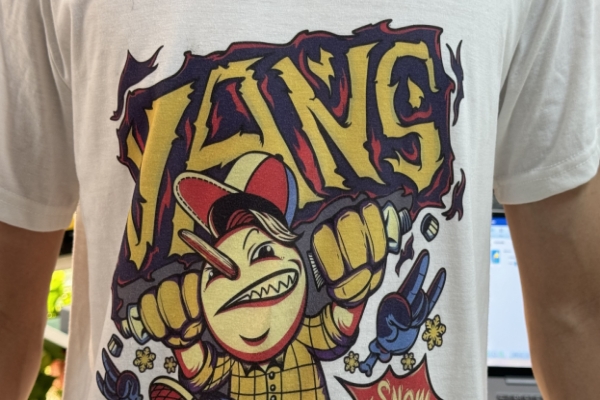

There are many kinds of clothing printing processes, the common ones are screen printing, offset heat transfer, white ink heat transfer, white ink direct injection and other processes. Among them, screen printing is only suitable for large-scale orders. The screen-printing technology is relatively complex, mainly including design, film production, printing, printing, and drying. The price will be cheaper when the goods are available.

Compared with the heat transfer process, the offset heat transfer process is more complicated. The time and consumables required will be higher than the heat transfer process and the direct injection process, and the labor demand will also increase. The white ink direct injection process has great restrictions on fabrics. It can only print pure cotton or fabrics with high cotton content, and the scope of use is small. However, the advantage of direct injection is that the printed pattern is more breathable and not stuffy.

