Before buying a DTF transfer printer, you need to consider the following 5 things:

1. Market and business needs

2. Compare common printer models and performance

3. Necessary supplies and software

4. Compare supplier prices and services

5. Other equipment you may need

Consider DTF market and business needs

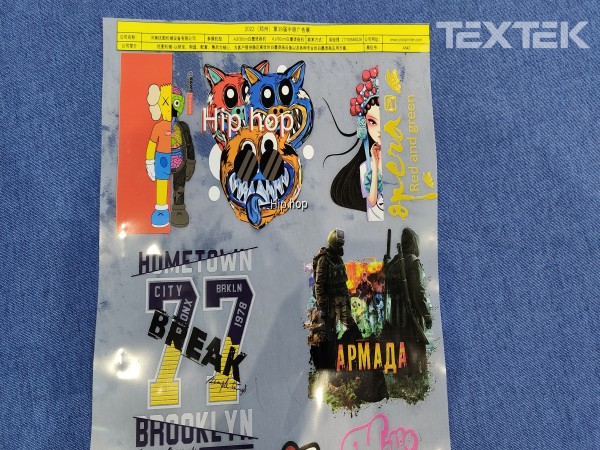

Analyze market needs and consider the types of prints and materials you want to produce.

Analyze the market in your area and understand the needs of the users. For example, if you want to start a custom apparel business, you need to consider the fabrics and the volume of business you can handle. Different materials will affect the quality and durability of prints. You can narrow down your choices by understanding the width, efficiency, and features of the printer.

Compare common printer models and performance

Compare popular printer models and features

Compare printer specifications, configurations, speeds, resolutions, and more.

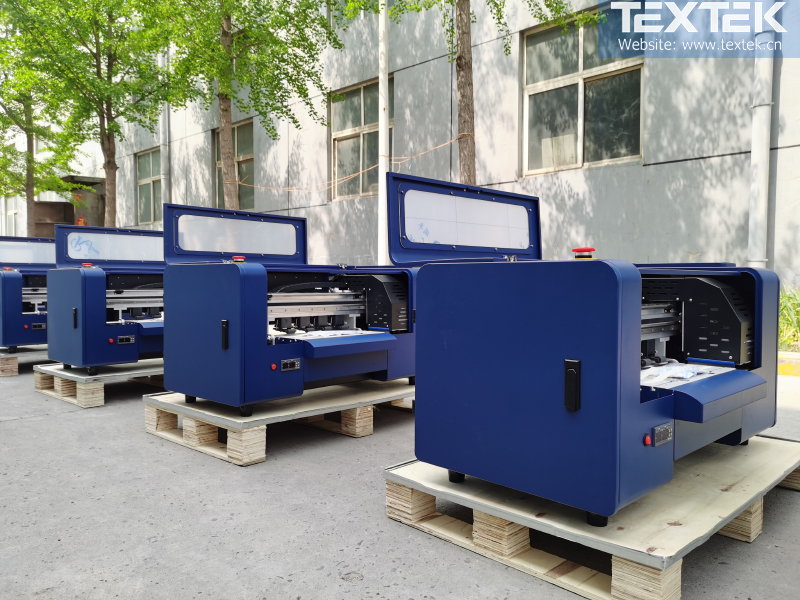

To find the right digital printer for your printing needs, you need to compare the features and performance of different printer models.

