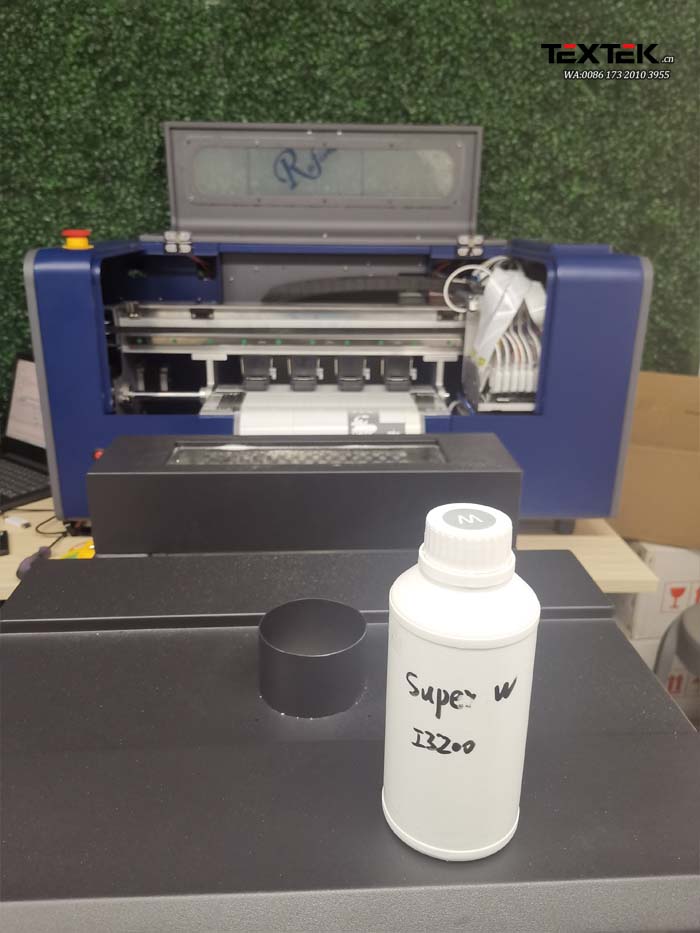

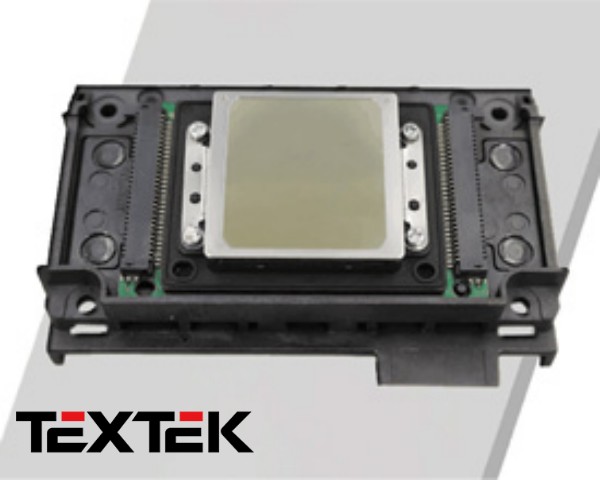

The fine printing pattern of white ink heat transfer printing machine can be easily controlled by controlling the ink droplet size of the inkjet printing head. Among them, the ink droplet of the Epson micro piezoelectric printing head is the smallest, and it can print images with an accuracy of 1440dpi, so the accuracy is also higher, the printed product will be finer and the effect will be better.

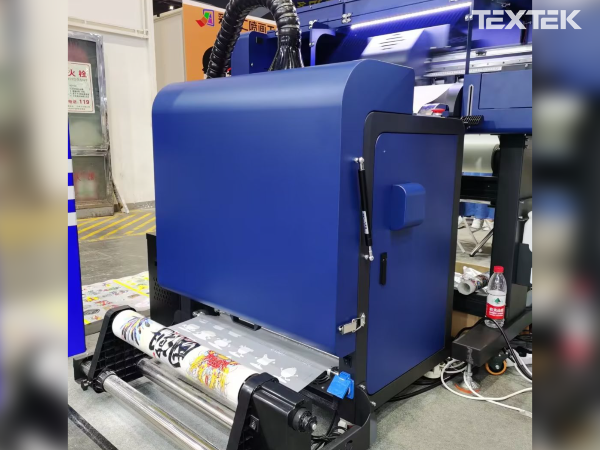

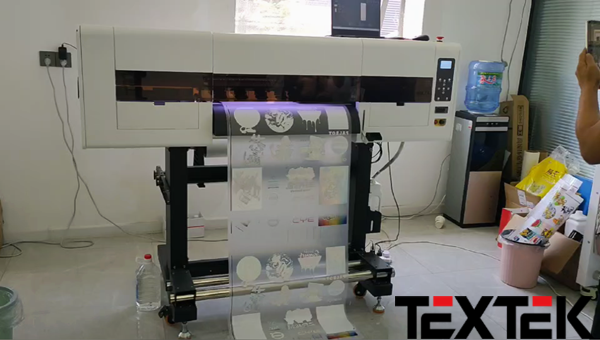

The white ink heat transfer printing machine will not produce too much waste during the production process, and there is very little waste ink during the entire inkjet printing process. The entire source of pollution is less than that of traditional printing machines, and has less impact on the environment and the health of those in contact. The white ink heat transfer printing process does not produce a large amount of waste water and waste gas like traditional printing. The entire printing process is very environmentally friendly and energy-saving, and will not cause any damage to the human body.

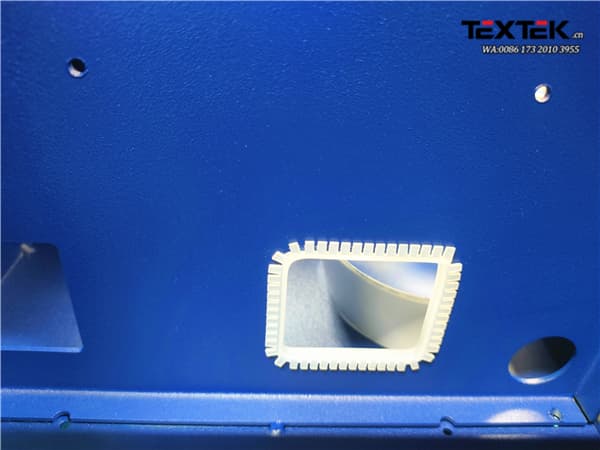

The environmental pollution caused by traditional screen printing is mainly reflected in the large amount of waste water and waste ink generated during the production process. In the printing production process, more or less bad solvents, even plasticizers, and heat It is possible to add non-environmentally friendly plasticizers to the lump ink, such as printing water, decontamination oil, white electric oil, etc. Printing workers will inevitably come into contact with chemical solvents, glues, toxic cross-linking agents, chemical dust, etc. in actual work, which will affect the health of workers.