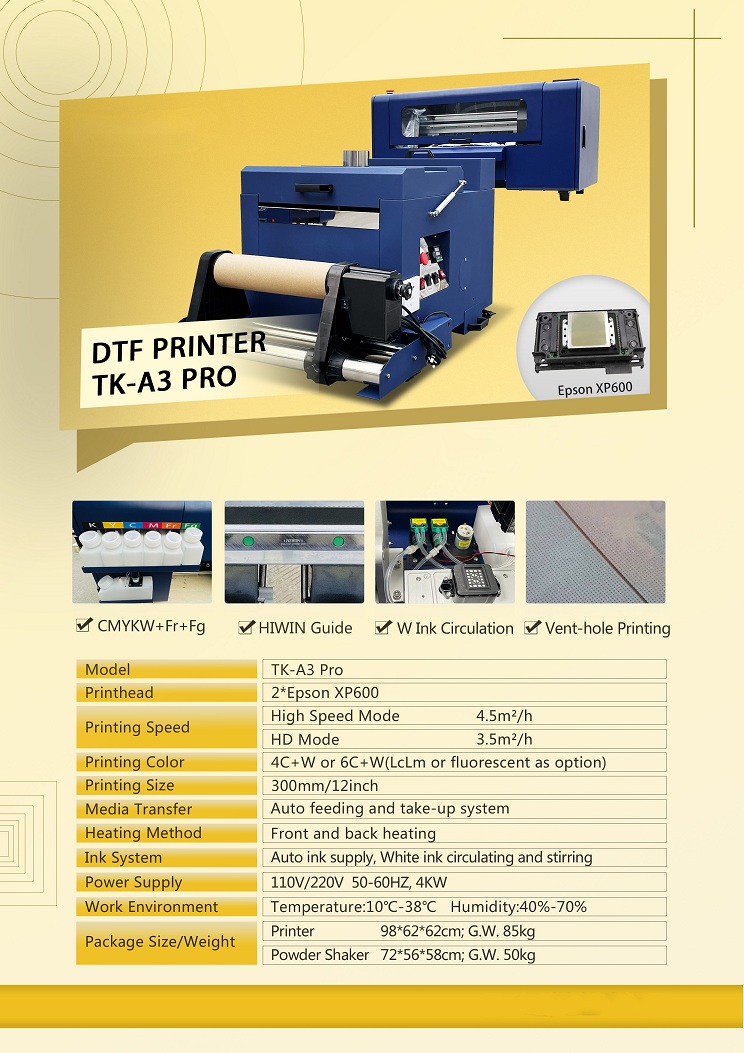

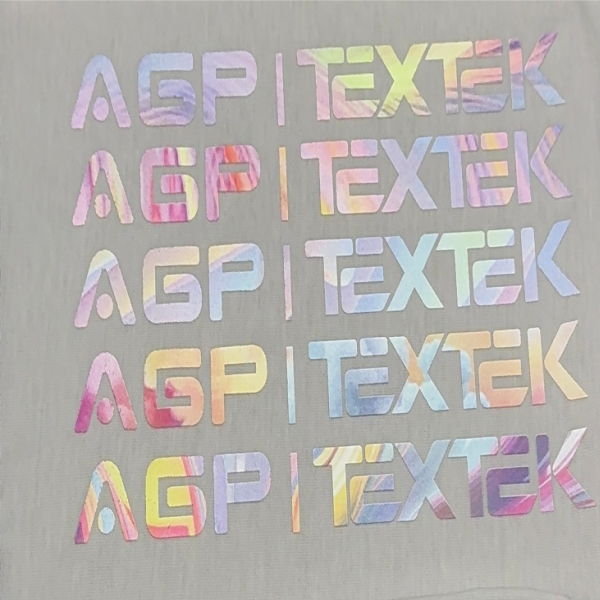

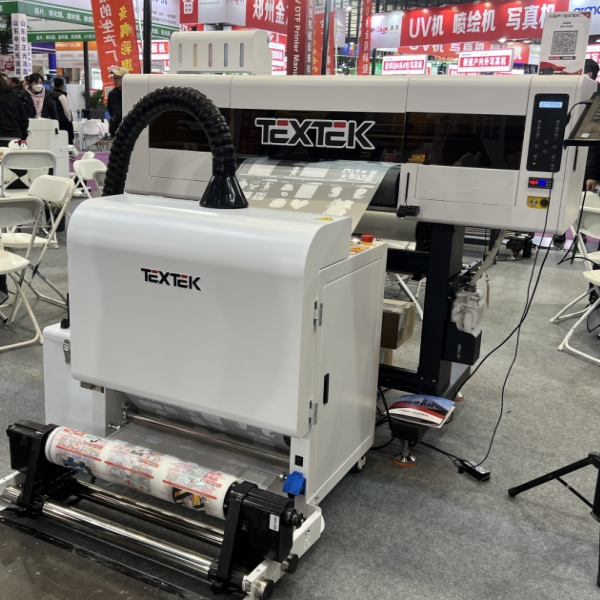

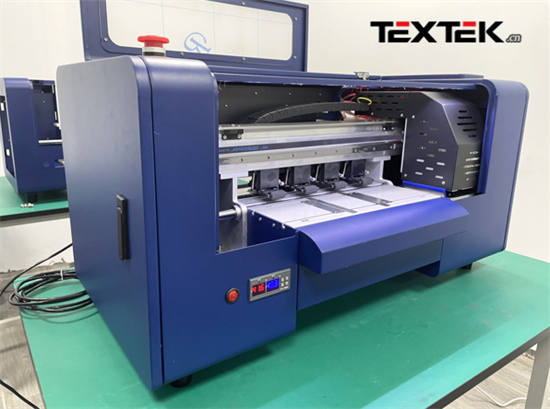

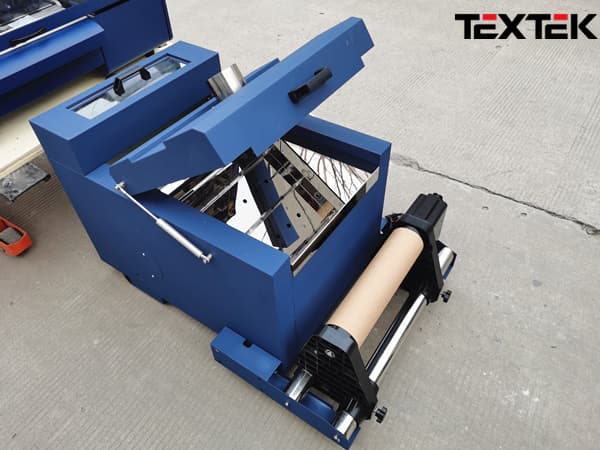

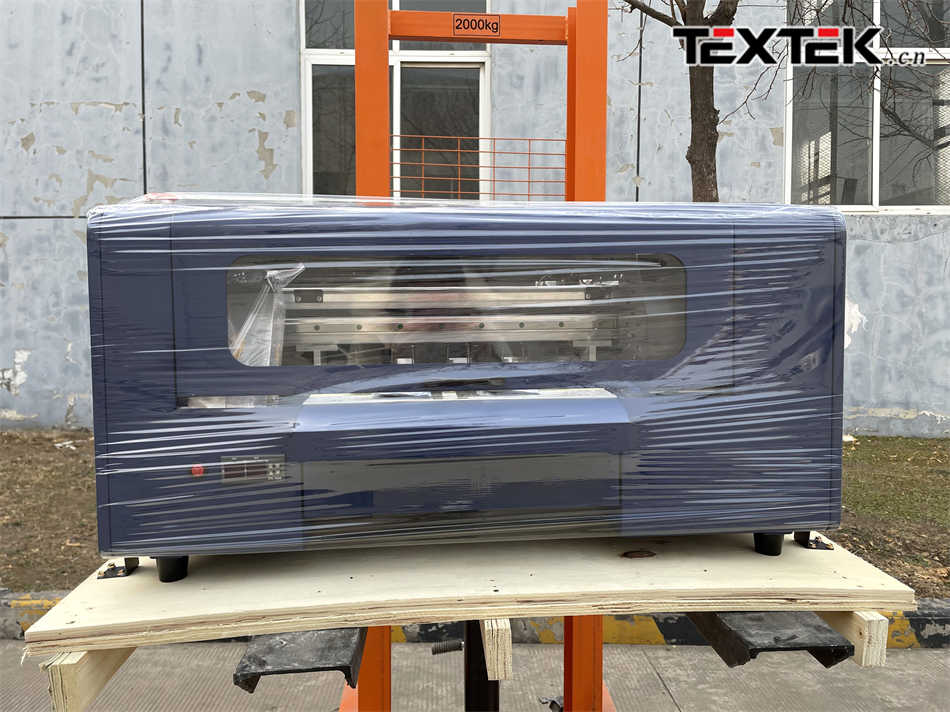

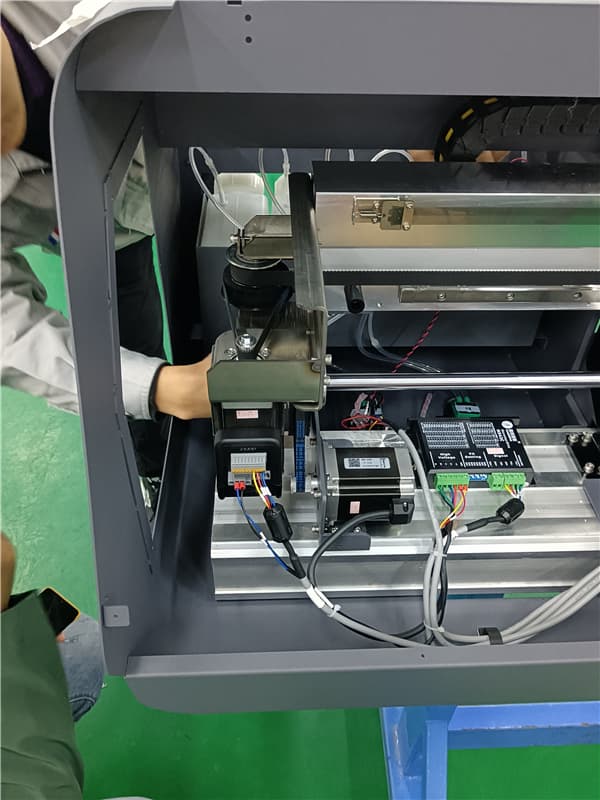

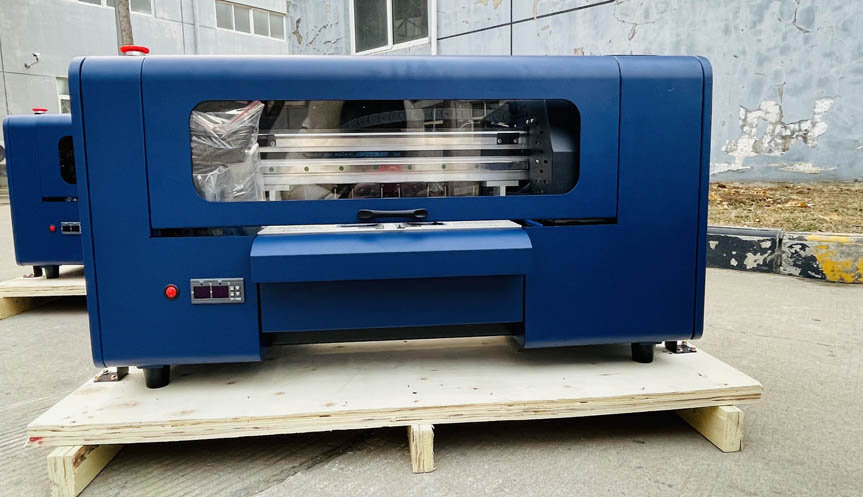

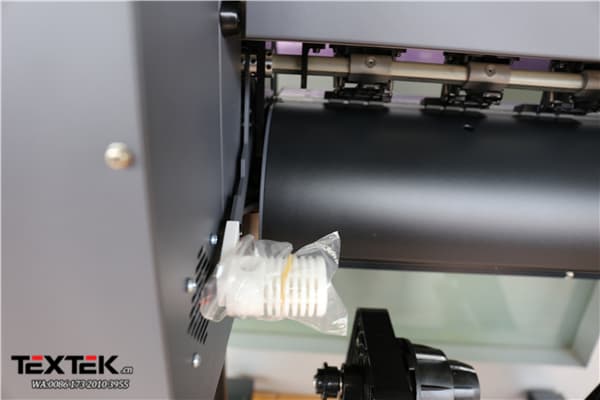

The white ink heat transfer process is widely used, not limited to fabrics, not limited to patterns. Because white ink heat transfer uses a transfer process, any fabric can be directly transferred, which is very simple. The production process of white ink heat transfer is also relatively simple. Only one white ink heat transfer and powder shaker is a production line, and one person can complete the entire hot stamping process.

Which is the best way to print clothes? The preferred white ink heat transfer printing machine. White ink heat transfer is green and environmentally friendly, free of hollowing and waste discharge. It is the most used process in the new generation of garment printing.