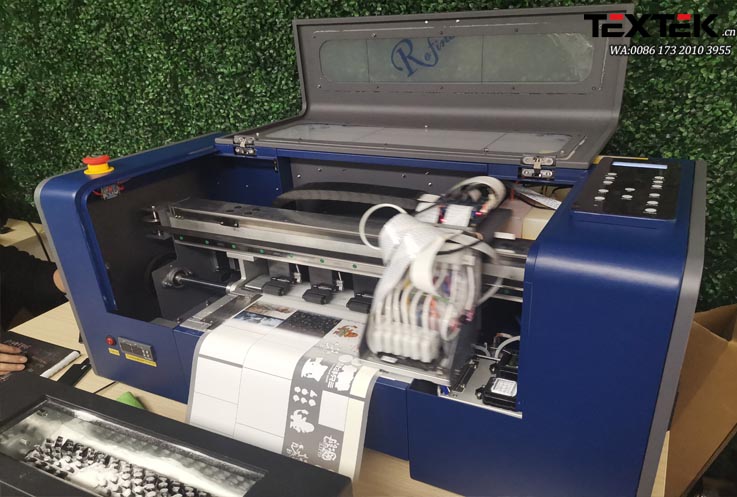

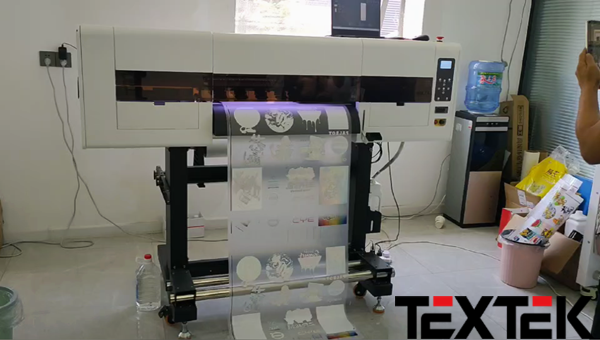

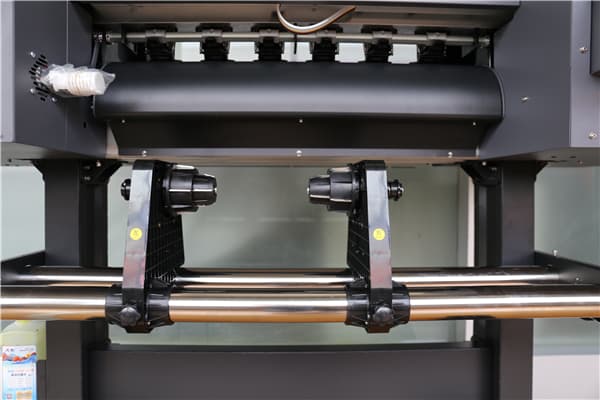

1. The first is width, where you can differentiate by print size.

For independent small businesses with relatively limited space and cost, you can choose a white ink heat transfer printer with a print width of 300mm. The small machine also has enough capacity to serve personalized businesses such as custom t-shirts, sweatshirts, hats, canvas bags, etc; Small and medium enterprises with a certain production scale can consider a 600mm wide white ink heat transfer printer for batch orders for quick response and timely delivery;

For professional garment printers for mass production, we recommend an industrial-grade white ink thermal transfer printer with a print width of 1200 mm, which helps to efficiently produce batch orders and ensures reliable quality.

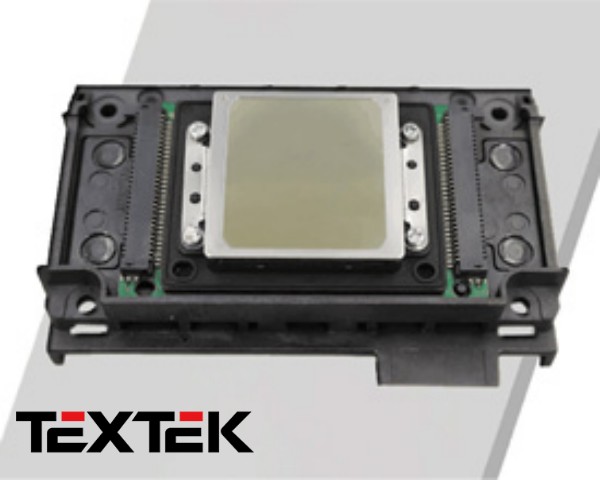

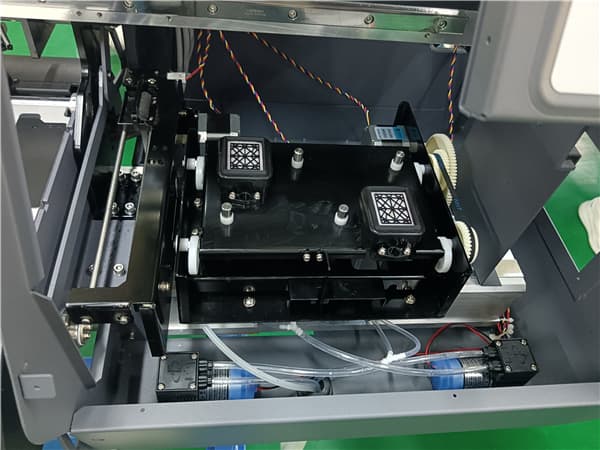

2. The second is performance. Understanding the configuration of some key components is key to considering printer performance.

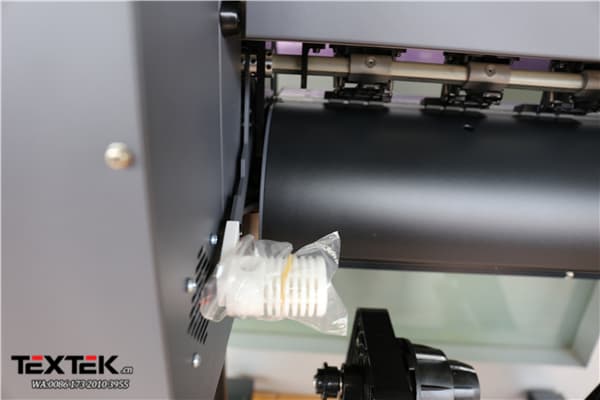

The printhead is one of the most important parts of a white ink thermal transfer printer. The type and number of print heads determine the print resolution and speed of the machine. At present, printers in the market generally use EPSON print heads because of their good performance and stability, which can meet the production needs of white ink thermal transfer printing with high resolution, durability, and fast printing.

