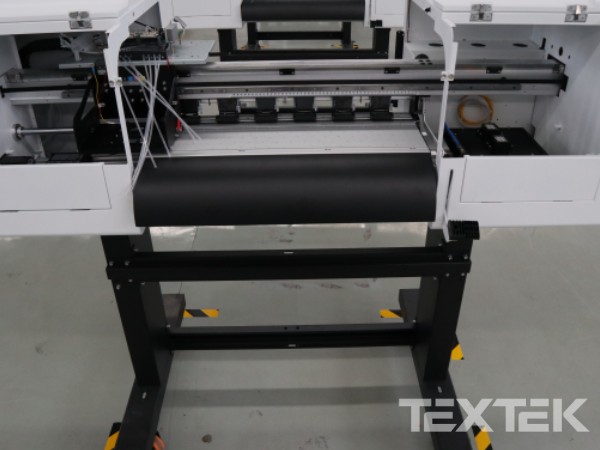

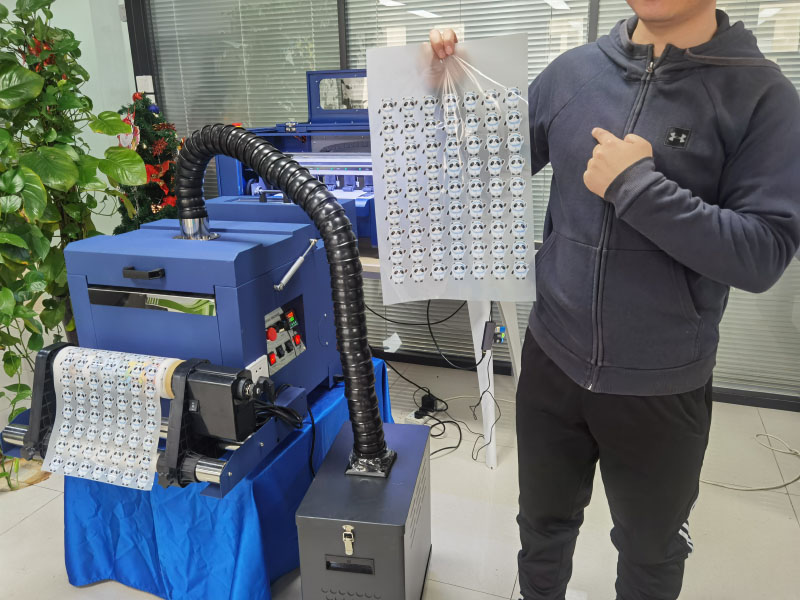

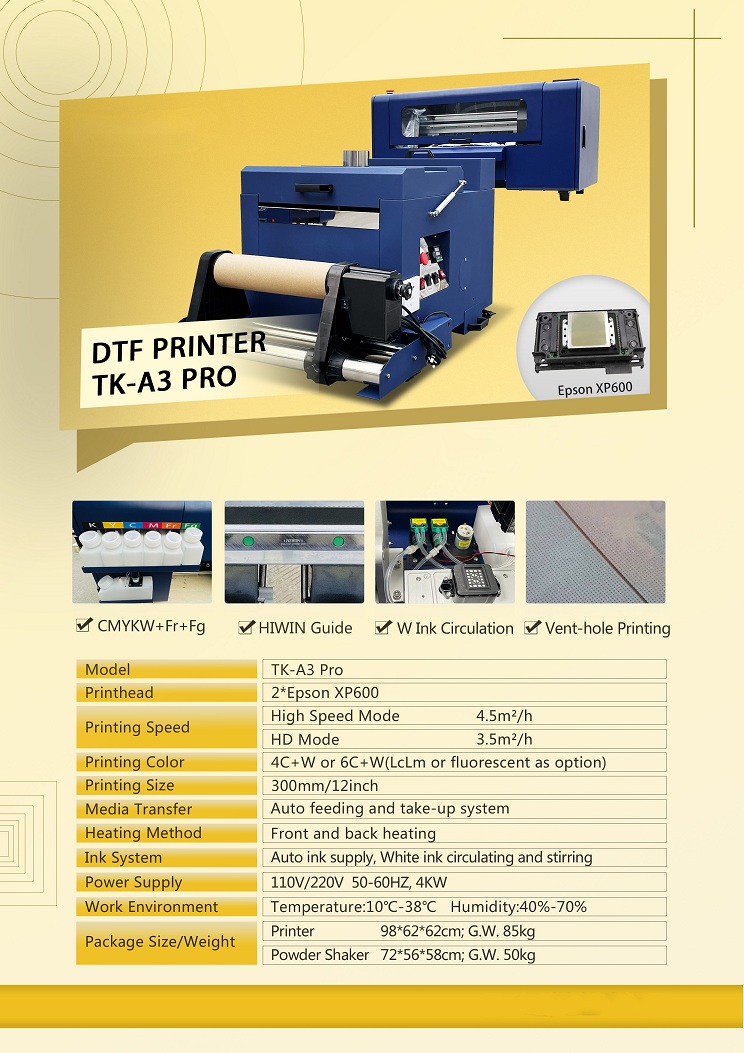

The print head clog is the single most important factor affecting the quality and yield of white ink heat transfer printer products.

Factors cause print head clogging

1. Ink quality

Poor quality ink is not available, and ink that is too thick or contains contaminants will clog the print head.

2. Ink Drying

If the ink in the print head dries prematurely, it will affect the normal inkjet of the print head.

3. Lack of maintenance

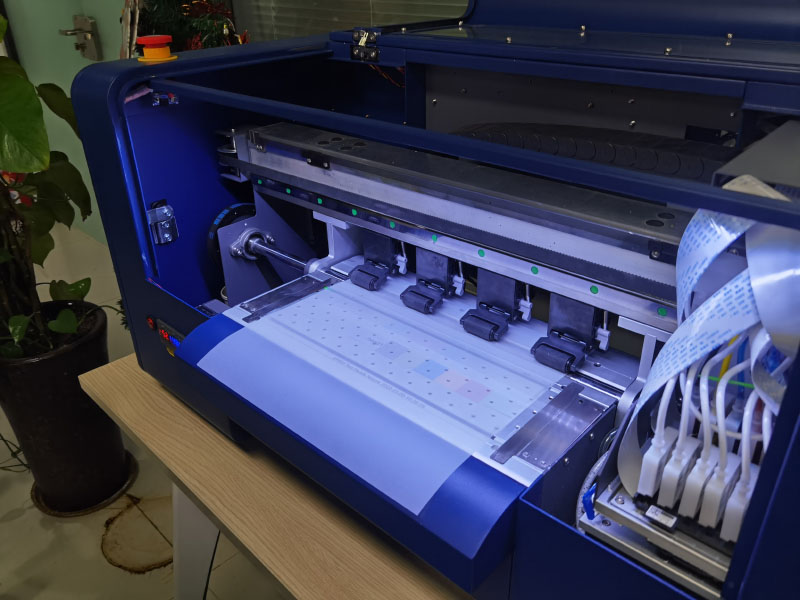

