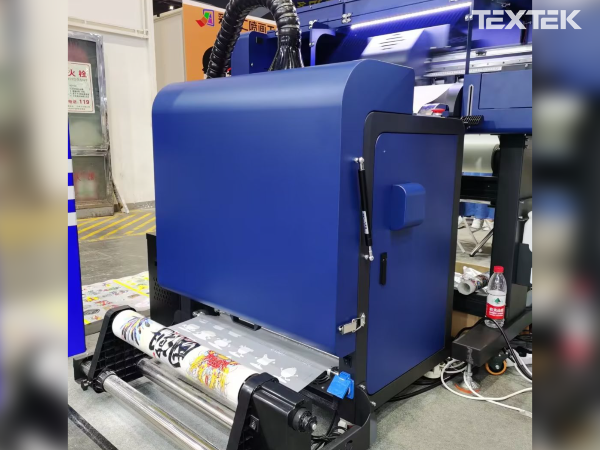

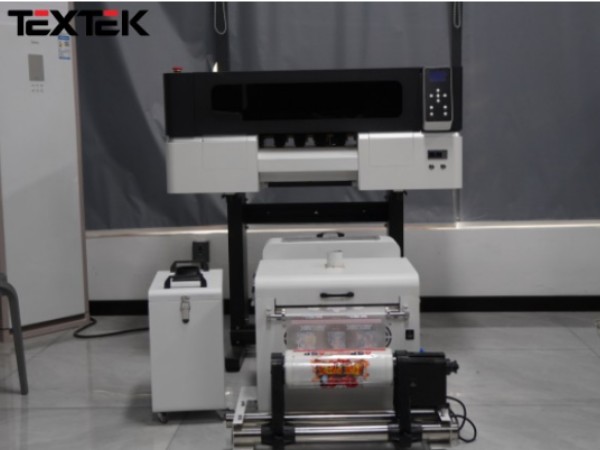

The T-shirt printer generally has a very long working time every day. In order to make it more effective for us and improve efficiency, we strongly recommend that the staff of the printing machine should perform periodic maintenance and maintenance on it every day. If the maintenance of the machine is usually neglected, the spare parts will be damaged first, which will shorten the life of the machine. Therefore, we provide some maintenance work and precautions to avoid the loss of time and human and financial resources due to improper maintenance. We hope that every machine can help you generate high economic efficiency.

The main maintenance instructions are as follows:

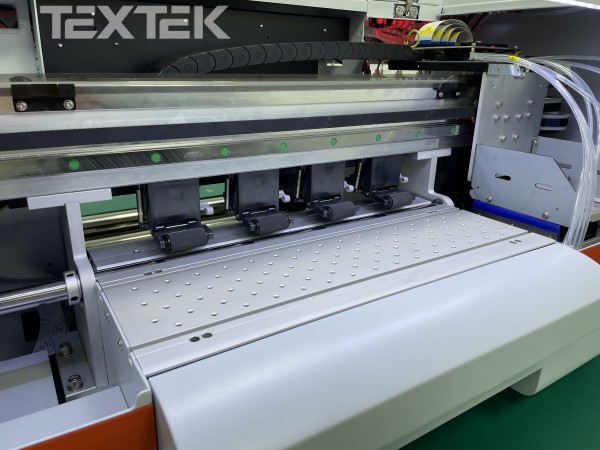

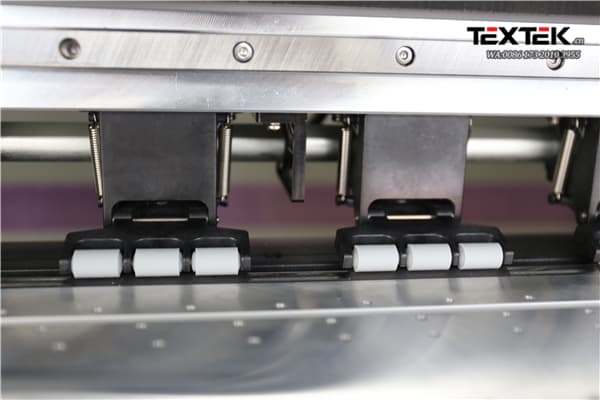

First: nozzle maintenance, as everyone in the industry knows, the nozzle likes to be blocked, but it will not be easy to block if the nozzle needs to print every day. Therefore, if the goods are not made on the same day, the nozzle should be printed with a test strip to check the status of the nozzle to avoid blockage. head. And do not wash more than three times!

Second: Check the ink remaining amount every day to avoid empty printing.

Fourth: The air source processor on the T-shirt printer needs to be turned off and drained twice a day; the aerosol oil should be adjusted to 4-5 drops per minute, and the air should be turned off when refueling.

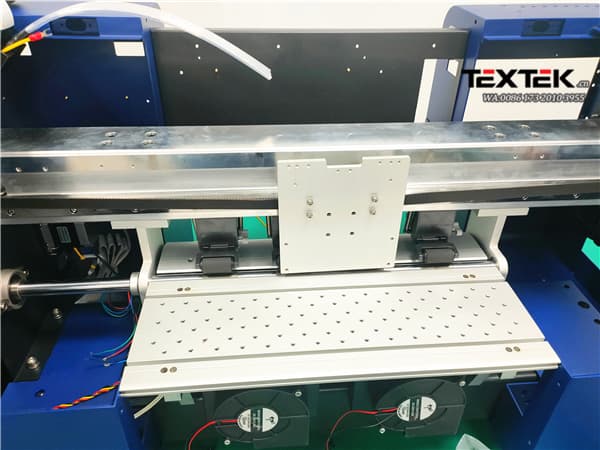

Fifth: Joint head, can drip butter (10-20g/time a week), oil (1-2 drops, 3 days/time).

Sixth: light shaft (machine movement part), butter twice a week.

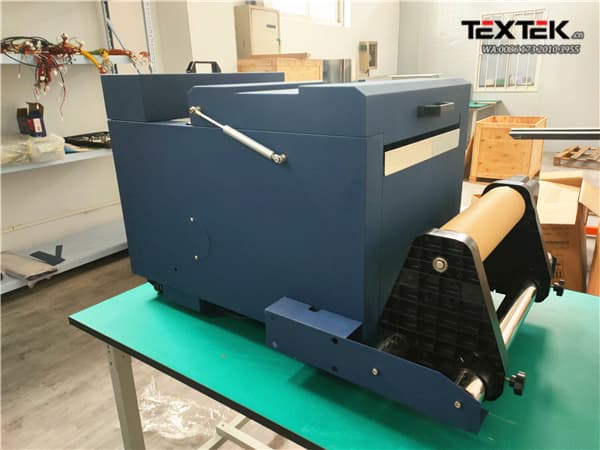

Seventh: emergency stop switch, the emergency stop switch on the printing machine should be used as little as possible to avoid the emergency stop affecting the life of the chain, drag chain and timing belt.