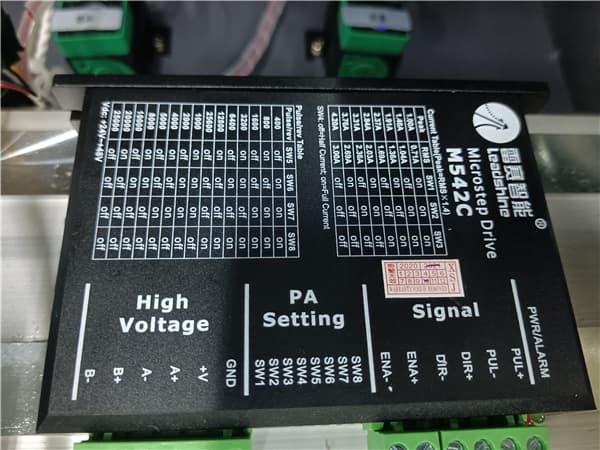

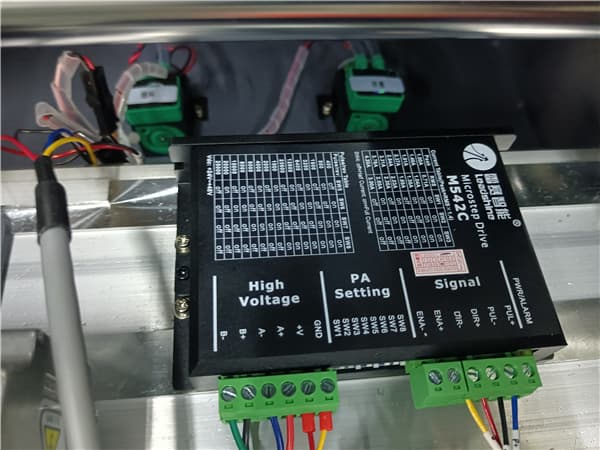

Another important component is the motherboard. The printer’s motherboard is responsible for coordinating the operation of hardware and software and receiving instructions from the computer to control the printer’s functions. At present, the Hoson motherboard is recommended, which has relatively stronger functions in data transmission, image processing, compatibility, etc.

3. The third is to consider the scalability and upgradeability of the printer to adapt to future business development and changing needs. Some printers may have upgrade options to add features or improve performance.

Required DTF Software and Supplies

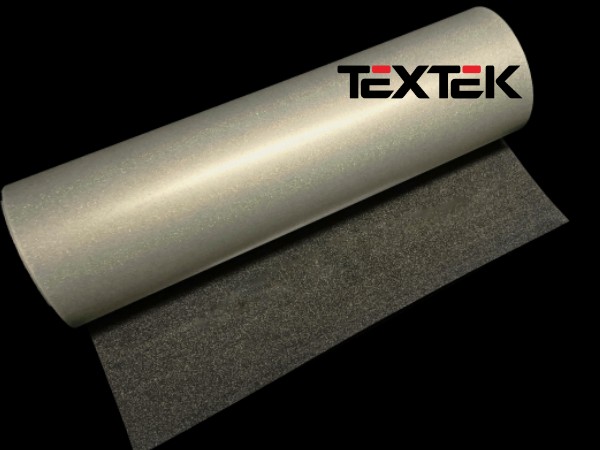

Also consider whether the RIP software, white ink heat transfer pet print film, DTF ink, and hot melt powder are compatible with the machine.

RIP software is responsible for converting digital image files into a format that the printer can recognize. It also manages the color information in the digital image, controls the printing process, and manages the ink supply system. Currently, white ink thermal transfer printers have specific software configuration requirements. The connected computer system should be Win7 and above, require a Gigabit network, and be able to adapt to Maintop 6.1 and above or photoprint 19 and RIP software. For specific installation and operation procedures of the software, you can ask the salesperson for the relevant instruction manual when you purchase the white ink thermal transfer printer.

To achieve high quality printing or efficient and high quality production, it is also crucial to choose high quality white ink heat transfer consumables. On the one hand, the use of high-quality consumables is a kind of protection for the printer, which is more conducive to the success of printing and ensures the stability of printing quality; on the other hand, it can also avoid material waste and control production costs.

Compare DTF supplier prices and services

Choose products and brands you can trust.

There is no set price range for white ink thermal transfer printers on the market, and different brands have different pricing strategies. However, it is important to remember that price comparisons should also take into account product quality and after-sales service. If the price of a particular device is significantly lower than other products of the same model on the market, the quality of the components or materials used in the product may be lower. In the long run, it may cost you more to repair it. Therefore, try to choose well-known brands and communicate fully with suppliers to understand whether they can provide perfect technical support and after-sales service.