White ink thermal transfer printers are precision machines that require regular maintenance to keep the machine running in good condition. If the print head is not cleaned or the ink cartridge is not replaced in time, dirt and dried ink will accumulate in the print head, causing it to clog.

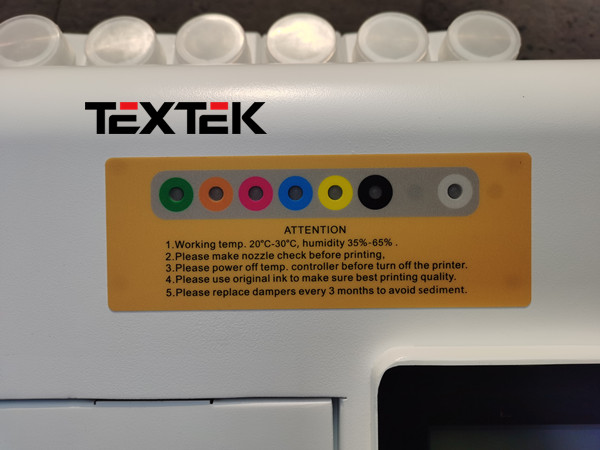

4. Environmental Factors

In an environment where the temperature is too high and the humidity is too low, the ink will dry too quickly, causing the print head to clog and the ink to be cut off. At the same time, the ink itself may evaporate, eventually increasing its viscosity and clogging the print head.

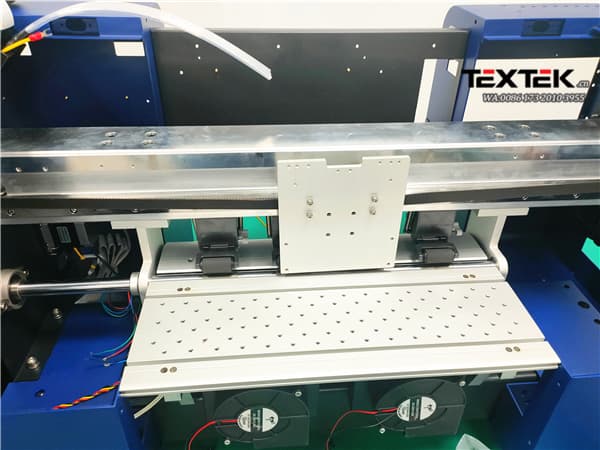

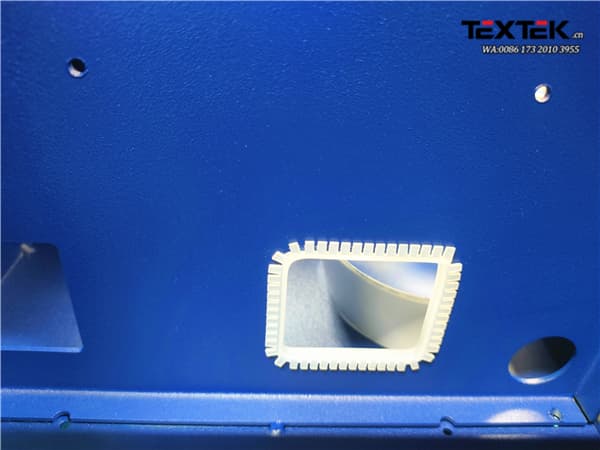

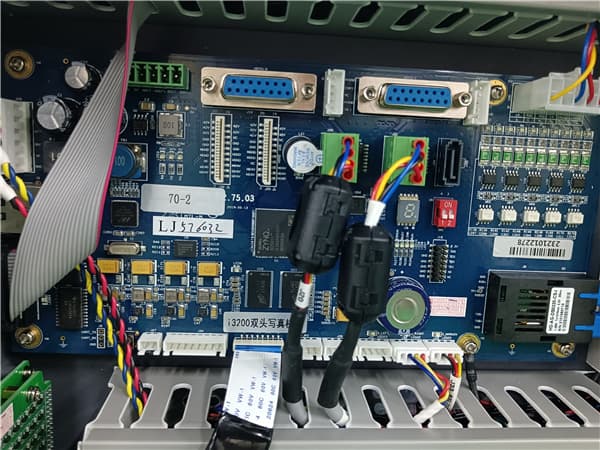

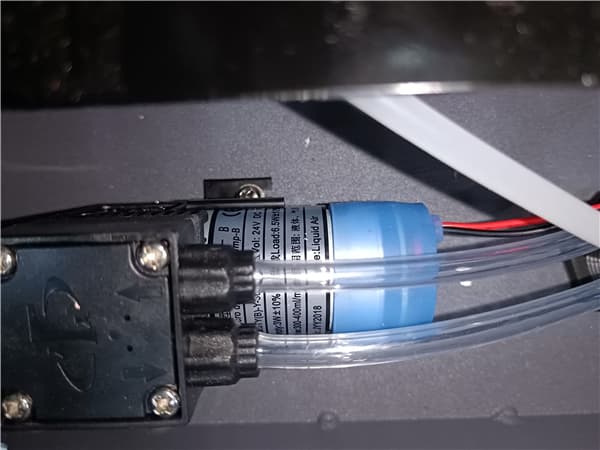

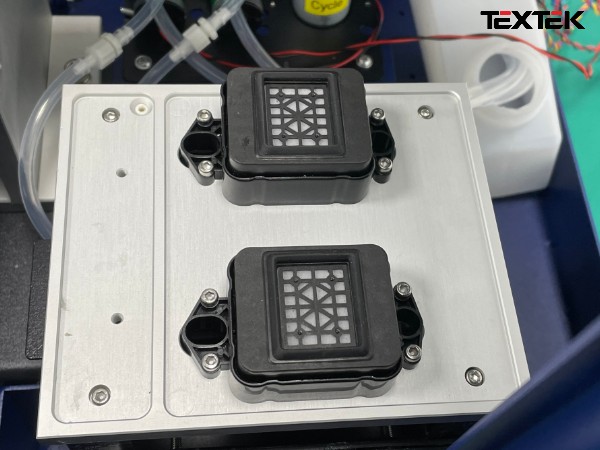

5. Ink System Problems

Ink system problems can also cause print head clogging. For example, a clogged filter or faulty pump will prevent ink from flowing through the print head.

How to prevent print head clogging?

1. Use high quality ink

Please use high quality ink that is compatible with your white ink heat press. (AGP recommends using original manufacturer’s ink, which guarantees quality and better compatibility with the equipment).

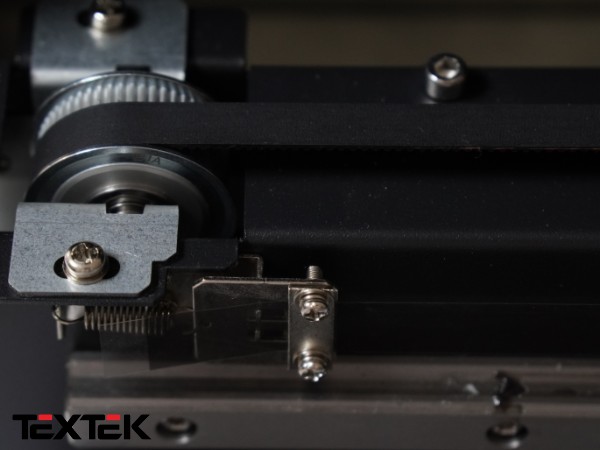

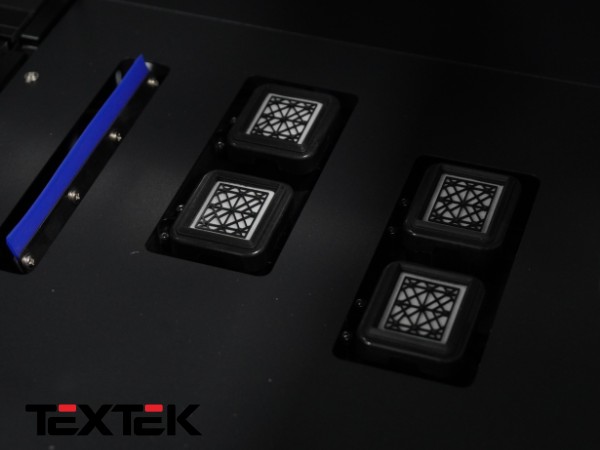

2. Clean the print head regularly

It is recommended to clean the print head once a week. When cleaning, use a special cleaning solution or distilled water for white ink thermal transfer printers and follow the machine maintenance instructions for cleaning.

3. Use a humidifier

A white ink heat press machine prints best when the working environment humidity is between 40% and 60%. A humidifier can be used to maintain ideal humidity levels in the room, which can effectively prevent the ink from drying out too quickly.

4. Regular Maintenance

Regularly cleaning the ink system, replacing ink cartridges when necessary, and promptly identifying and replacing damaged parts can greatly reduce the likelihood of nozzle clogging.